Light release film for OCA

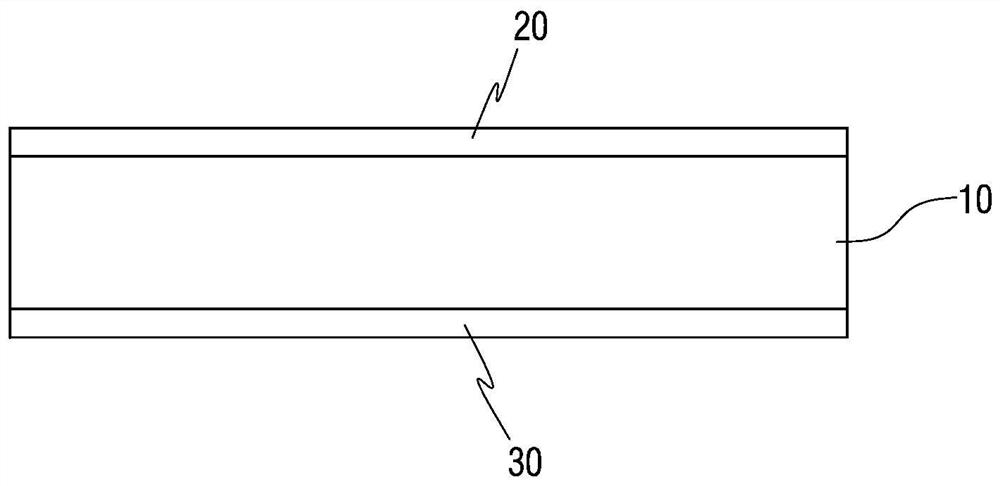

A technology of light release and release film, which is applied in the field of OCA optical adhesive, can solve the problems of unclear explanation of release force, inability to obtain OCA optical adhesive light release film, and no detailed explanation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 10 parts by weight of polyurethane resin and 10 parts by weight of ethylene-vinyl acetate copolymer into 100 parts by weight of ethyl acetate and stir for 20 to 30 minutes; then add 50 parts by weight of polydimethylsiloxane, 10 parts by weight Tetramethyltetravinylcyclotetrasiloxane and 20 parts by weight of tetrahydrofuran were stirred for 10 to 15 minutes; finally, 10 parts by weight of terpene resin tackifier was added and stirred for 10 minutes to obtain a release agent.

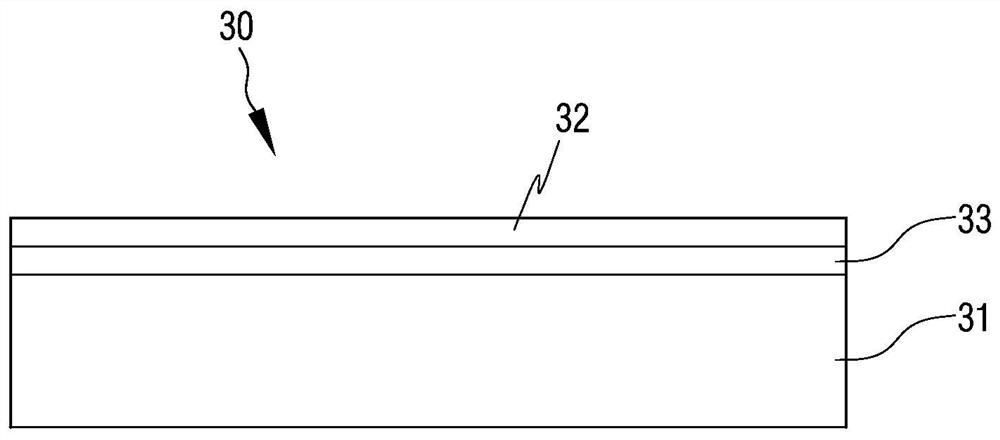

[0027] The release agent is evenly applied to the surface of the PET release film substrate 31 with a thickness of 15 μm, cured at 110° C. for 180 seconds, and the release agent layer 32 is formed after curing. The thickness of the release agent layer 32 is measured to be 2 μm.

[0028] After testing, the release agent layer 32 of this embodiment has good stability in the range of 120° C. to 250° C. without decomposition or detachment, and the release agent layer begins to decompose and detach...

Embodiment 2

[0030] Add 20 parts by weight of polyurethane resin and 20 parts by weight of ethylene-vinyl acetate copolymer into 200 parts by weight of ethyl acetate and stir for 20 to 30 minutes; then add 80 parts by weight of polydimethylsiloxane, 20 parts by weight Tetramethyltetravinylcyclotetrasiloxane and 40 parts by weight of tetrahydrofuran were stirred for 10 to 15 minutes; finally, 20 parts by weight of terpene resin tackifier was added and stirred for 10 minutes to obtain a release agent.

[0031] The release agent is evenly applied to the surface of the PET release film substrate 31 with a thickness of 30 μm, cured at 105° C. for 180 seconds, and the release agent layer 32 is formed after curing. The thickness of the release agent layer 32 is measured to be 6 μm.

[0032] After testing, the release agent layer 32 of this embodiment has good stability in the range of 120° C. to 250° C. without decomposition or detachment, and the release agent layer begins to decompose and detach w...

Embodiment 3

[0034] Add 15 parts by weight of polyurethane resin and 15 parts by weight of ethylene-vinyl acetate copolymer into 150 parts by weight of ethyl acetate and stir for 20 to 30 minutes; then add 65 parts by weight of polydimethylsiloxane, 15 parts by weight Tetramethyltetravinylcyclotetrasiloxane and 30 parts by weight of tetrahydrofuran were stirred for 10 to 15 minutes; finally, 15 parts by weight of terpene resin tackifier was added and stirred for 10 minutes to obtain a release agent.

[0035] The release agent is evenly applied to the surface of the PET release film substrate 31 with a thickness of 25 μm, cured at 110° C. for 180 seconds, and the release agent layer 32 is formed after curing. The thickness of the release agent layer 32 is measured to be 5 μm.

[0036] After testing, the release agent layer 32 of this embodiment has good stability in the range of 120° C. to 250° C. without decomposition or detachment, and the release agent layer begins to decompose and detach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com