Material distributing device for concrete prefabricated parts

A technology for concrete prefabricated parts and distributing devices, which can be applied to supply devices, manufacturing tools, etc., can solve problems such as poor versatility, and achieve the effects of facilitating material reclaiming, reducing failure risks, and increasing the range of activities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiment of the present application solves the technical problems of high work intensity and low work efficiency in the prior art by providing a distribution device for concrete prefabricated parts.

[0027] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

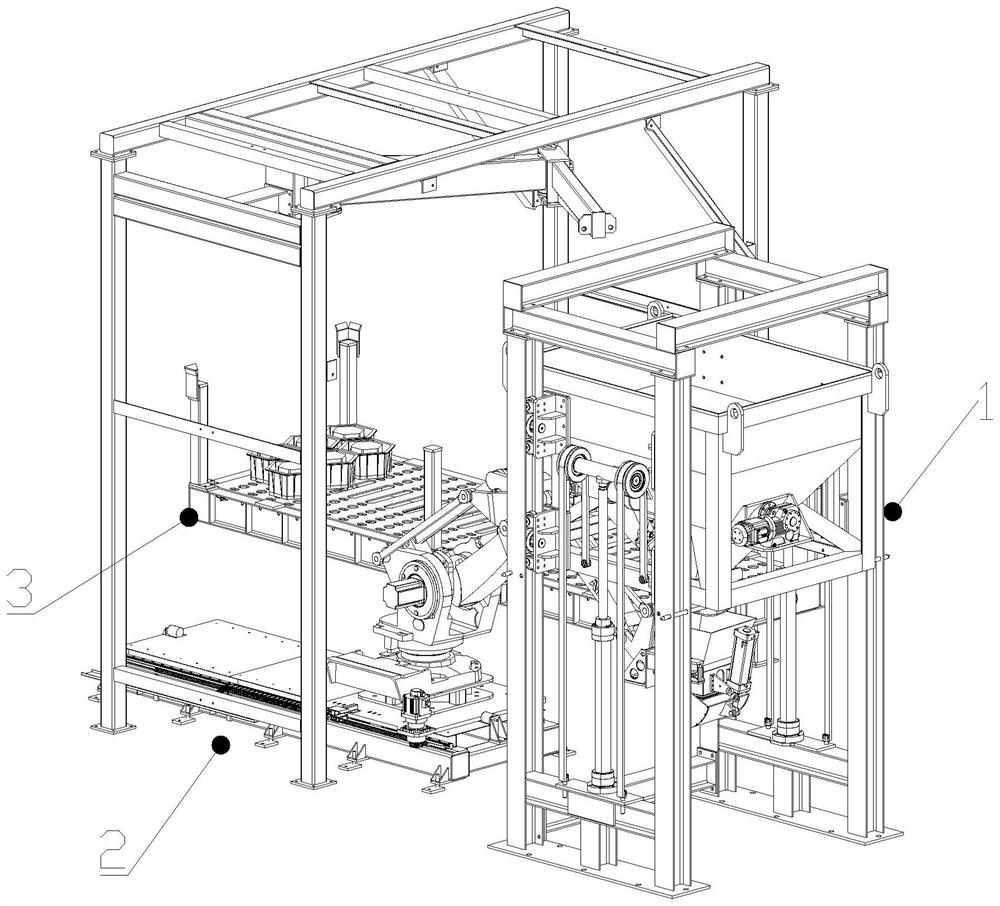

