A felt painting device and enameled wire

A felt painting device and technology for enameled wire, applied in the field of enameled wire, can solve the problems of difficulty in adapting to the wire, the distance between the first felt and the second felt cannot be adjusted, etc., and achieve the effect of high adaptability and good painting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

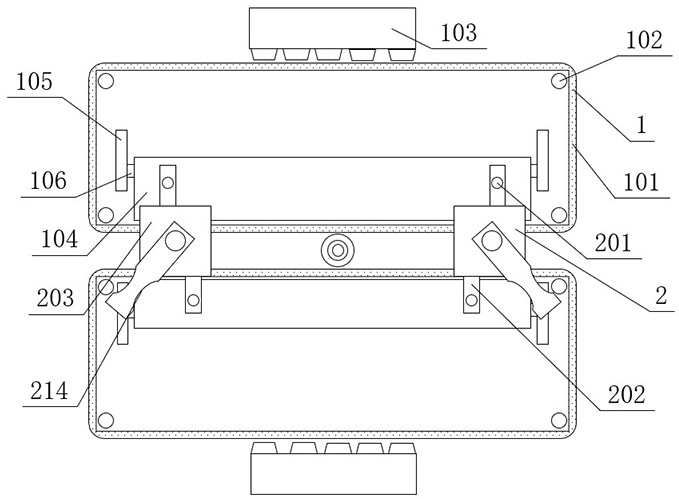

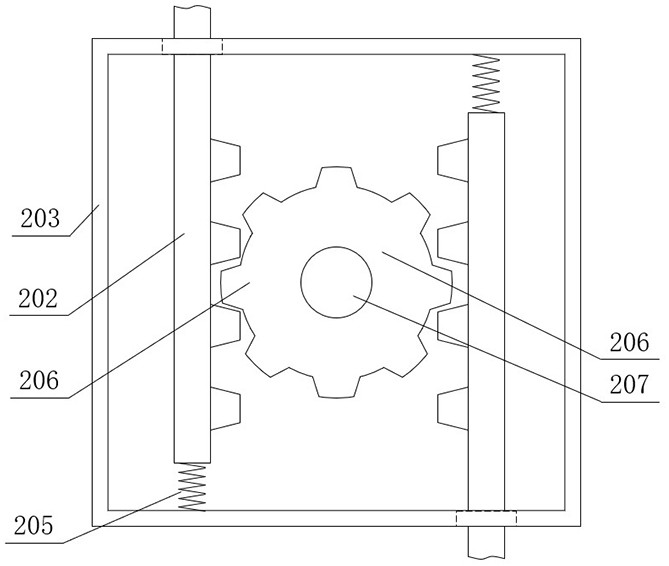

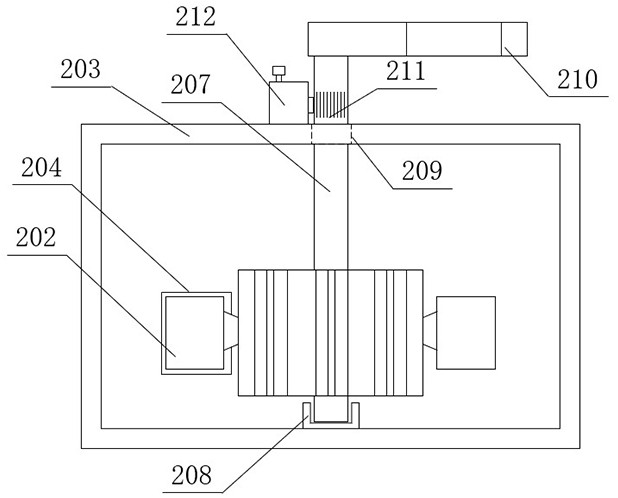

[0035] Example: as attached figure 1 , 2 , 3, 4, 5, 6 and attached Figure 7 As shown, a felt painting device includes two painting units for coating an insulating layer on the surface of the magnetic wire, and an adjusting column unit for adjusting the distance between the two painting units.

[0036] The felt painting device includes two painting units 1 for coating an insulating layer on the surface of the magnetic wire, and an adjusting column unit 2 for adjusting the distance between the two painting units 1 .

[0037] In this embodiment, the magnetic wire is a copper wire coated with one or more non-radioactive Group VIII metals, and the coated metal includes iron, cobalt, nickel, ruthenium, rhodium, palladium, , iridium, platinum.

[0038] The varnishing unit 1 includes a felt 101 for coating insulating varnish on the surface of the magnetic wire, a roller 102 arranged inside the felt 101, a paint spray cylinder 103 arranged outside the felt 101, and a roller 103 arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com