Full-automatic paint spraying and drying line

A drying line, fully automatic technology, applied in spray booths, spray devices, etc., can solve the problems of difficulty in guaranteeing spray quality, low work efficiency, and difficult operation, and achieve high spray efficiency, reasonable structure design, and spray quality Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0029] Specific embodiments of the invention will be described in detail below.

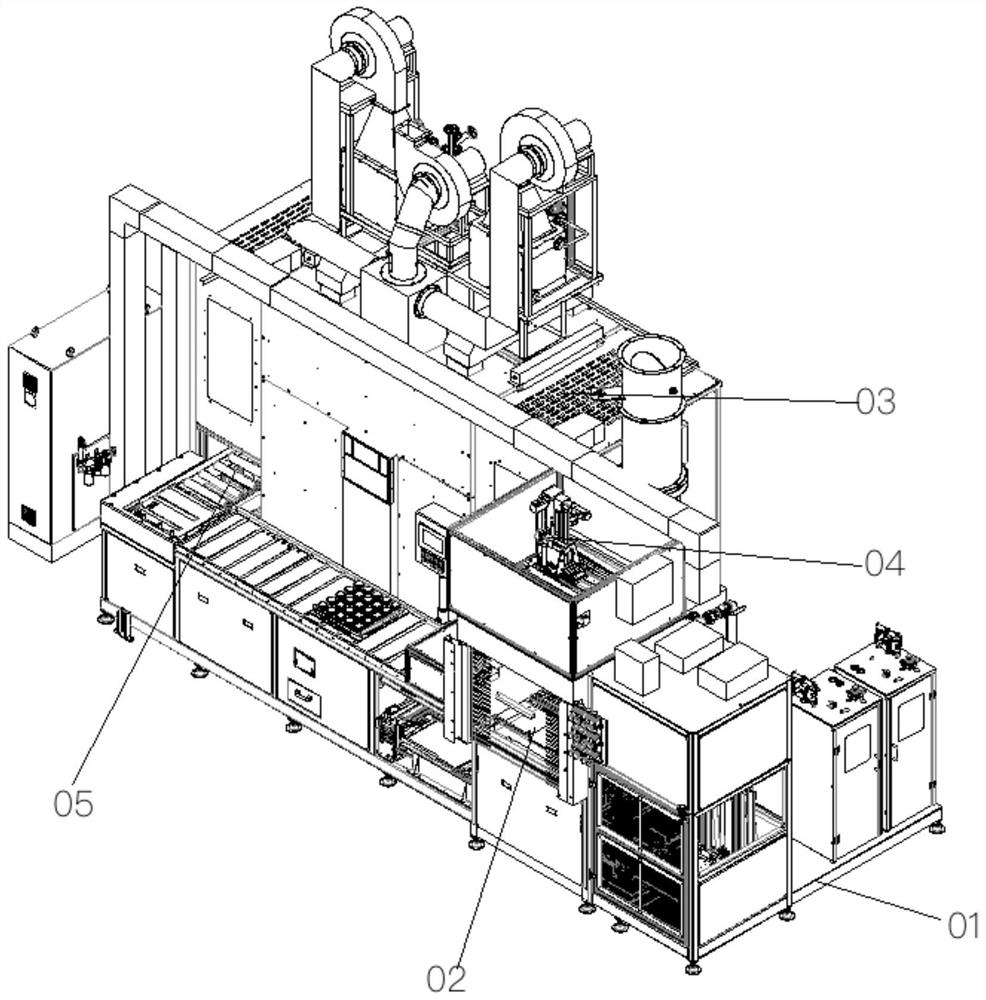

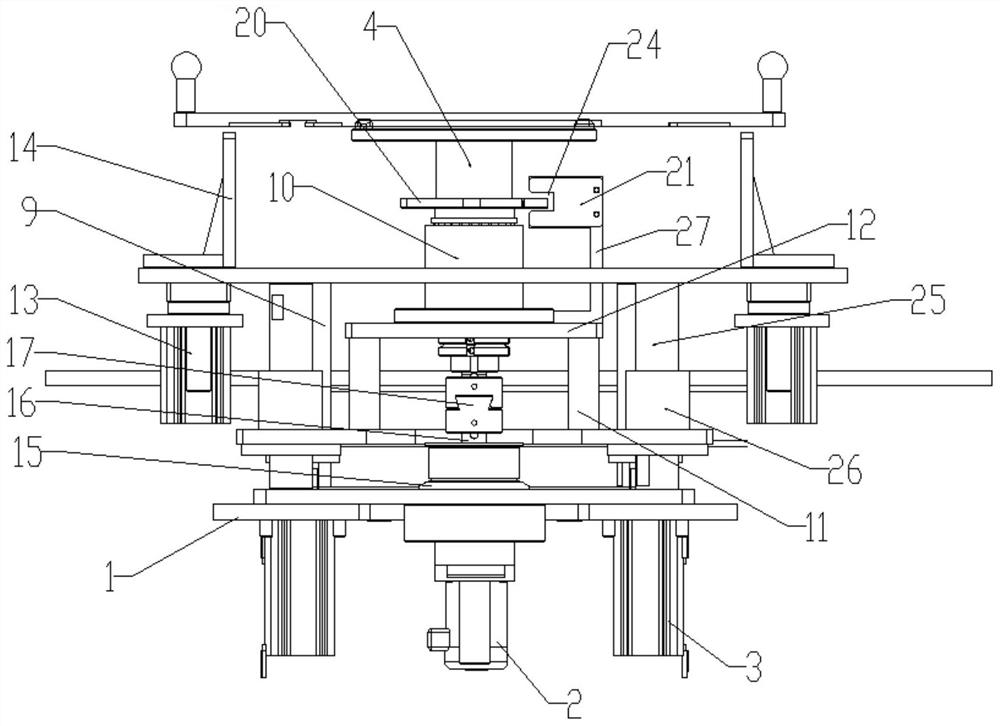

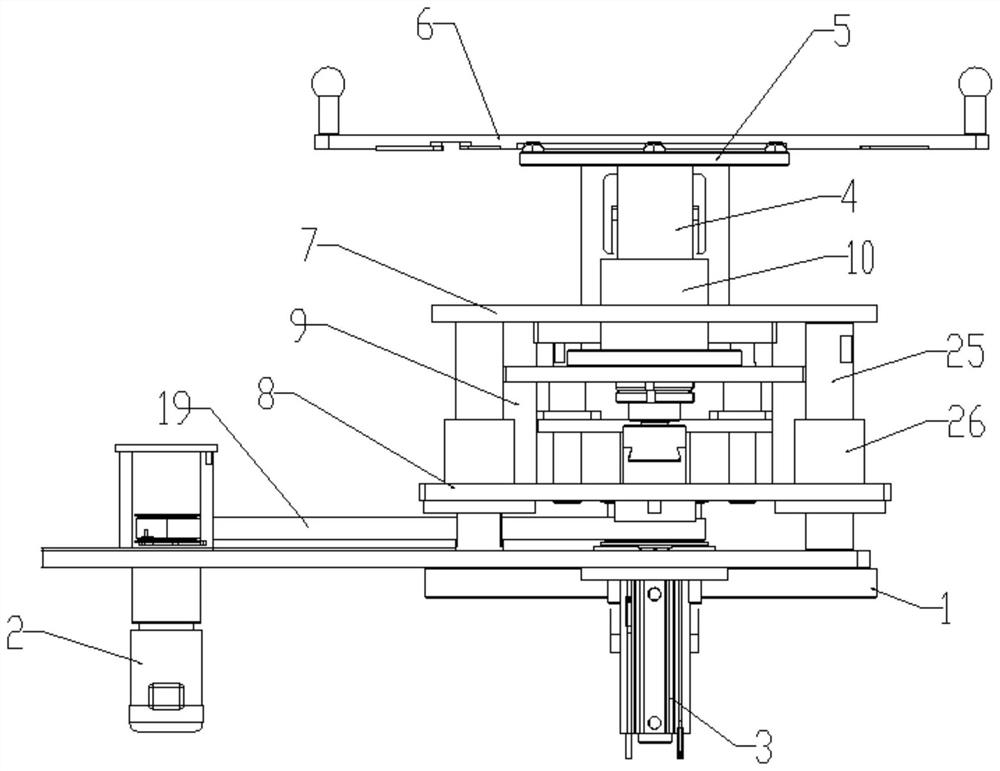

[0030] A fully automatic paint drying line, such as Figures 1 to 8 As shown, including the equipment platform 01, the equipment platform is provided with a spraying room 02 and a drying room 03, and the corresponding spraying room is provided with a spraying manipulator 04, and the workpiece fixture in the spraying room is transferred to the drying room by the spraying manipulator; There is a workpiece discharge station 05 on the side; a rotary jacking device is provided in the spraying chamber, and workpiece fixtures are installed on the upper part of the rotary jacking device; The working platform corresponds to several fans for blowing air on the working platform. In addition, generally multiple sets of heating devices are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com