Textile fabric cutting device

A technology for textiles and cutting devices, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of cutting offset, unqualified quality, waste, etc. Effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

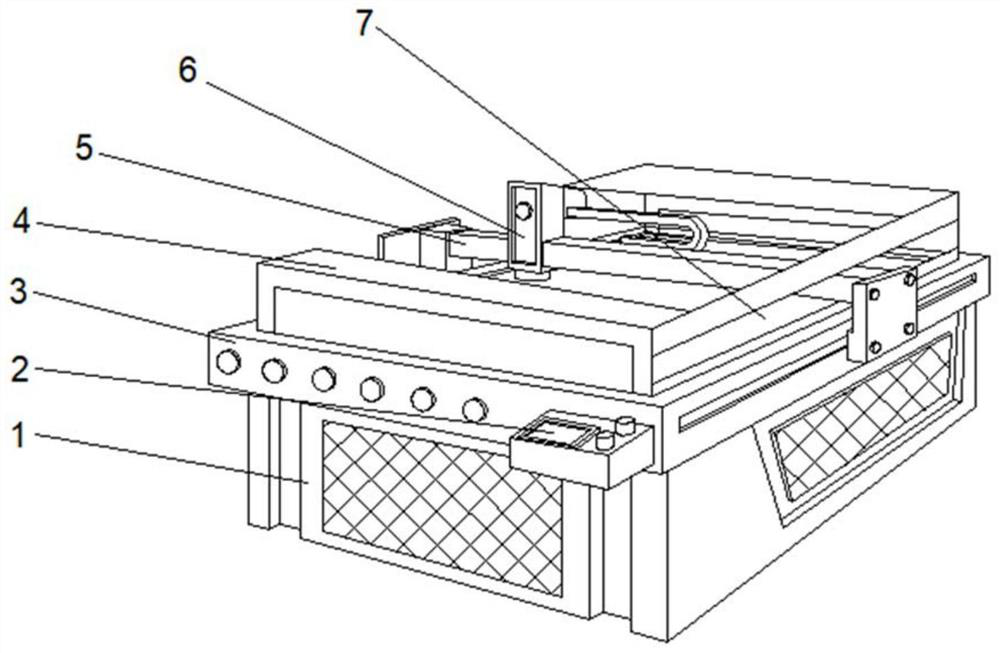

[0033] see Figure 1-2 , the present invention provides a technical solution: a textile fabric cutting device, comprising a base 1, the top of the base 1 is fixedly connected to an operating console 3, the front right side of the operating console 3 is fixedly connected to a console 2, and the top of the operating console 3 The top is fixedly connected with a protective frame 4, and the outer walls on both sides of the protective frame 4 are provided with moving grooves 7, and the middle part of the outer walls on both sides of the console 3 is provided with a driving frame 5, and the middle part of the driving frame 5 runs through the protective frame 4, and the top of the driving frame 5 A cutting device 6 is arranged on the left side of the console 3 .

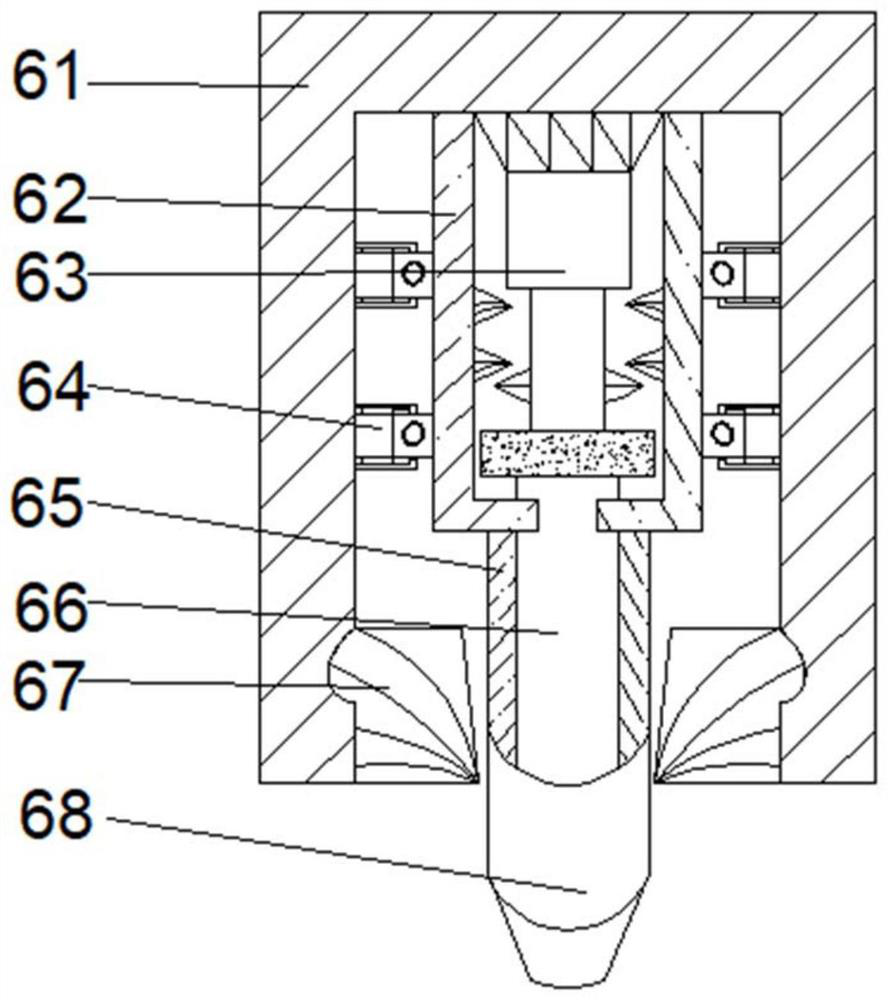

[0034] Wherein, the cutting device 6 includes a protective cover 61, the middle position of the inner cavity top of the protective cover 61 is fixedly connected with a fixed plate 62, the inner cavity top of the fixed plate...

