A lignin-based supercapacitor material with high area specific capacitance and its preparation method and application

A lignin-based, supercapacitor technology, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of high energy consumption and poor flexibility, and achieve excellent flexibility, good reversibility, and good electric double layer The effect of capacitive behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 The influence of lignin type on the area specific capacitance

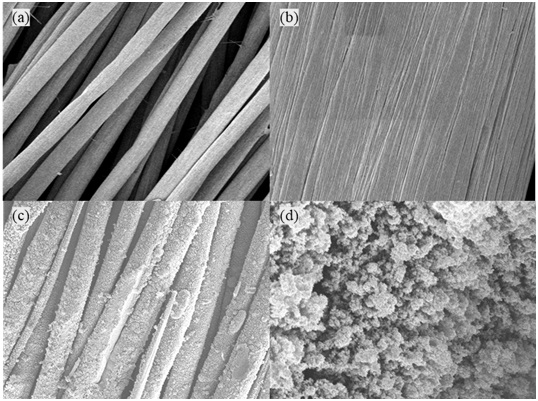

[0043] 1. Preparation of supercapacitor materials with different lignin types according to the impregnation method

[0044] (1) Dissolve 20g of hydrolyzed lignin, preoxidized lignin, and kraft lignin in 1L of 0.1M H 2 SO 4 , stirring for 12 hours, rotating speed 500rpm, room temperature, and then filtering to obtain lignin with ash removed;

[0045] (2) Place the lignin in an oven at 40°C for drying;

[0046] (3) The dried lignin is dissolved in DMF, and the soaking solution is prepared in the same ratio (lignin: DMF = 40 mg: 100 μl);

[0047] (4) Cut the carbon cloth into a size of 2.5cm×1.5cm (length×width);

[0048] (5) Draw a 2.5cm×1.5cm area on the glass slide and place the carbon cloth;

[0049] (6) Use a 100μl pipette to absorb 100μl of impregnating solution, and spread it evenly on the drawn area of the glass slide;

[0050] (7) spread the carbon cloth on the impregnating liquid...

Embodiment 2

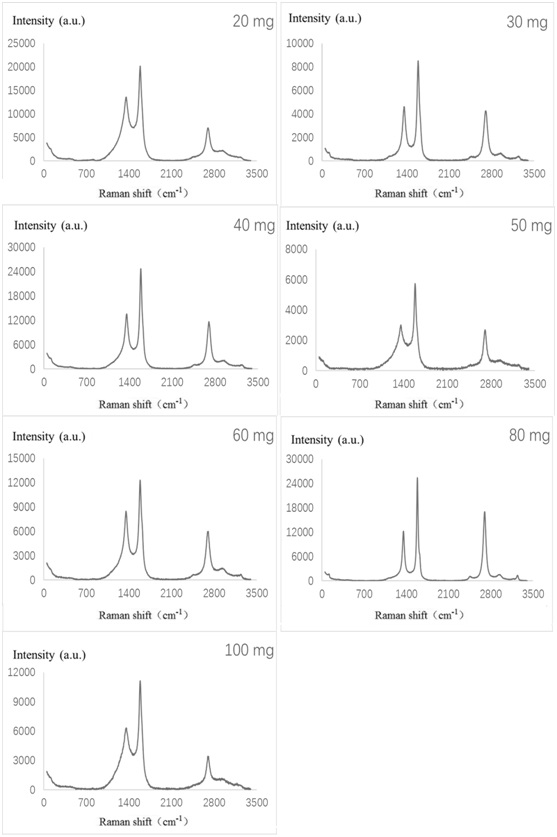

[0061] Embodiment 2 impregnation method loading lignin (under different loads)

[0062] 1. Experimental steps

[0063] (1) Dissolve 20g of hydrolyzed lignin in 1L of 0.1M H 2 SO 4 , stirring for 12 hours, rotating speed 500rpm, room temperature, and then filtering to obtain lignin with ash removed;

[0064] (2) Place the lignin in an oven at 40°C for drying;

[0065] (3) The dried lignin is dissolved in DMF, and the impregnation solutions are prepared in different proportions (lignin: DMF = 20mg: 100μl / 30mg: 100μl / 40mg: 100μl / 50mg: 100μl / 60mg: 100μl / 80mg: 100μl / 100mg: 100μl);

[0066] (4) Cut the carbon cloth into a size of 2.5cm×1.5cm (length×width);

[0067] (5) Draw a 2.5cm×1.5cm area on the glass slide and place the carbon cloth;

[0068] (6) Use a 100μl pipette to absorb 100μl of impregnating solution, and spread it evenly on the drawn area of the glass slide;

[0069] (7) spread the carbon cloth on the impregnating liquid, and allow the impregnating liquid to b...

Embodiment 3

[0076] Embodiment 3 melting method loading lignin

[0077] 1. Experimental steps

[0078] (1) Select lignin that can be melted below 180° C., and ball mill the lignin to obtain powdery lignin. The lignin used in this example is lignin extracted with an organic solvent.

[0079] (2) Add lignin at 20mg / cm 2 Spread evenly on the carbon cloth base, then place the carbon cloth coated with lignin in a heating furnace, heat it from room temperature to 180°C at a heating rate of 3°C / min, and stay at 180°C for 0.5 to 2 hours. 1 hour is used in the example. After cooling to room temperature, the molten lignin-carbon cloth composite material is obtained. At this point, the lignin has evenly melted on the carbon cloth.

[0080] (3) The composite material in step (2) is directly written by laser, and the laser used is 10.6 μm CO 2 . The printing power is 8-20W, specifically 8W, 12W, 16W, 20W. After laser direct writing, lignin can be converted into three-dimensional porous graphene ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com