Method for measuring and evaluating jitter degree of tail end of industrial robot

An industrial robot and evaluation method technology, applied in the field of robot performance testing, can solve the problems of lack of quantitative data and indicators, affecting user experience, etc., and achieve the effect of simple collection, low equipment cost, and short measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

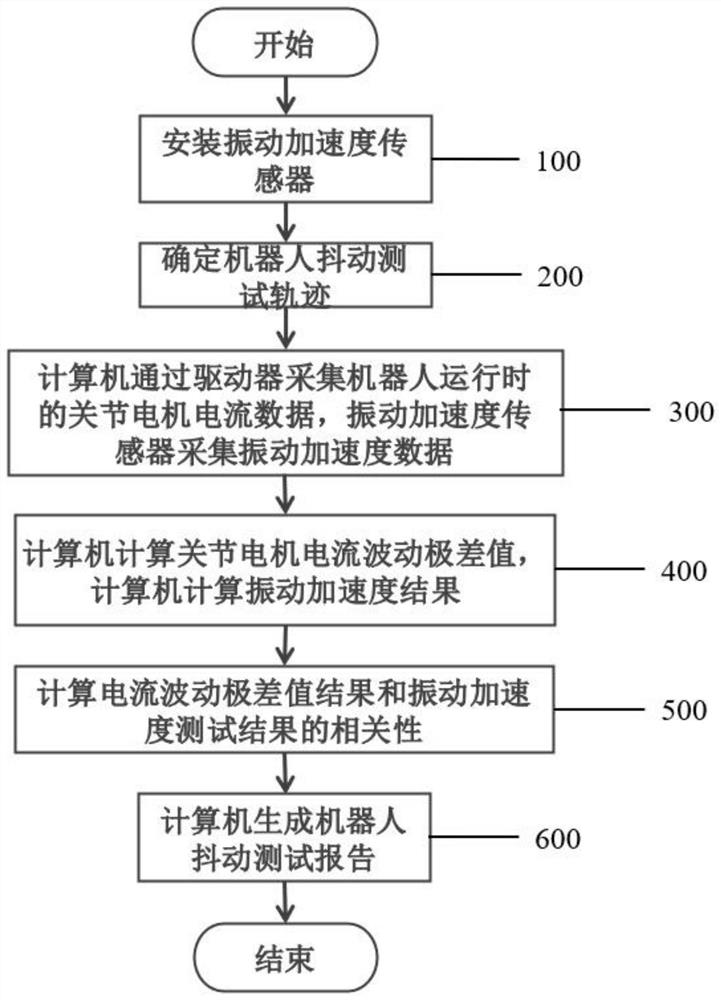

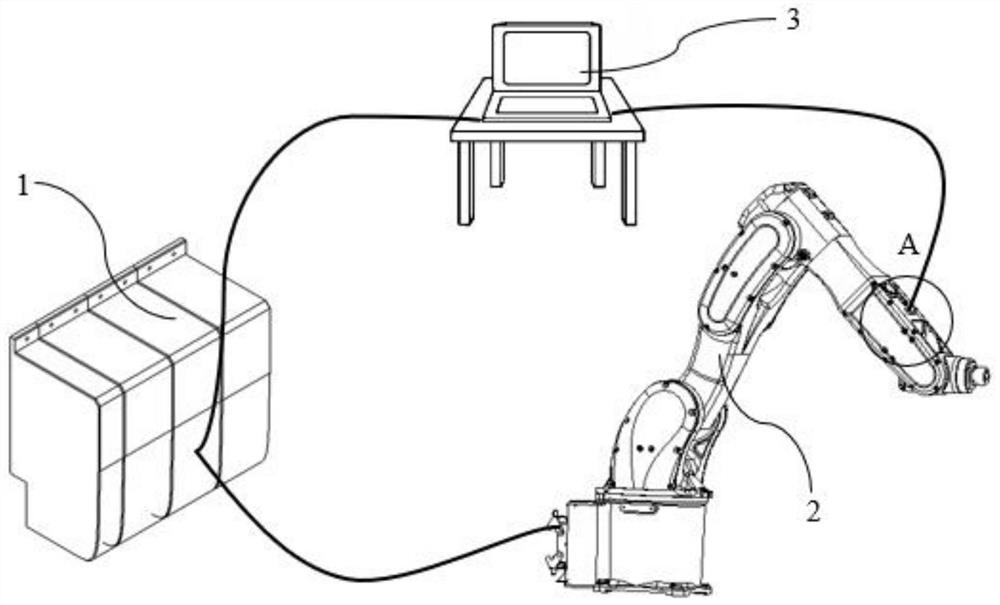

[0033] Such as Figure 1 to Figure 3 As shown, a method for measuring and evaluating the degree of shaking at the end of an industrial robot, the specific steps are as follows:

