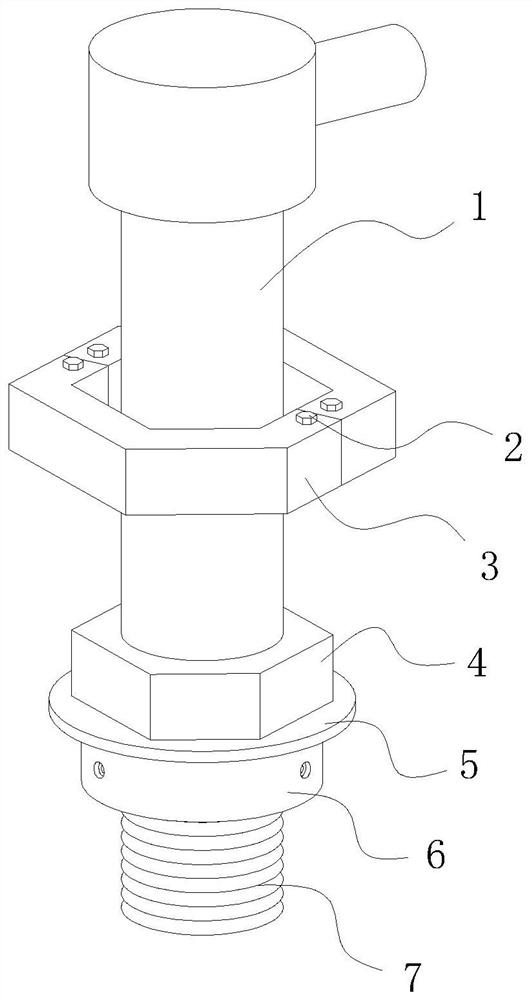

A vacuum detection device for vacuum equipment

A technology for detection devices and vacuum equipment, applied in measuring devices, vacuum gauges, measuring fluid pressure, etc., can solve problems affecting the disassembly and assembly of vacuum sensors, lack of protective measures for regular hexahedrons, wear and tear of regular hexahedrons, and achieve protection of regular hexahedrons, Easy disassembly and assembly, reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

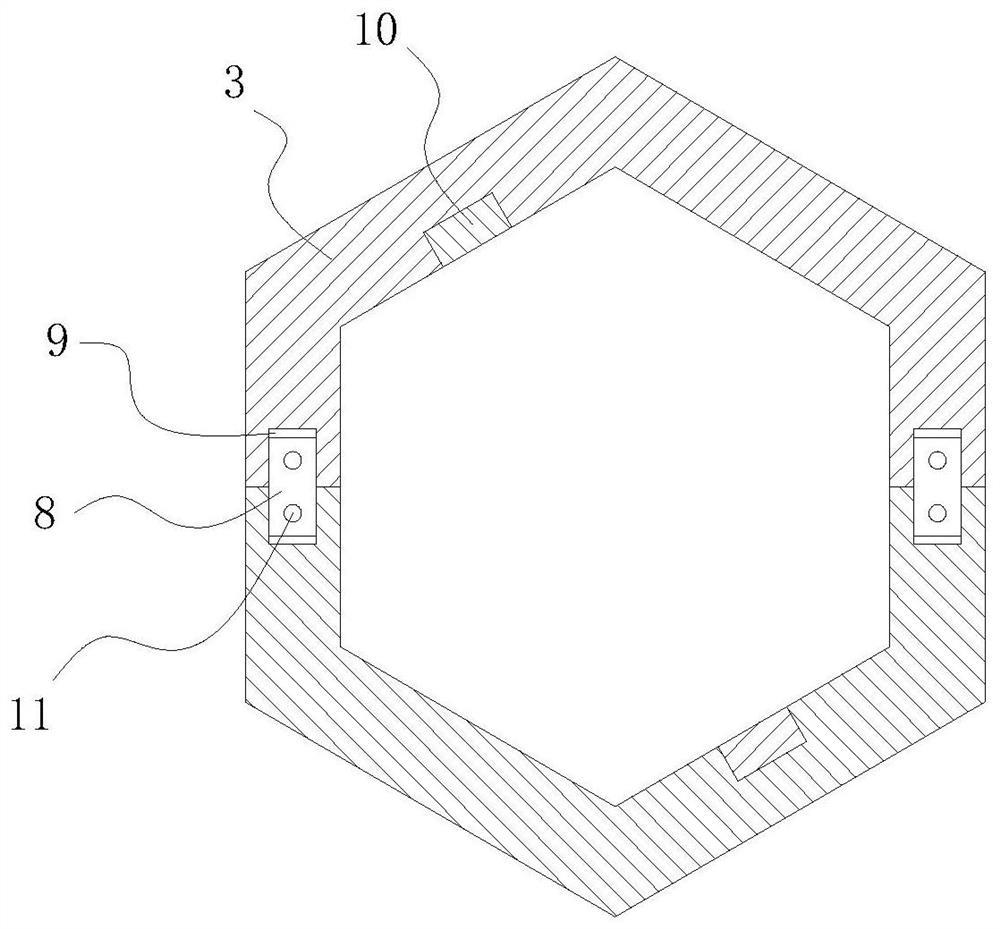

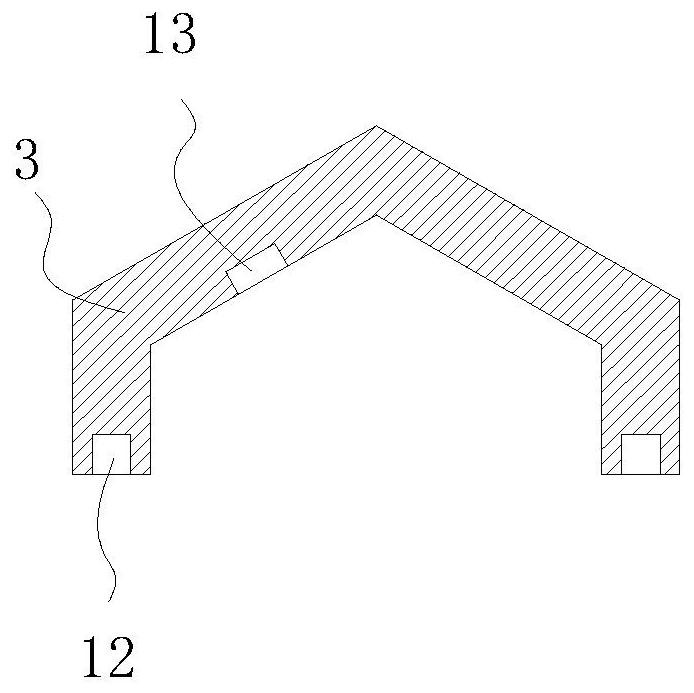

[0039] DETAILED DESCRIPTION: The two four-sided frames 3 are butted against each other, and the two ends of the strip plate 8 are respectively inserted into the strip-shaped openings 12 on the two four-sided frames 3 until the threaded holes 11 are aligned with the insertion holes 14, Then, screw the connecting screw 2 through the through hole 14 into the threaded hole 11 to complete the interconnection of the two four-sided frames 3, install the rubber pad 9 on the strip plate 8, and then insert the end of the strip plate 8 into the strip. When inside the opening 12, the rubber pad 9 is in contact with the inner wall of the opening 12, so as to prevent the strip plate 8 from falling out of the opening 12 at will. The two four-sided frames 3 are sleeved on the regular hexahedron 4, and tools such as wrenches are directly stuck on the structure formed by the two four-sided frames 3, so as to prevent tools such as wrenches from contacting the regular hexahedron 4, and play the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com