Fuse tube plug-in mounting device

A technology for fuses and mounting boards, which is applied in the direction of assembling printed circuits, electrical components, and printed circuits with electrical components. It can solve the problems of low production efficiency and mixed materials for manual insertion of fuses, and avoid difficulties in wiring and air pipe distribution. The effect of eliminating mixing and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the purpose, structure and function of the present invention, a fuse inserting device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

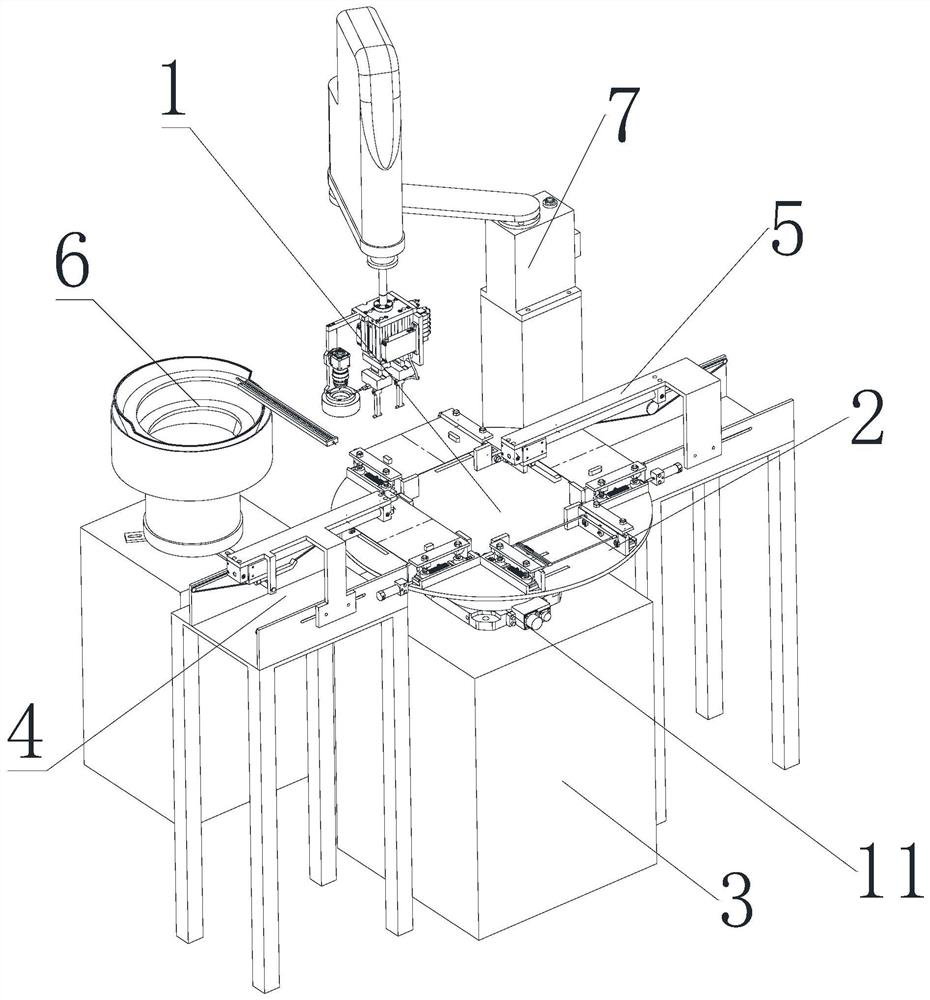

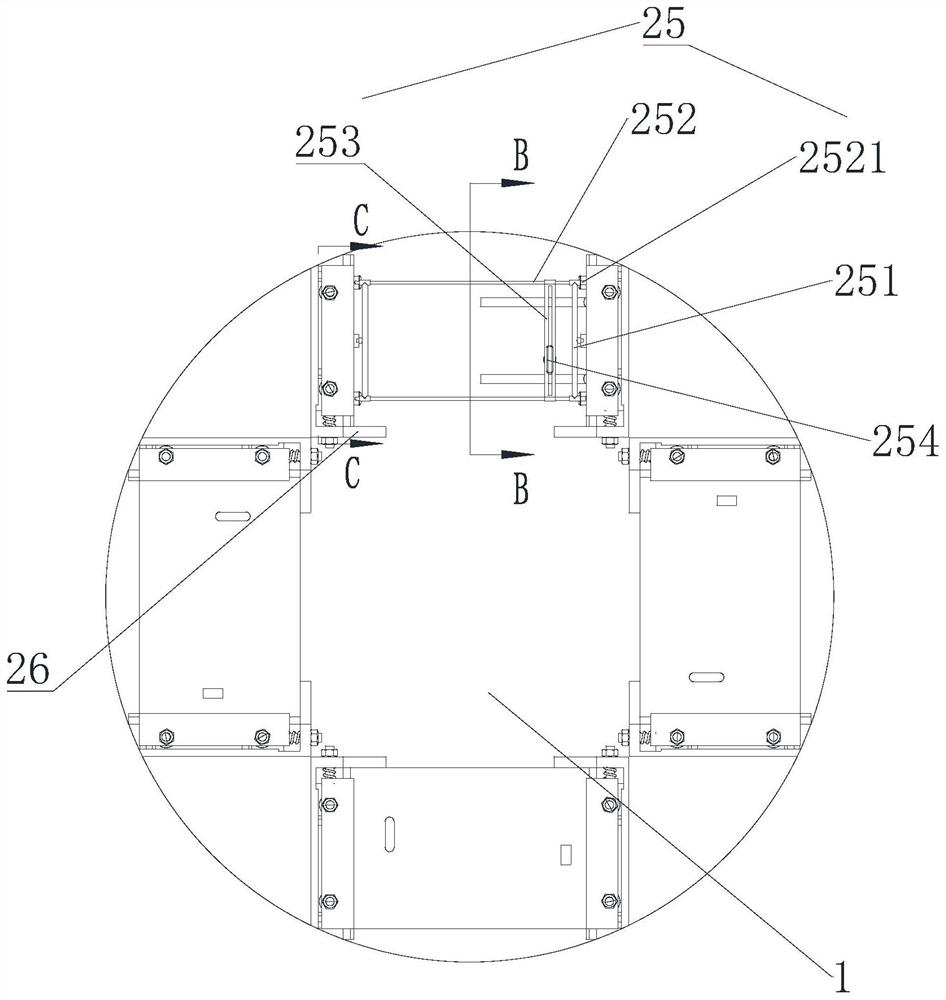

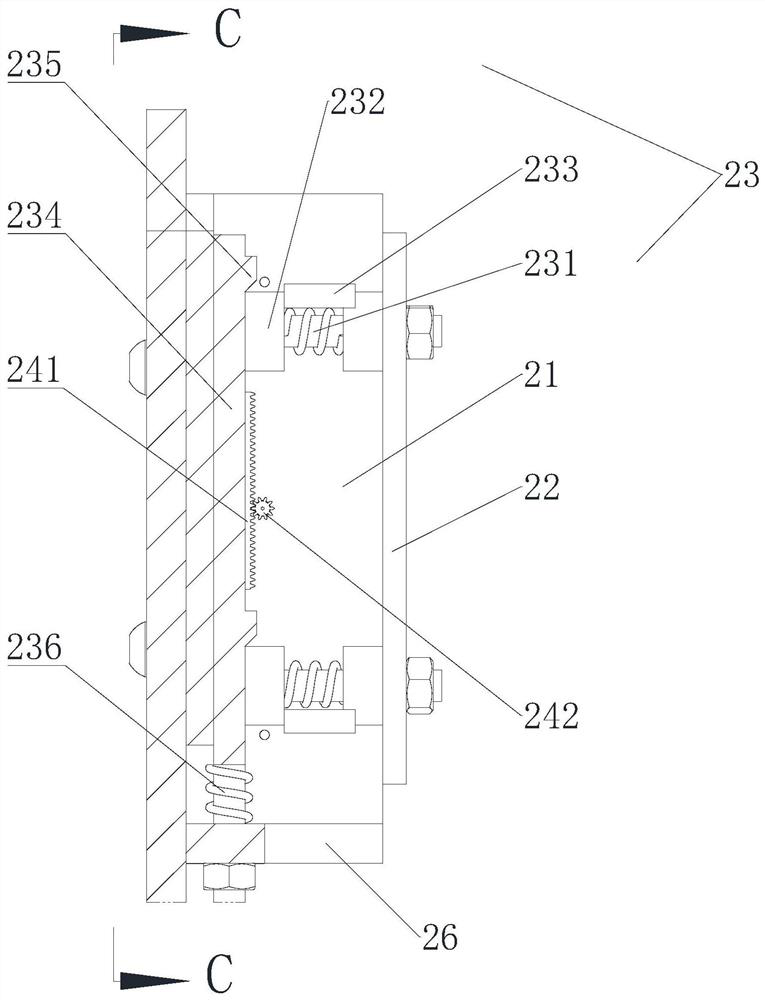

[0027] Such as figure 1 As shown, the present application provides a safety tube insertion device, including a turntable 1, on which a plurality of sets of tooling fixtures 2 for fixing PCB boards are arranged, along the direction of rotation of the turntable 1, the outer sides of the turntable 1 are respectively provided with board-in connectors. The barge mechanism 4, the insertion mechanism 7 and the board output connection mechanism 5, the board entry connection mechanism 4 pushes the PCB board into the tooling fixture 2 of the loading station of the turntable 1, the insertion mechanism 7 absorbs the fuse, and puts the fuse The tube is inserted into the safety tube seat of the PCB board, and the discharge connection mechanism pushes the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com