Brick transferring device and brick paving machine

A transfer device and brick laying machine technology, applied in roads, road repairs, roads, etc., can solve problems such as large working space, inability to work, unfavorable use of efficient brick laying operations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

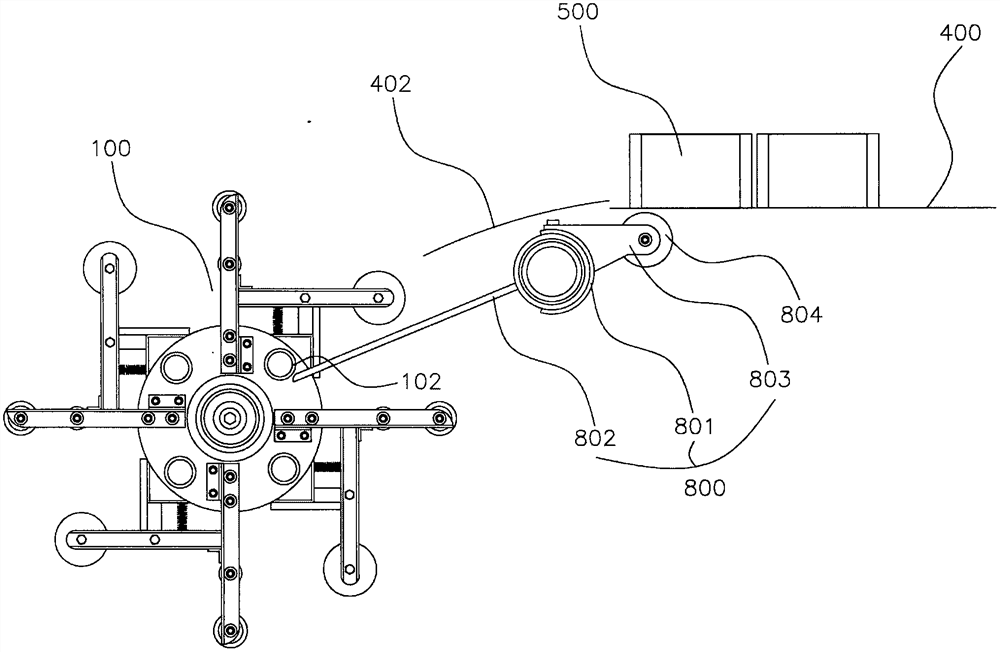

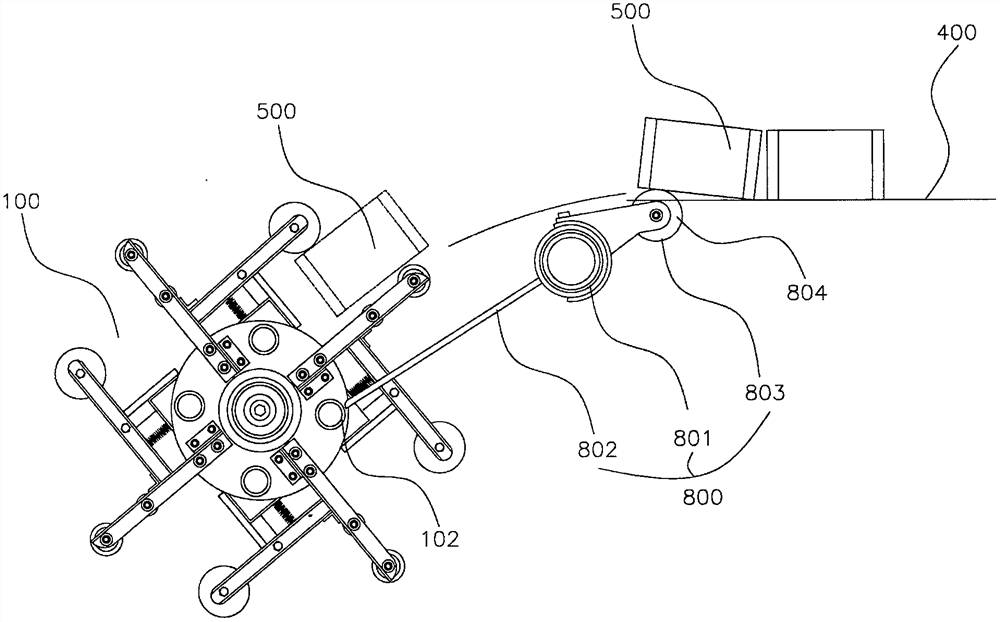

[0040] Such as Figure 1 to Figure 7 As shown: this embodiment provides a brick transfer device and a brick laying machine, including a brick laying machine 900 and its brick feeding mechanism, which mainly solves the problem that the length of the brick feeding mechanism is too long, and the brick feeding mechanism includes a first The conveying device 400, the second conveying device 600 and the brick transfer device 100, by rationally laying out the first conveying device 400 and the second conveying device 600, the conveying device mainly adopts a double-speed chain, and relies on the brick transfer device 100 to realize two The delivery of bricks 500 between them, so as to achieve the ideal design goal, the spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com