Efficient energy-saving draught fan convenient to overhaul

A high-efficiency energy-saving fan technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of motor damage, large power distribution of the motor, and easy entry of foreign objects, etc., to achieve stable current, reduce operating costs, and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

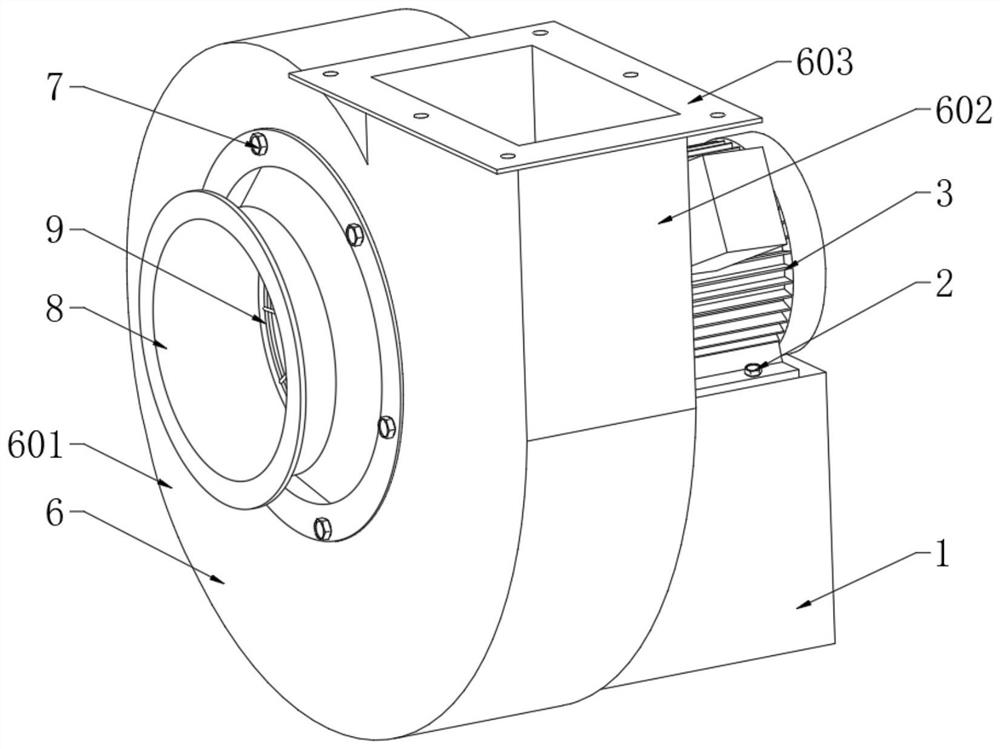

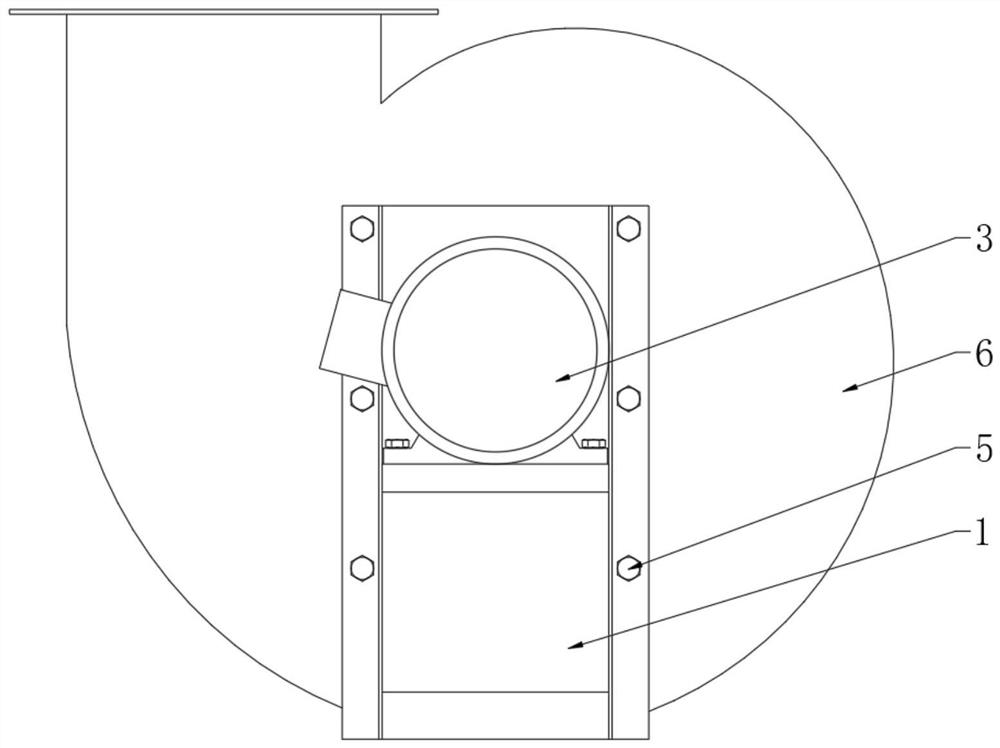

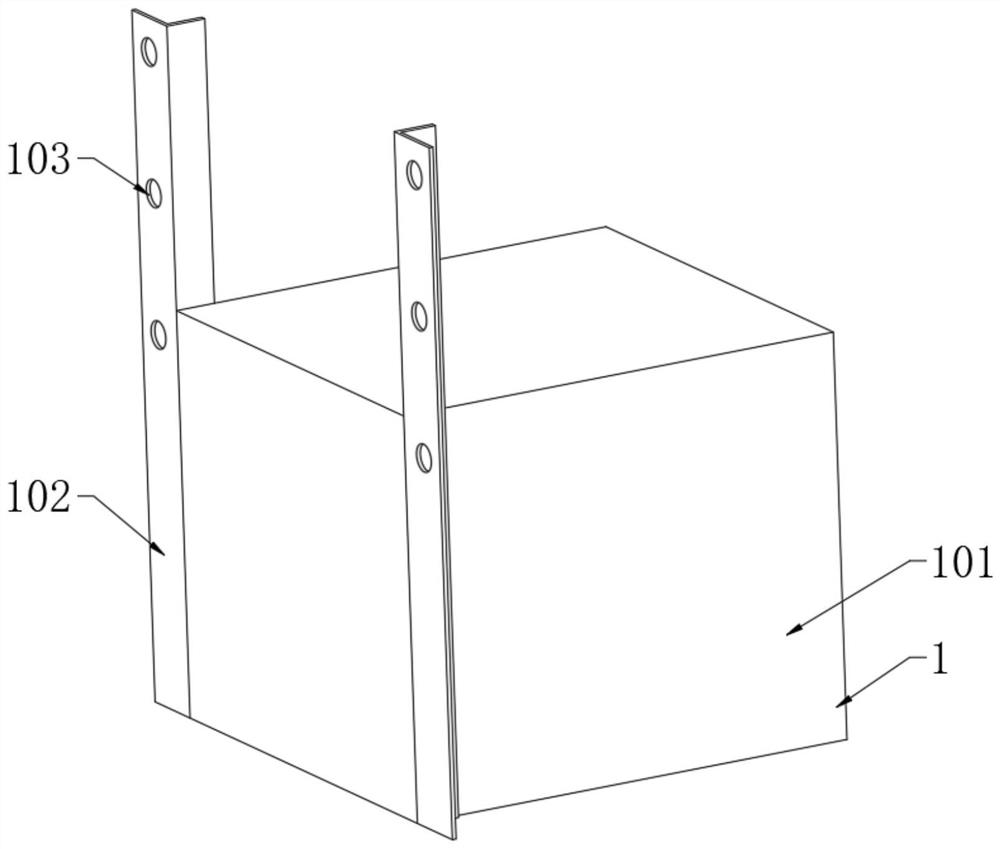

[0030] see Figure 1-7 , a high-efficiency energy-saving fan with convenient maintenance, which is composed of a support assembly 1, a transmission mechanism 3, an impeller 4, a casing 6, and an air inlet ring 8. The support assembly 1 includes a mounting base 101, and organic seats are arranged on both sides of the mounting base 101 102, three installation holes 103 are opened on the front of the base 102, the transmission mechanism 3 is screwed on the upper surface of the installation base 101 through the first screw 2, and the casing 6 is screwed on the front of the base 102 through the second screw 5, The outer diameter of the second screw 5 matches the inner diameter of the mounting hole 103 , the inside of the casing 6 is provided with the impeller 4 , and the front of the casing 6 is threaded with the air inlet ring 8 through the third screw 7 .

[0031] In this embodiment, the machine base 102 is arranged on both sides of the installation base 101, and the installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com