Method for accurately and reversely solving target point of heating grain by using existing temperature measurement network

A target point and hot point technology, applied in the field of grain storage, can solve the problems of stored grain loss, stored grain quality deterioration, moisture increase, etc., to increase labor costs, quickly and accurately cool down, and avoid stored grain quality deterioration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples.

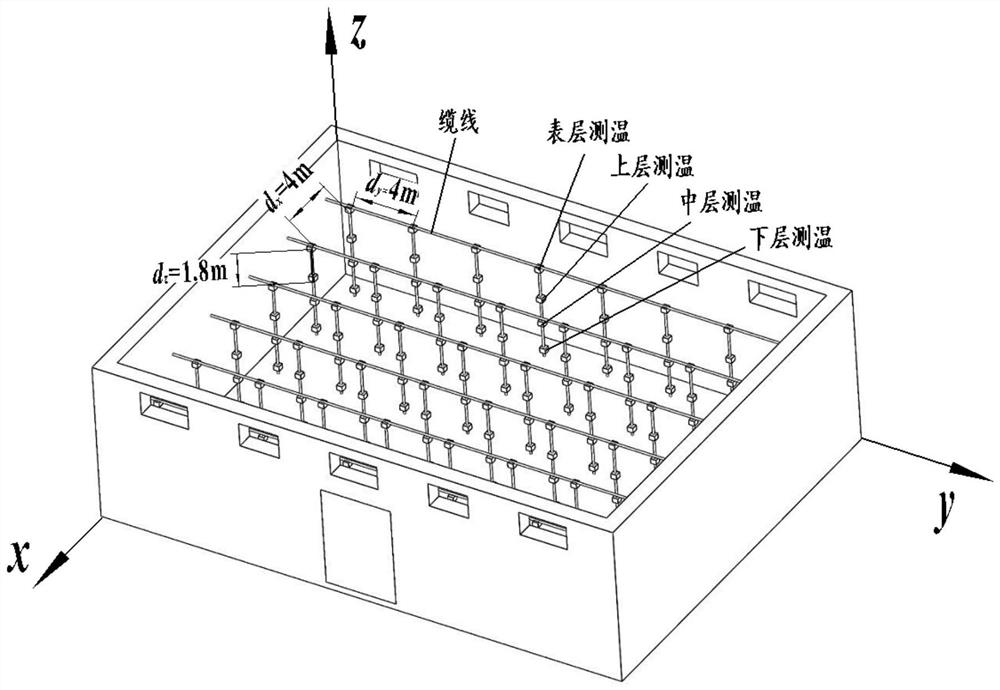

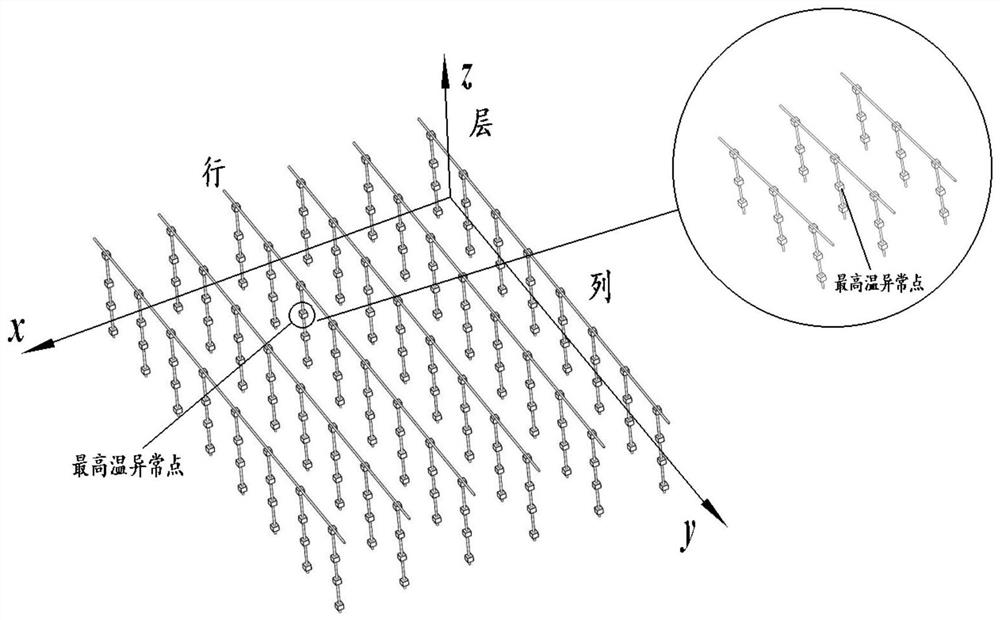

[0038] see Figure 1-Figure 2 , figure 1 is the grain storage room and its state diagram, figure 2 The temperature measurement network of each layer is composed of 6 rows, 8 columns, and 4 layers of sensor temperature measurement points. The distance between the points and the intervals is 1.5m from the warehouse wall, and the distance between the temperature measurement sensors between the rows and columns is d x = d y= 4m, the surface sensor is 0.5m away from the grain surface, the lower sensor is 0.3m away from the bottom of the silo, and the upper, middle and middle layers are equally divided. For the convenience of calculation, the layer distance d is set z = 1.8m, the height of stacked grain is 6.2m. For normal temperature grain storage bins, the normal storage tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com