IGCC power station gasification furnace hydrogenation system and working method thereof

A technology of hydrogenation system and gasifier, which is applied in the direction of electrical components, circuit devices, AC network circuits, etc., can solve the problems of limited variable load capacity, peak shaving depth and response rate that cannot meet the requirements of the power grid, etc., and achieve quality improvement , increase operating efficiency and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

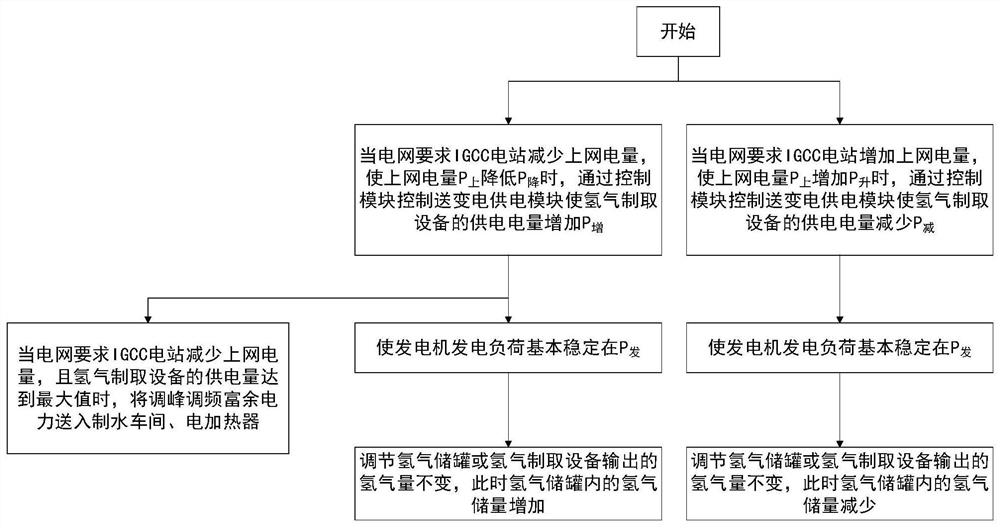

[0037] The embodiment of the present invention provides a gasifier hydrogenation system for an IGCC power station and its working method, which has the characteristics of rapidly changing the power supply and load at any time, and meets the peak and frequency regulation load requirements of the IGCC power station by the power grid.

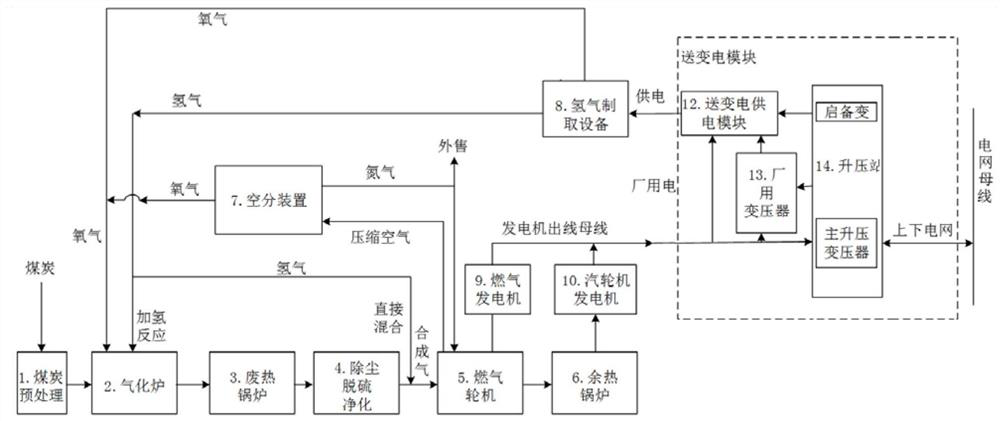

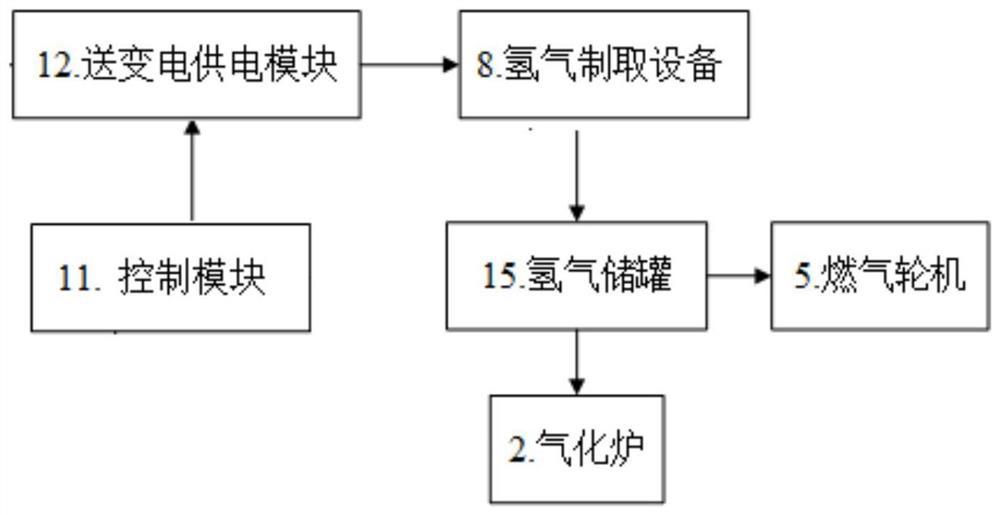

[0038] One, such as figure 1 and 2 As shown, the IGCC power plant gasifier hydrogenation system includes an IGCC power plant power generation system, a control module 11 , a power transmission and transformation power supply module 12 , hydrogen production equipment 8 and a hydrogen storage tank 15 . The power generation system of the IGCC power station is used as a power source to be electrically connected to the power transmission and transformation power supply module 12, and the power transmission and transformation power supply module 12 is electrically connected to the hydrogen production equipment 8.

[0039] The hydrogen outlet of the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com