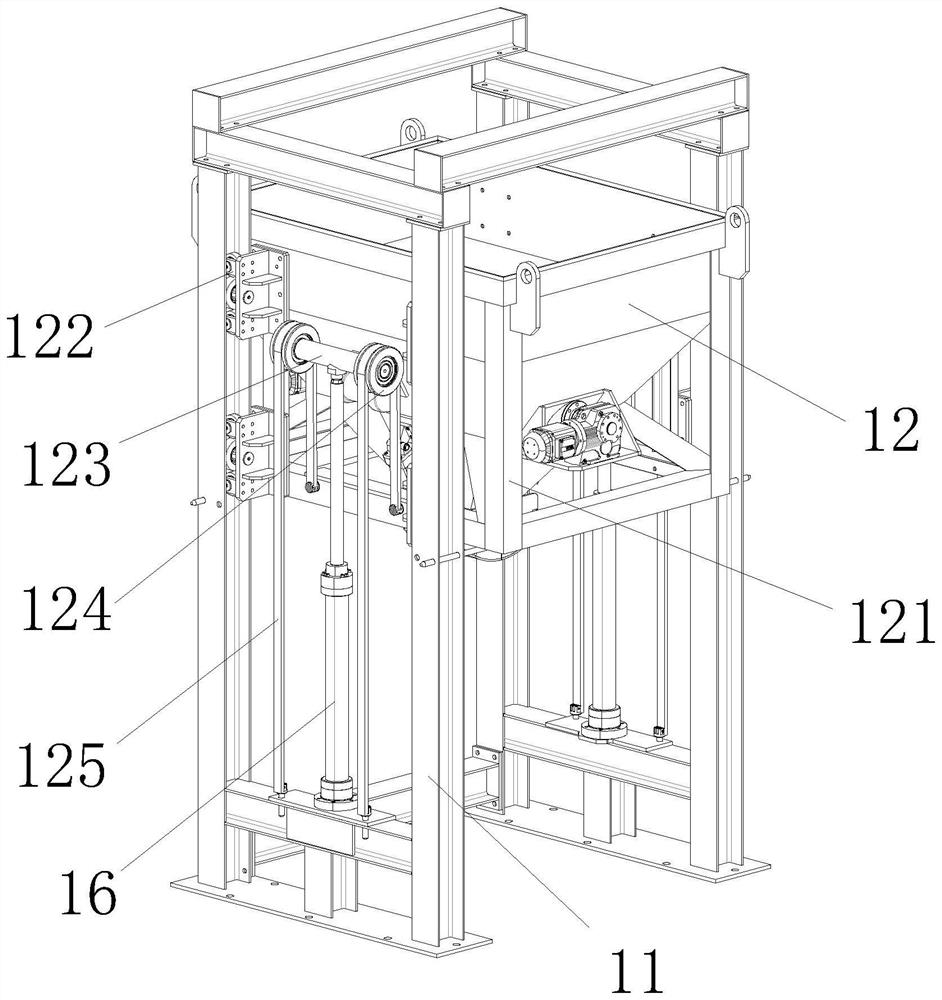

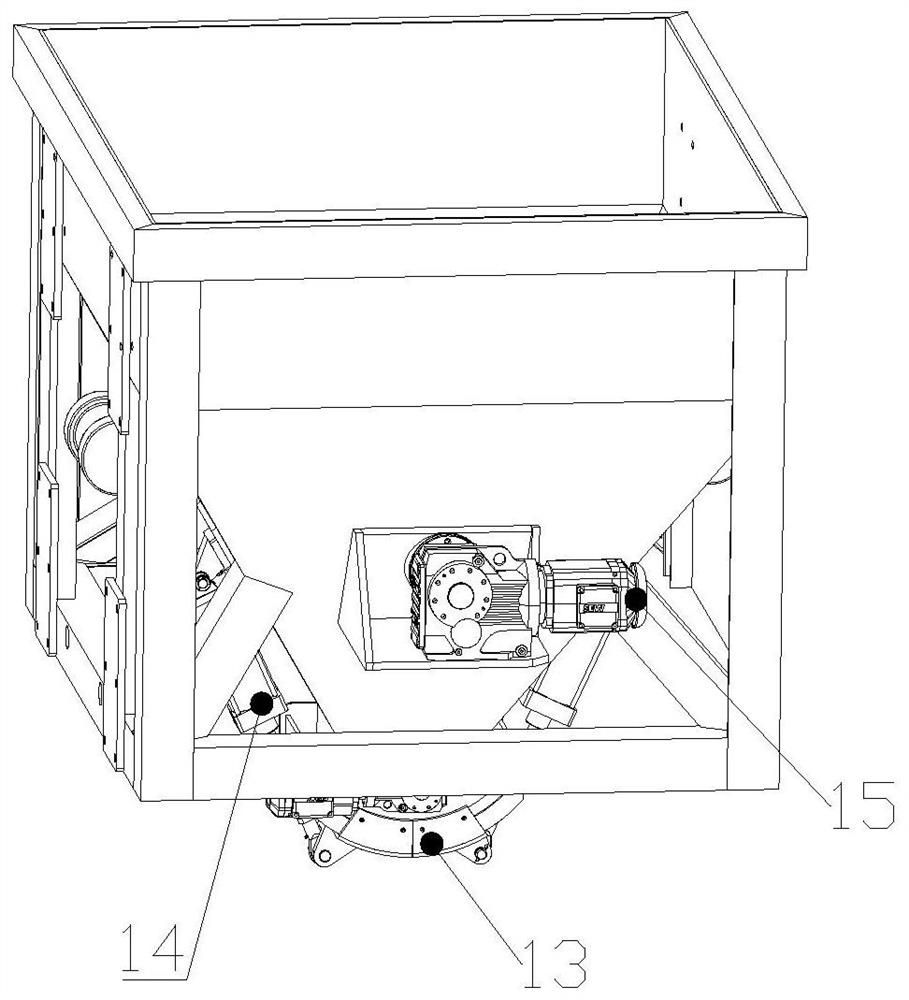

[0028] Such as Figure 1-5 As shown, a distributing device for concrete prefabricated parts includes a conveyor belt 3 for conveying prefabricated part molds, a material storage platform 1 for storing concrete, and a material distribution mechanism 2 for pouring concrete from the material storage platform 1 into the prefabricated part molds.

[0029] Described distributing mechanism 2 comprises support 21, and balance hanger 22 is installed on support 21, and balance hanger 22 ends are hoisted with installation support 23, and installation support 23 is provided with distribution hopper 24, and distributi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com