A Time-Pressure Intelligent Control Method Based on Colloid Remaining Quantity

A time pressure, intelligent control technology, applied in the device, instrument, coating and other directions of coating liquid on the surface, can solve the problem of inability to achieve consistency of glue, time-consuming, etc., to achieve simple and convenient adjustment, consistent glue output , the effect of good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

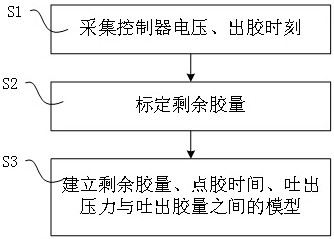

[0033] A kind of time pressure intelligent control method based on colloid remaining amount of the present invention, specifically is:

[0034] S1: Start the adjustment of the remaining glue amount, open the airway of the solenoid valve, increase the air pressure in the needle tube, and increase the voltage value of the controller accordingly, and collect the glue out time and the corresponding voltage value of the controller;

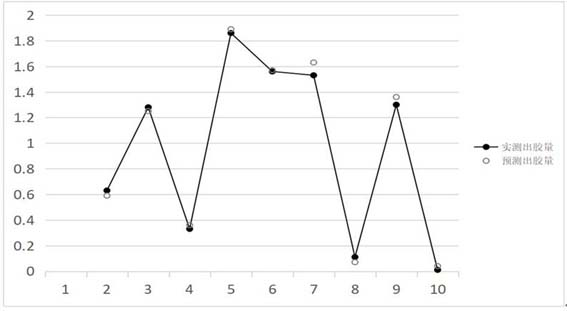

[0035] S2: According to the proportional relationship between the glue out time and the partial differential value of the voltage function and the remaining glue in the tube, the remaining glue is calibrated;

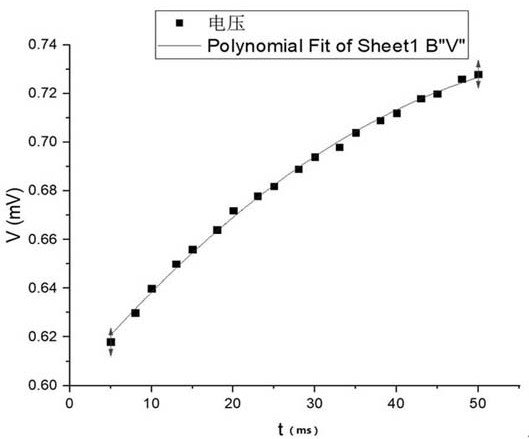

[0036] For example, set the dispensing time and dispensing pressure parameters to 50ms and 100Kpa, the dispensing pressure gradually increases, and the voltage increases accordingly, and the sample set of voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com