Jet type fuse insulation operating rod

The technology of jet fuse and insulating operating rod is applied in the field of jet fuse insulating operating rod and insulating pull rod, which can solve the problems of affecting the reliability of power supply, prolonging the power outage time of users, inconvenient for manual disassembly and assembly of jet fuse, etc. Achieve the effect of enhancing the scope of use, improving installation efficiency, and facilitating installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

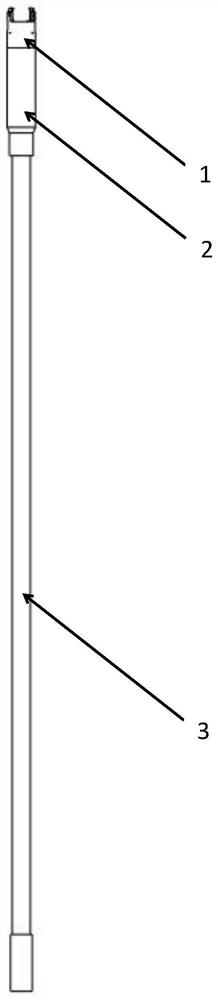

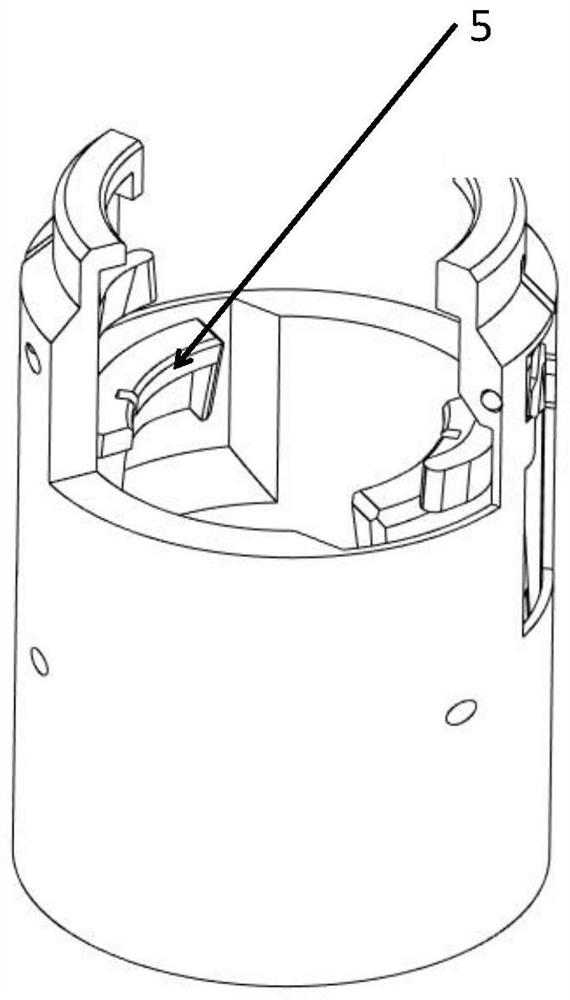

[0031] An insulated operating rod for a spray type fuse, which includes an insulating pull rod 3, and its innovation is that it also includes an extension tube 2 and a clip joint 1. An extension tube is threaded on the upper part of the insulation pull rod, and the upper end of the extension tube is The snap joint is installed on the thread; the snap joint is mainly composed of a cylinder body 10, a snap arc plate 4, a holding tooth 15 and a claw 5, and there are spaced and oppositely arranged gaps on the upper end surface of the cylinder body. The arc plates are clamped, and there are installation openings 9 on the cylinder wall directly below the two clamping arc plates, and holding teeth are installed in each installation opening through the first torsion spring, and the inner wall of the cylinder below each holding tooth Both of them are equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com