Fabricated material mixing device for building construction and use method

A technology of building construction and mixing device, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of inconvenient work for operators, low mixing efficiency of materials, and reduction of work quality at subsequent construction sites. Functionality and ease of use, reduction of operational processes and waiting times, effect of increasing finished product accuracy and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

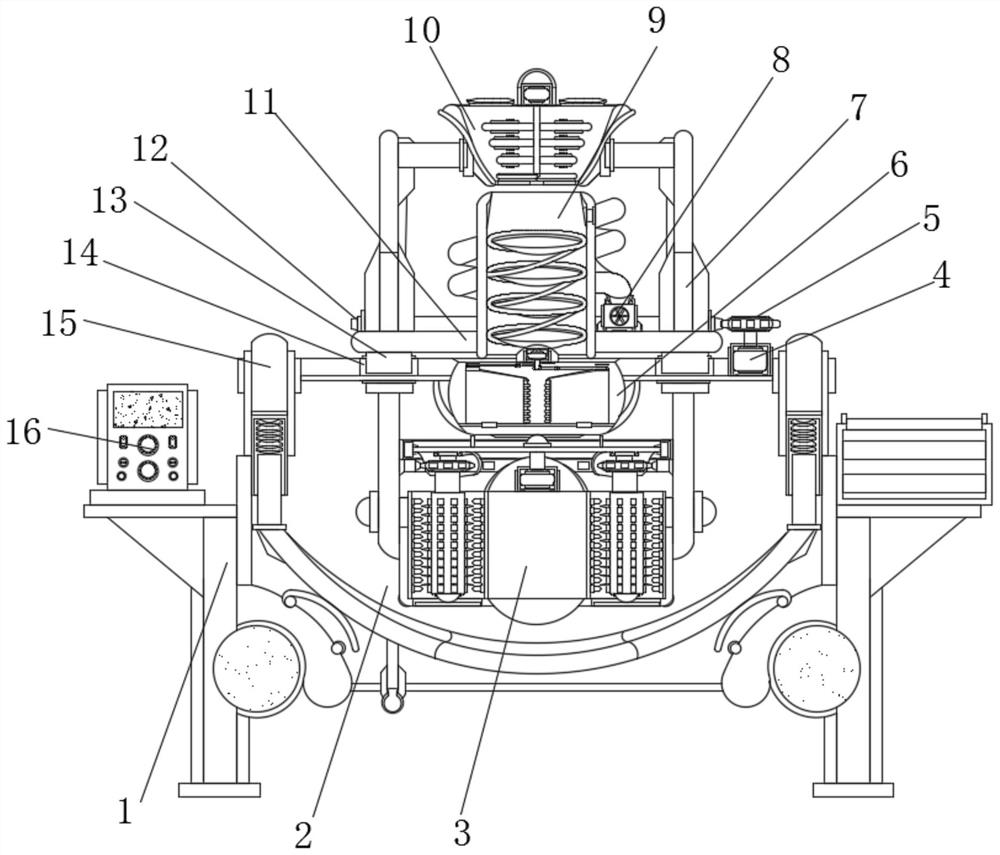

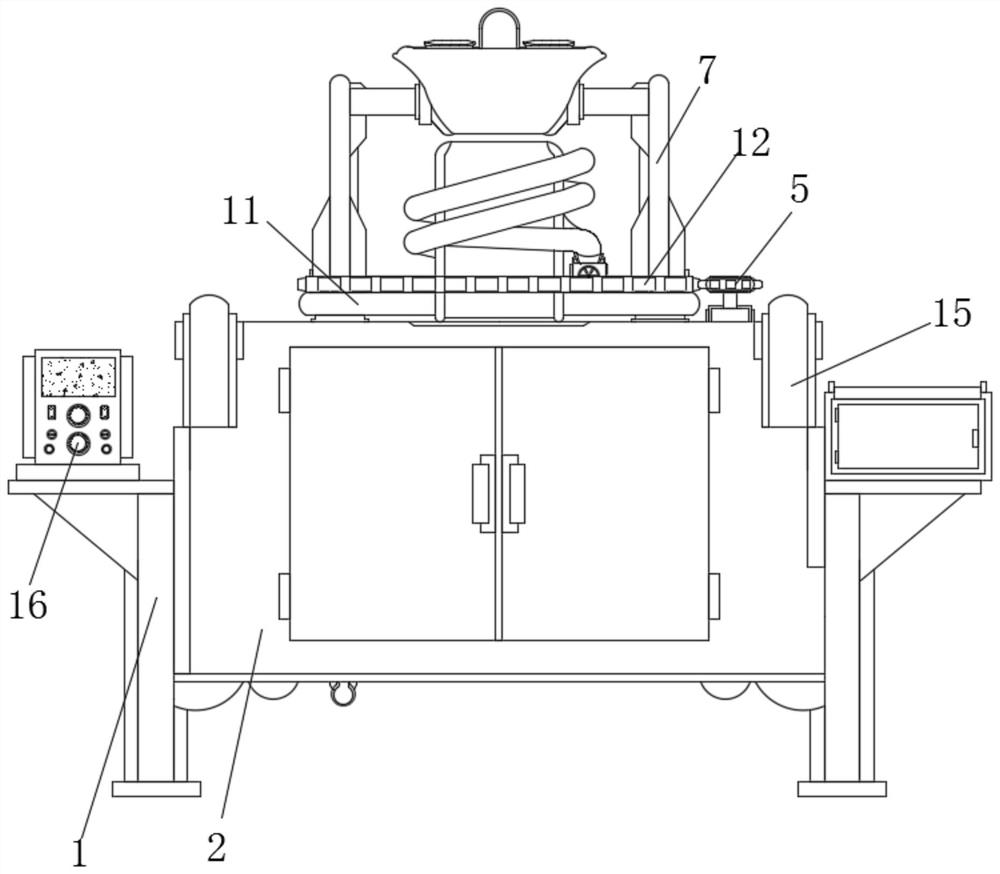

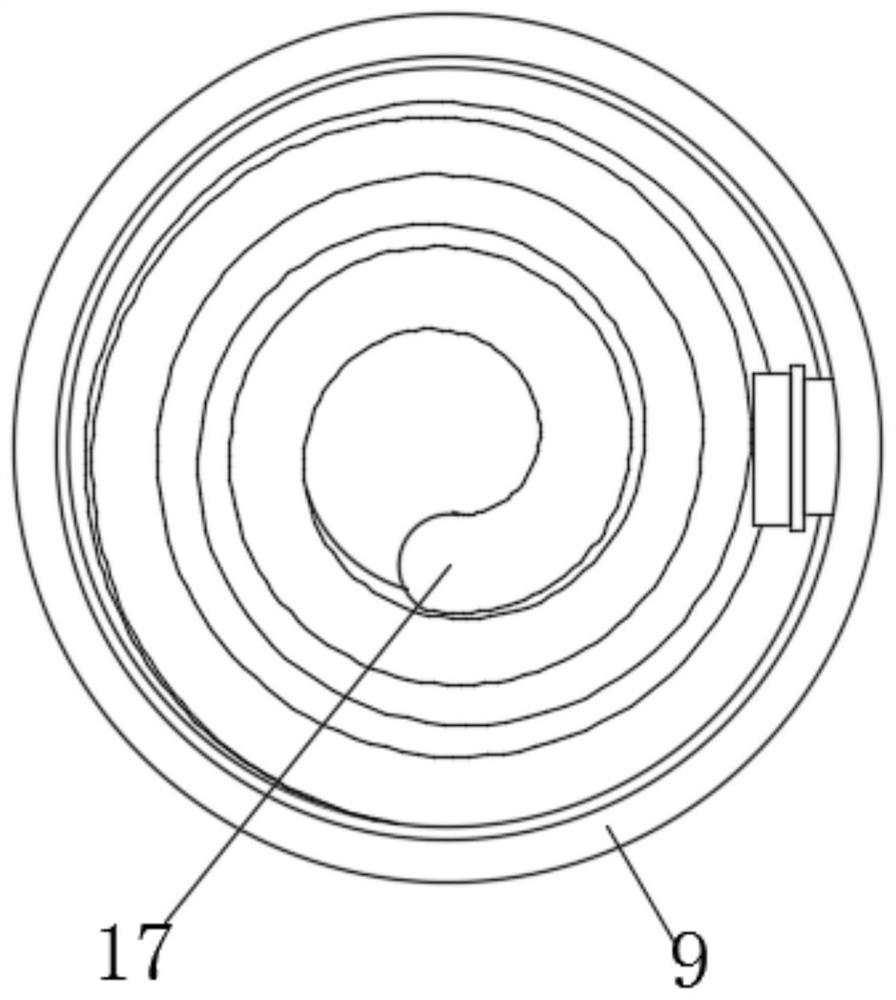

[0039] see Figure 1-10 , the present invention provides a technical solution: a prefabricated building construction mixing device, including a machine base 1, the machine base 1 is two groups, and the side of the two groups of machine bases 1 close to each other is provided with a body 2 connected to each other, Both sides of the body 2 are provided with mounting columns 15 interconnected with the machine base 1, fixed frames 22 are provided on both sides of the top inside the body 2, and a stirring and mixing assembly is provided at the bottom of the two groups of fixed frames 22 close to each other. 2 The inner side of the top is provided with an annular chute B14, and the top of the annular chute B14 is provided with a sliding block B13 that cooperates with each other. There is a mounting frame 7, an external gear ring 12 is provided on the outside of the top of the mounting plate 11, and the external gear ring 12 is connected to the mounting frame 7, a servo motor 4 is pr...

Embodiment 2

[0046] see Figure 1-10 , the present invention provides a technical solution: a prefabricated building construction mixing device, including a machine base 1, the machine base 1 is two groups, and the side of the two groups of machine bases 1 close to each other is provided with a body 2 connected to each other, Both sides of the body 2 are provided with mounting columns 15 interconnected with the machine base 1, fixed frames 22 are provided on both sides of the top inside the body 2, and a stirring and mixing assembly is provided at the bottom of the two groups of fixed frames 22 close to each other. 2 The inner side of the top is provided with an annular chute B14, and the top of the annular chute B14 is provided with a sliding block B13 that cooperates with each other. There is a mounting frame 7, an external gear ring 12 is provided on the outside of the top of the mounting plate 11, and the external gear ring 12 is connected to the mounting frame 7, a servo motor 4 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com