Rotor blade of a wind turbine, comprising an insulator layer and a protective layer

A technology of rotor blades and wind energy equipment, which is applied in wind energy generation, mechanical equipment, conductor discharge/power consumption, etc., and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

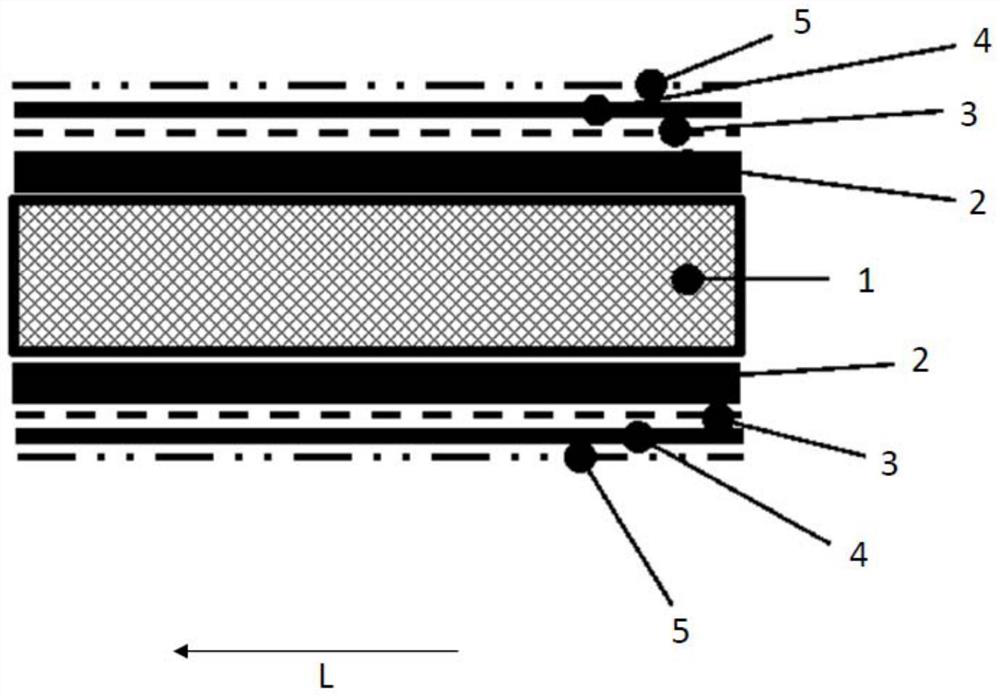

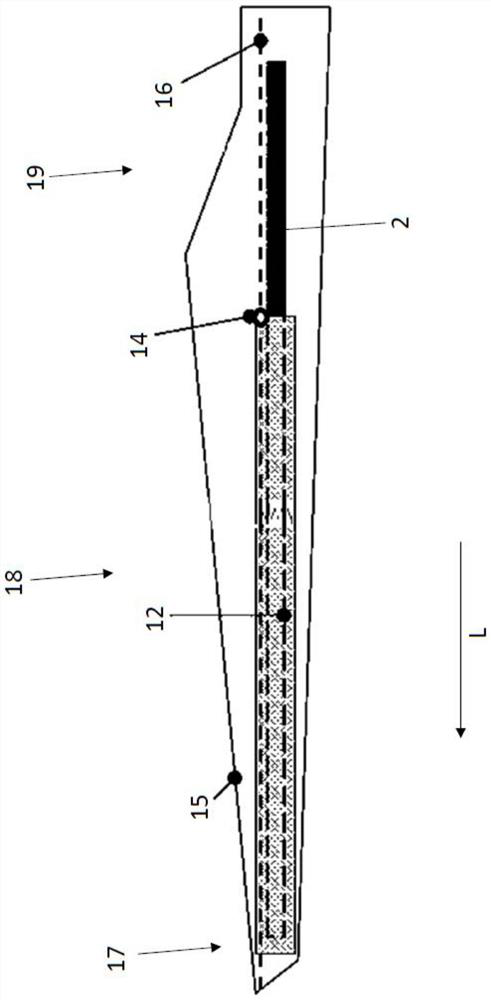

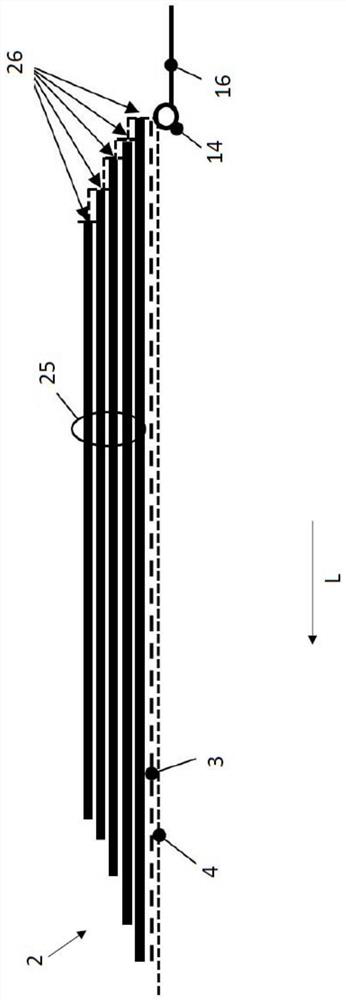

[0029] figure 1 A schematic view of a portion of a longitudinal section of a rotor blade 15 along a web 1 , in particular a main web, is shown. The web 1 is arranged between the rotor blade surface 5 on the suction side and the pressure side. The rotor blade surface 5 delimits the respective suction-side or pressure-side rotor blade half shell to the outside. figure 1 The structure in is mirror-symmetrical, and layers and features on the suction and pressure sides are denoted by the same reference numerals.

[0030] The rotor blade half-shells consist of a laminated structure with an electrically conductive protective layer 4 on the rotor blade surface 5 on the rotor blade inner side, the electrically conductive protective layer 4 being formed according to figure 1 Embodiments of the present invention comprise carbon fibers, or even consist entirely of carbon fibers. The protective layer 4 can form the outermost layer of the rotor blade half-shell, but it is also conceivabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com