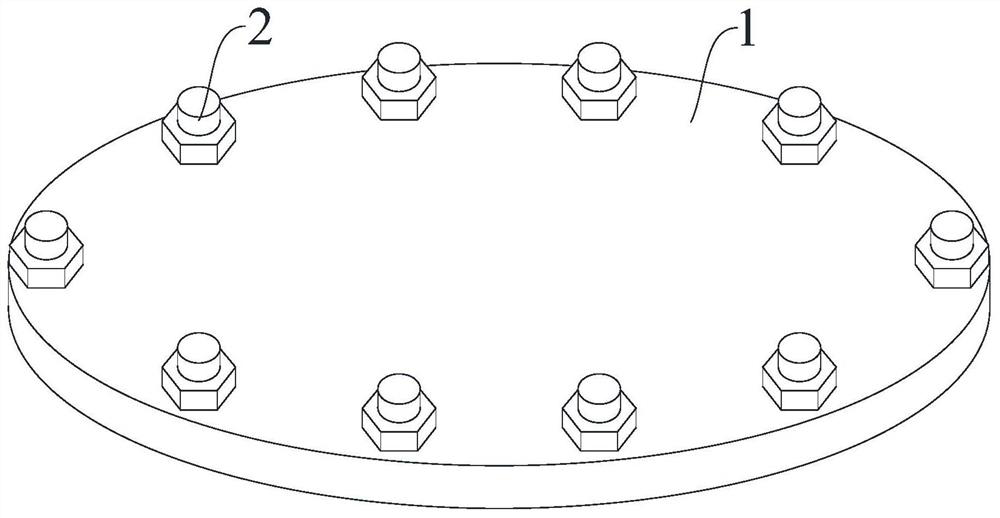

Stainless steel flange with built-in telescopic self-locking mechanism

A stainless steel, telescopic technology, applied in the direction of connecting components, mechanical equipment, fixtures, etc., can solve the problems of inability to assemble the surface locking, inability to change the structure, limited safety, etc., to improve assembly stability and firmness, reduce Cost of use and effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

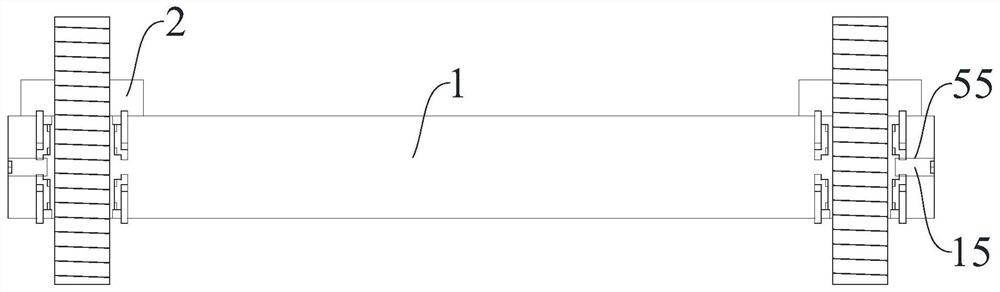

[0023] Embodiment: People control the rotation of the side adjustment rod 15 through the external hexagonal wrench to synchronously control the rotation of the upper and lower adjustment gear rings 10, so that the upper external thread adjustment ring 6 and the lower external thread adjustment ring 7 rotate synchronously, driving the internal The thread telescopic locking ring 8 is synchronously outwardly telescopic, and the operation is very simple. The lateral adjustment rod 15 can be removed, and the screwdriver with the adjustment gear directly inserted into the top is used for adjustment and control.

[0024] Further, in order to facilitate loading and unloading, the inner side wall of the upper annular adjustment groove 4 is located at the upper end opening position and the inner side wall of the lower annular adjustment groove 5 is located at the lower end opening position, and an internal thread assembly groove 13 is provided, and the thread on the outer surface of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com