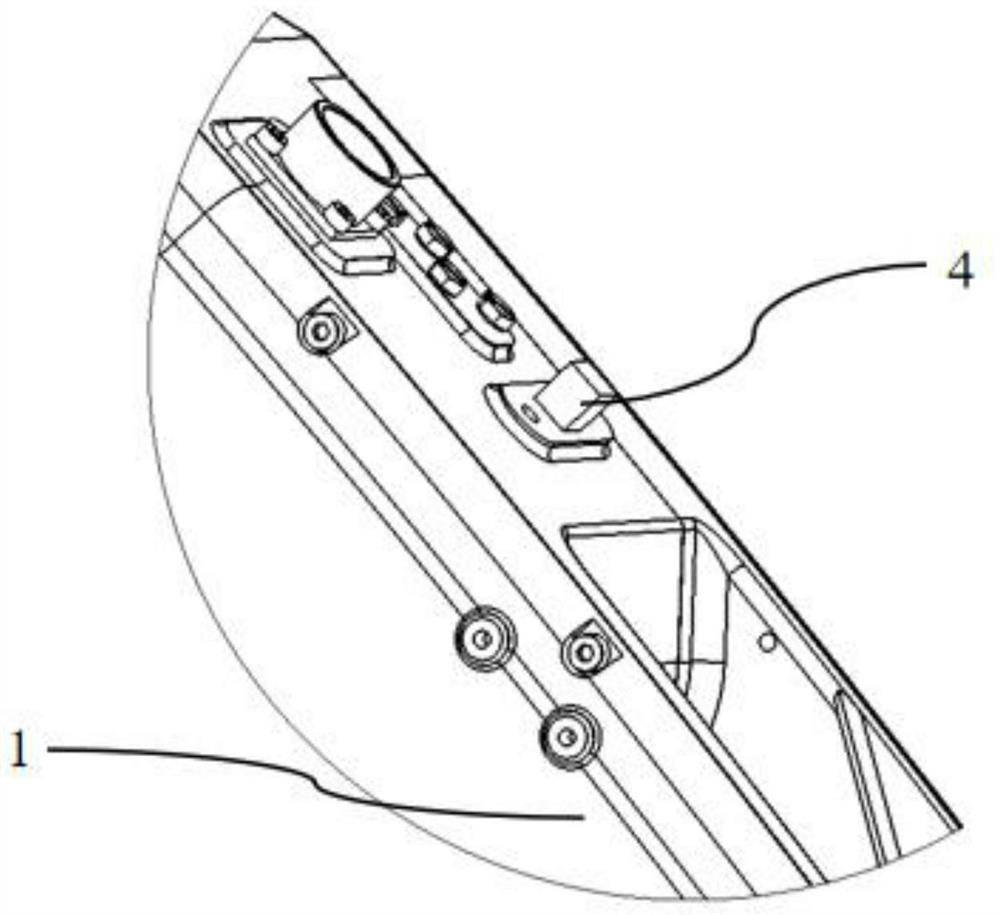

[0034] S100, installing a vibration acceleration sensor;

[0035] S200. Determine the robot shake test track;

[0036] S300, the computer collects the joint motor current data when the robot is running through the driver, and the vibration acceleration sensor collects the vibration acceleration data;

[0037] S400, the computer calculates the extreme difference value of the joint motor current fluctuation, and the computer calculates the vibration acceleration result;

[0038] S500, calculating the correlation between the current fluctuation extreme difference result and the vibration acceleration test resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com