Lubricating system of main gear box of wind generating set and main gear box

A technology for wind turbines and main gearboxes, used in wind turbines, gear lubrication/cooling, wind power generation, etc., can solve the problems of off-line fine filter clogging, increase fan maintenance costs, high filter costs, and avoid premature clogging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

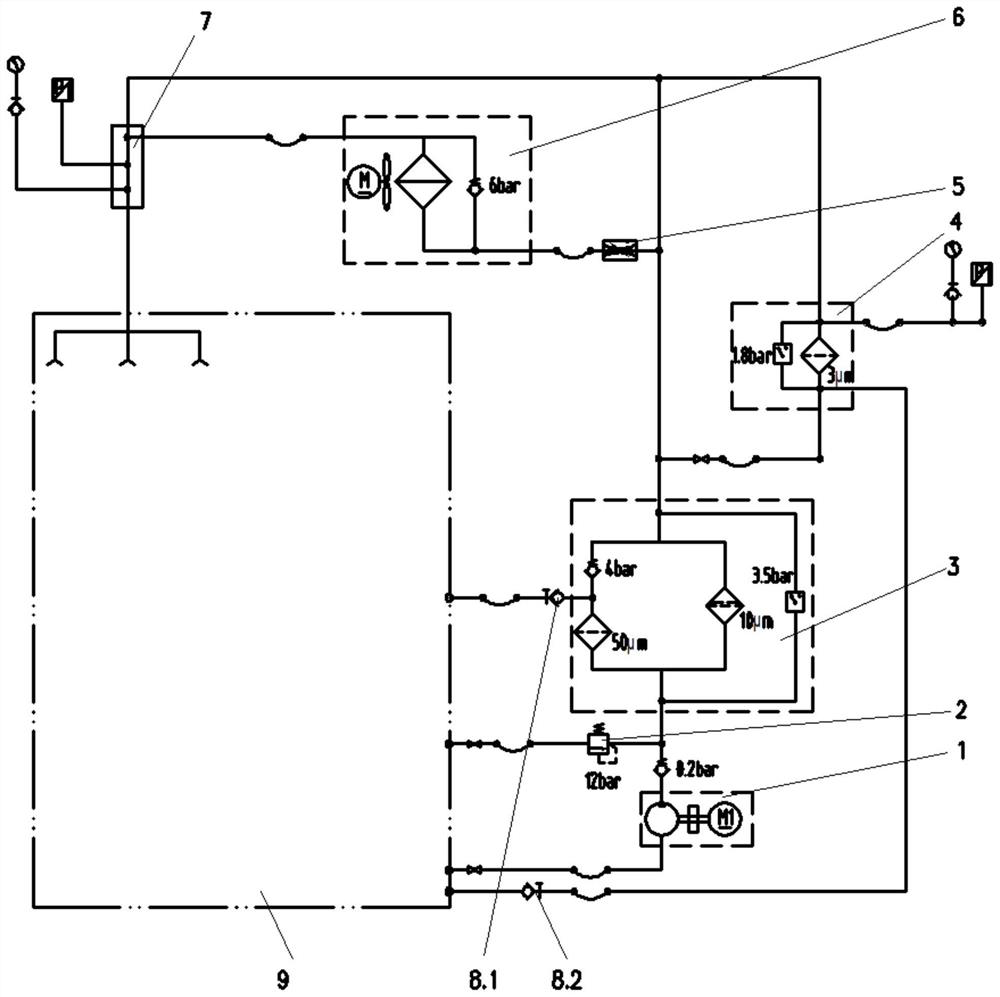

[0017] figure 1 An embodiment of the main gearbox lubrication system of the wind power generating set of the present invention is shown. The main gearbox lubrication system of the wind power generating set of this embodiment includes a circulating pump 1, an online filter 3, an off-line fine filter 4, and a temperature control valve 5. The radiator 6 and the oil distributor 7, the inlet of the circulation pump 1 is connected with the oil outlet of the main gear box 9, the outlet of the circulation pump 1 is connected with the inlet of the online filter 3, and the outlet of the online filter 3 is respectively connected with the offline The inlet of fine filter 4, temperature control valve 5 and oil distributor 7 is connected, the outlet of off-line fine filter 4 is connected with the inlet of oil distributor 7, the outlet of temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com