Improved sleeve storage box for hot-line work robot

A technology for live work and robots, applied in manipulators, manufacturing tools, etc., can solve problems such as hidden safety hazards, high-altitude falling objects, sleeves popping out and falling, etc., to achieve the effect of simple structure, avoidance of loss, and scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

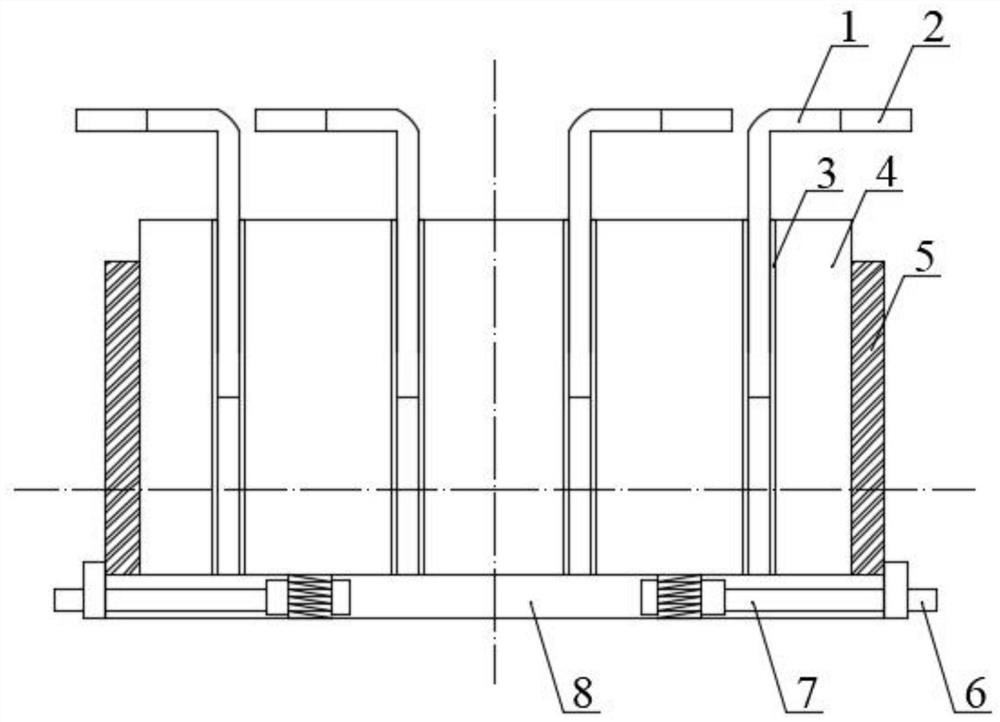

[0015] An improved sleeve storage box for a live working robot, such as figure 1 As shown, including the box body 5, an inner sleeve box 4 is detachably arranged in the box body, and at the inner bottom of the box body, the bottom 8 of the inner sleeve box is provided with a cylinder 7, and a number of chutes are provided on the inner wall of the inner sleeve box 3. There are several adjustable handles 1 slidingly arranged in the chute.

[0016] The adjustable handle is an L-shaped insulating rubber structure, including a vertical rod and an elbow, the vertical rod is detachably arranged in the chute, and the elbow is arranged on the upper end of the vertical rod.

[0017] A telescoping head 2 is de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com