Linear push type inner conical groove workpiece clamping device

A linear propulsion and tapered groove technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as cumbersome clamping operations, affecting stability, and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

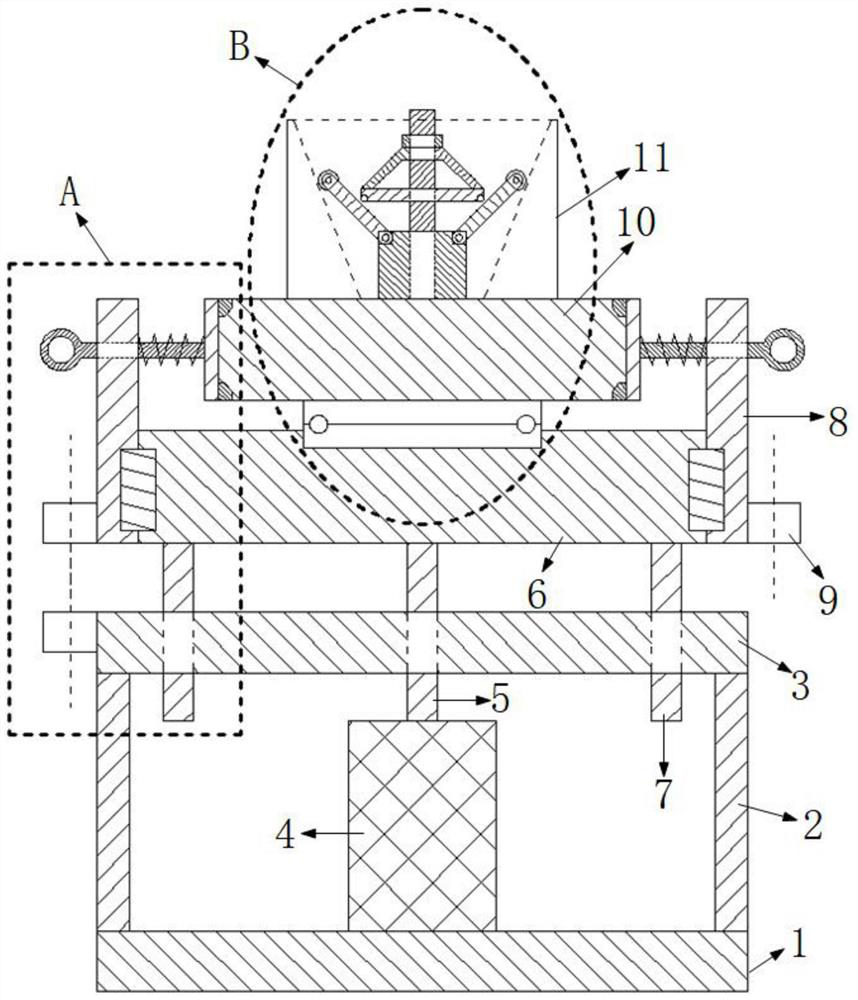

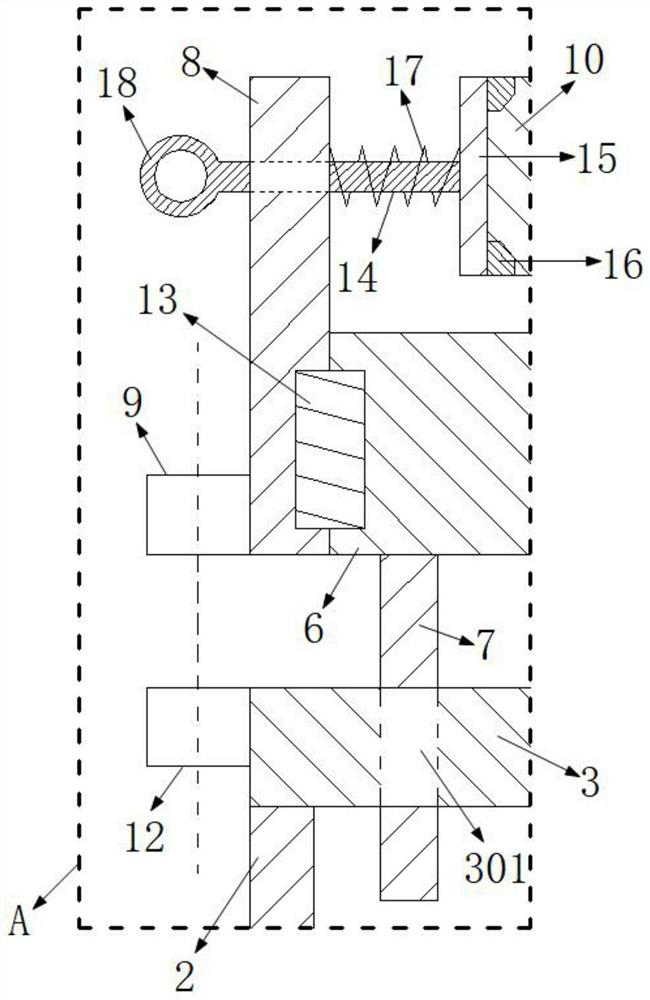

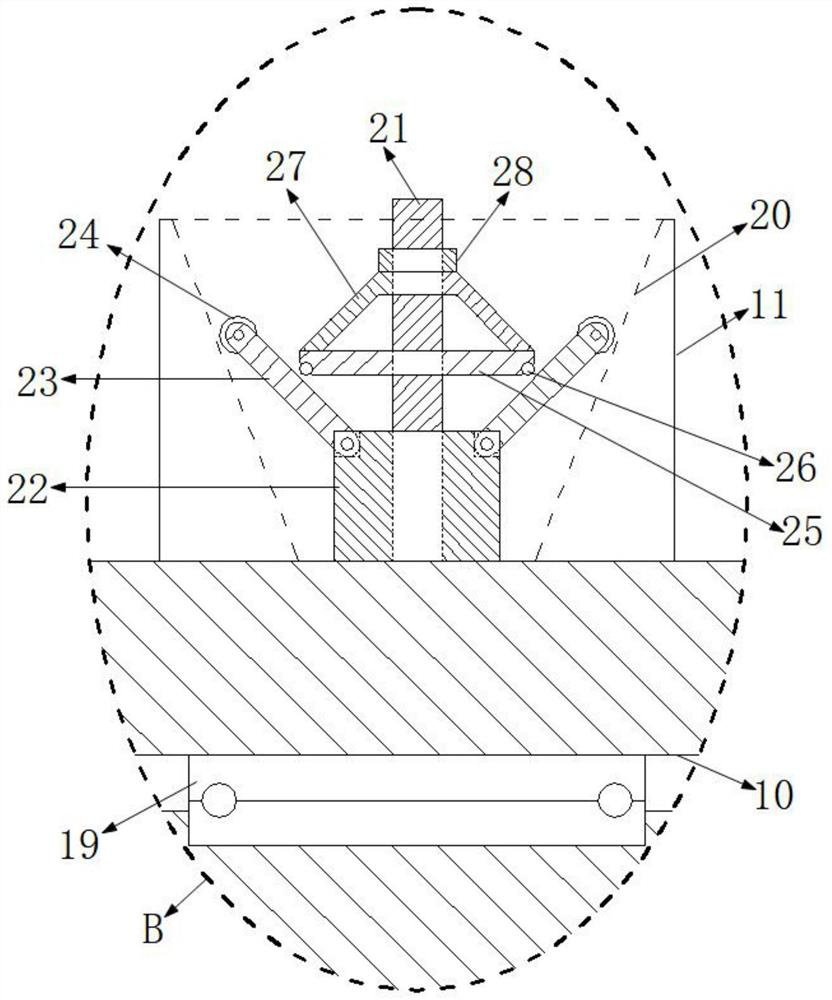

[0030] see figure 1 , figure 2 , image 3 , The invention relates to a linear propulsion type inner tapered groove workpiece clamping device.

[0031] In the structural configuration of the device of the present invention:

[0032] A lifting drive device 4 is fixedly installed at the center of the upper side of the base fixing plate 1, wherein the lifting drive device 4 adopts a servo power device or a hydraulic drive device. The lifting drive device 4 includes a lifting drive shaft 5 arranged upward; a number of base support columns 2 are fixedly installed on the edge of the upper side of the base fixing plate 1 at equal intervals, and the upper ends of the base support columns 2 are jointly connected with an upper side. The fixing plate 3 is fixedly provided with a lower positioning block 12 on the outer side of the upper fixing plate 3 .

[0033] The lifting drive shaft 5 moves through the upper fixing plate 3, and the upper fixing plate 3 is provided with a lower guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com