Embodiment 2

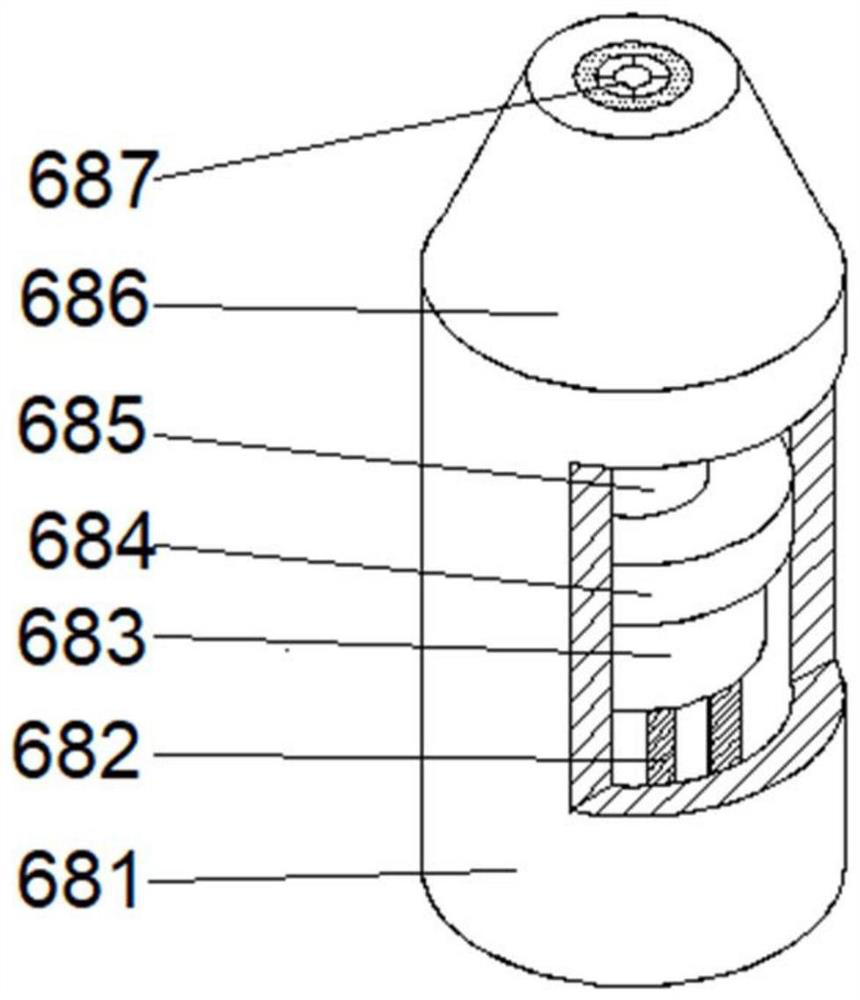

[0037] see Figure 1-3On the basis of Embodiment 1, the present invention provides a technical solution: the cutting mechanism 68 includes a main body 681, the top of the main body 681 is fixedly connected with a knife seat 686, and the middle position of the top of the base 686 is provided with a cutting knife 687, and the main body 681 A knife bar 685 is arranged at the middle position of the bottom of the inner cavity, and the top of the knife bar 685 is fixedly connected with the cutting knife 687. The middle outer surface of the knife bar 685 is provided with a fixing mechanism 684, and the bottom of the fixing mechanism 684 is fixedly connected with a sliding plate 683, and the sliding plate A rotating column 682 is provided on a side of the 683 close to the cutter bar 685 .

[0038] When in use, the cutting mechanism 68 works, and the knife bar 685 moves up and down in the main body 681, so that the sliding plate 683 and the rotating column 682 can fix the knife and the...

Embodiment 3

[0040] see Figure 1-5 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the fixing mechanism 684 includes a frame t1, the two sides of the top of the inner cavity of the frame t1 are fixedly connected with a linkage mechanism t2, and the outer walls of both sides of the linkage mechanism t2 The middle position is provided with a force block t3, and the middle position of the bottom of the force block t3 is provided with a movable ball t7. The two sides of the force block t3 away from the frame t1 are fixedly connected with a fixed rod t6, and the fixed rod t6 is far away from the force block t3. A bearing plate t4 is fixedly connected to one end of the bearing plate t4, and universal balls t5 are arranged on both sides of the bearing plate t4.

[0041] Among them, the linkage mechanism t2 includes a bottom block t21, and the middle position of the inner cavity top of the bottom block t21 is provided with a port t23, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com