A suspension bridge suspension cable vibration reduction system

A vibration damping system and suspension bridge technology, applied in suspension bridges, bridges, bridge construction, etc., can solve problems such as poor vibration damping effect, achieve good vibration damping effect, reduce the impact of aesthetics, and reduce the effect of mental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

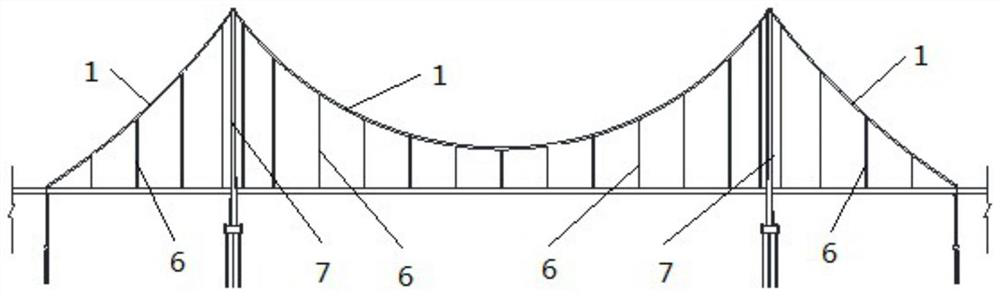

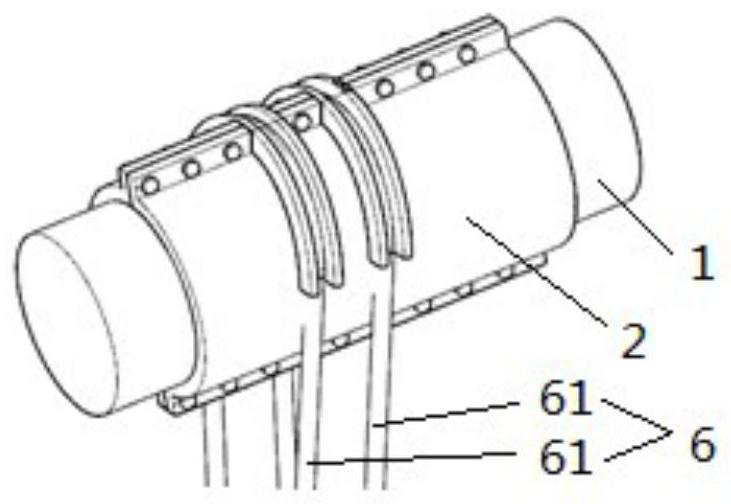

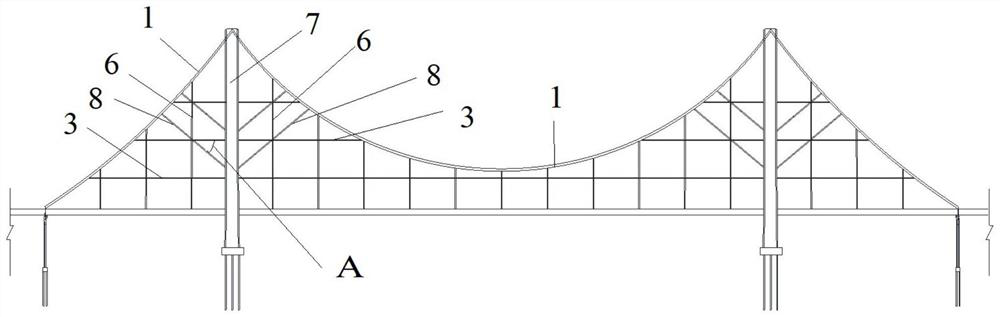

[0049] like Figure 1-9 As shown, a suspension bridge suspension cable vibration reduction system described in this embodiment includes a main cable 1, a bridge tower 7 and a suspension cable 6. The suspension cable 6 is connected to the main cable 1 through a cable clamp 2, and also includes an oblique auxiliary The cable 8 and the longitudinal auxiliary cable 3 arranged in the longitudinal direction of the bridge have an included angle A between the oblique auxiliary cable 8 and the longitudinal auxiliary cable 3, and A is (0°, 90°), wherein,

[0050] One end of the longitudinal auxiliary cable 3 is connected to the bridge tower 7 , the other end of the longitudinal auxiliary cable 3 is connected to the main cable 1 , and the longitudinal auxiliary cable 3 is connected to at least one of the suspension cables 6 connected by a rigid divider 4;

[0051] One end of the oblique auxiliary cable 8 is connected with the bridge tower 7, the other end of the oblique auxiliary cable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com