Full-automatic grid inserting machine

A slotting machine, fully automatic technology, applied in packaging and other directions, can solve the problems of difficult positioning, inconvenient operation, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

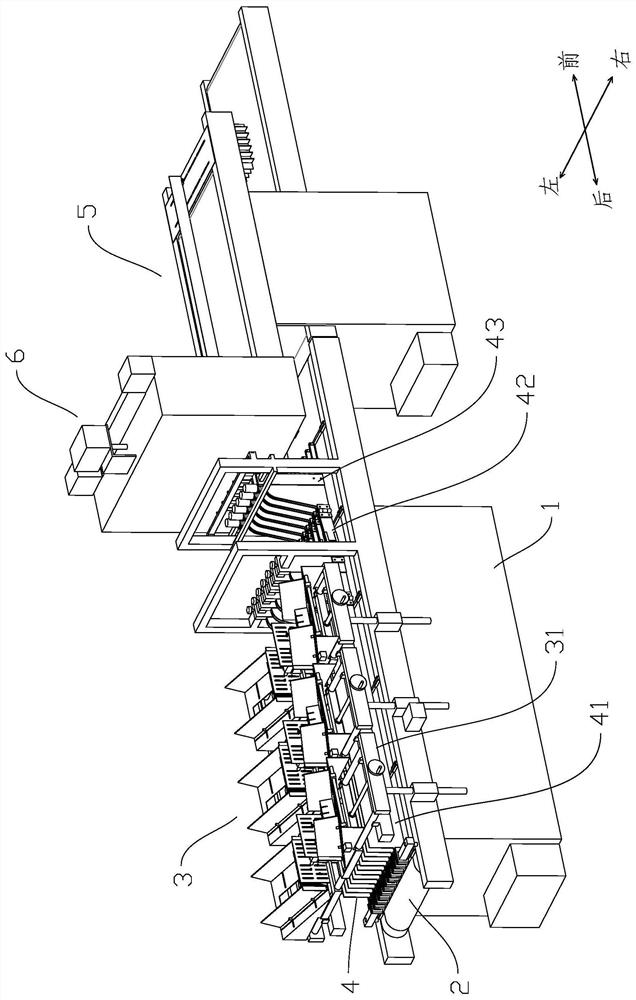

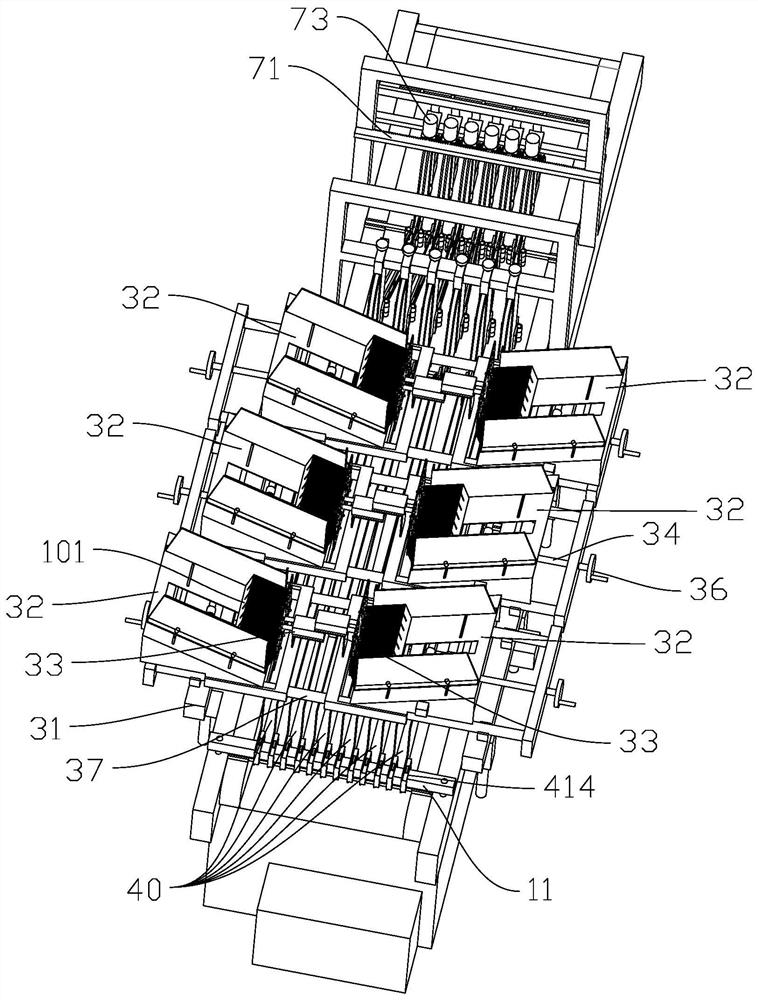

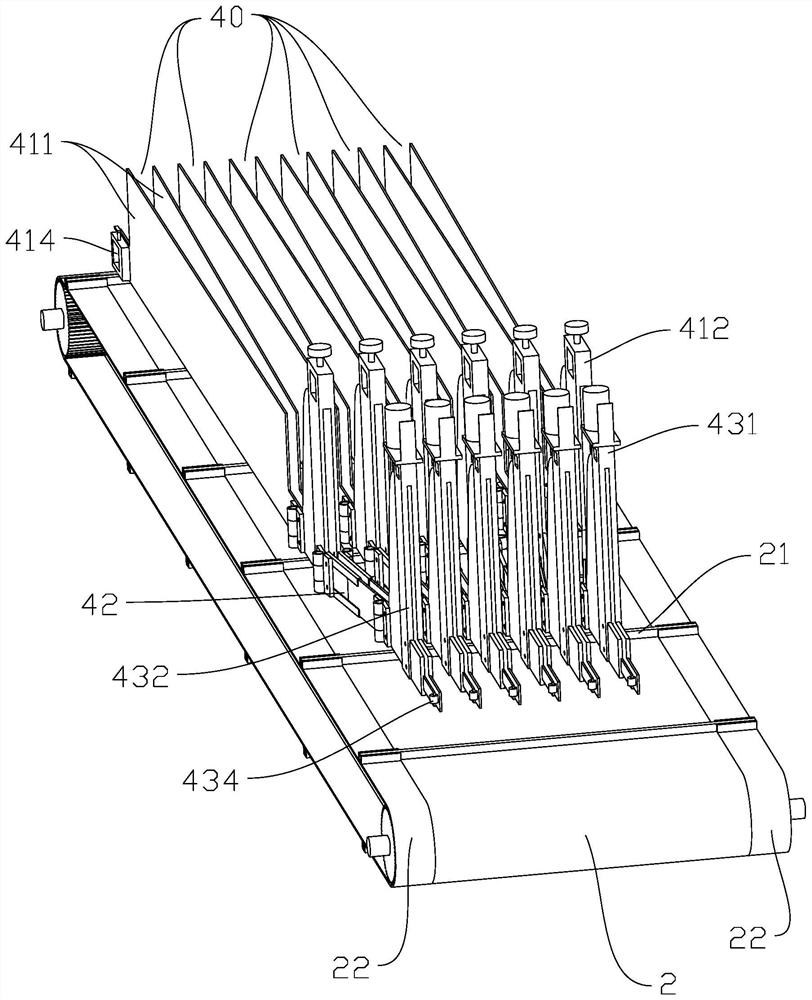

[0033] like Figure 1 to Figure 9 A full-automatic inserting machine shown includes a frame 1, and the frame 1 is provided with a main conveyor belt 2 arranged front and rear and a longitudinal partition 101 capable of inputting a plurality of left and right spaced longitudinal partitions 101 on the main conveyor belt 2. A partition feeding mechanism 3, above the main conveyor belt 2 is provided with a plurality of longitudinal partitions 101 spaced apart left and right and a guide mechanism 4 that moves forward with the main conveyor belt 2, above the front end of the main conveyor belt 2 is provided The horizontal partition feeding mechanism 5, and the grid insertion mechanism 6 that inserts the horizontal partitions 102 on the horizontal partition feeding mechanism 5 downward one by one, when a plurality of vertical partitions 101 move to the insertion mechanism 6 with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com