A high-performance large-area flexible transparent electrode and its preparation method and application

A transparent electrode, large-area technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of limited transfer materials, difficult demolding, expensive equipment, etc., to achieve low process costs and simple process steps. , the effect of low manufacturing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

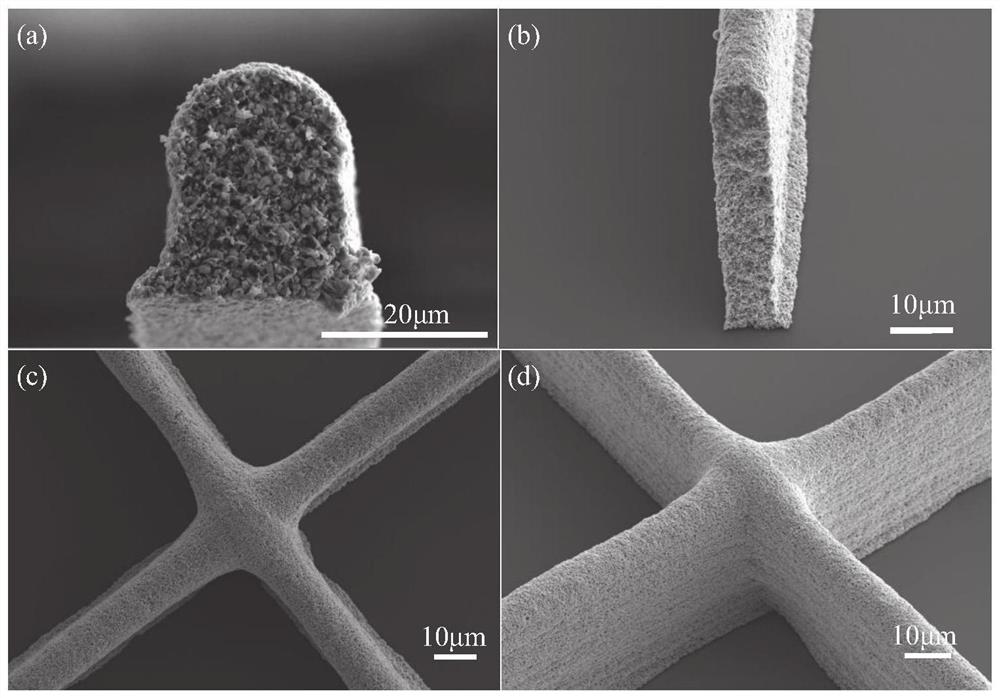

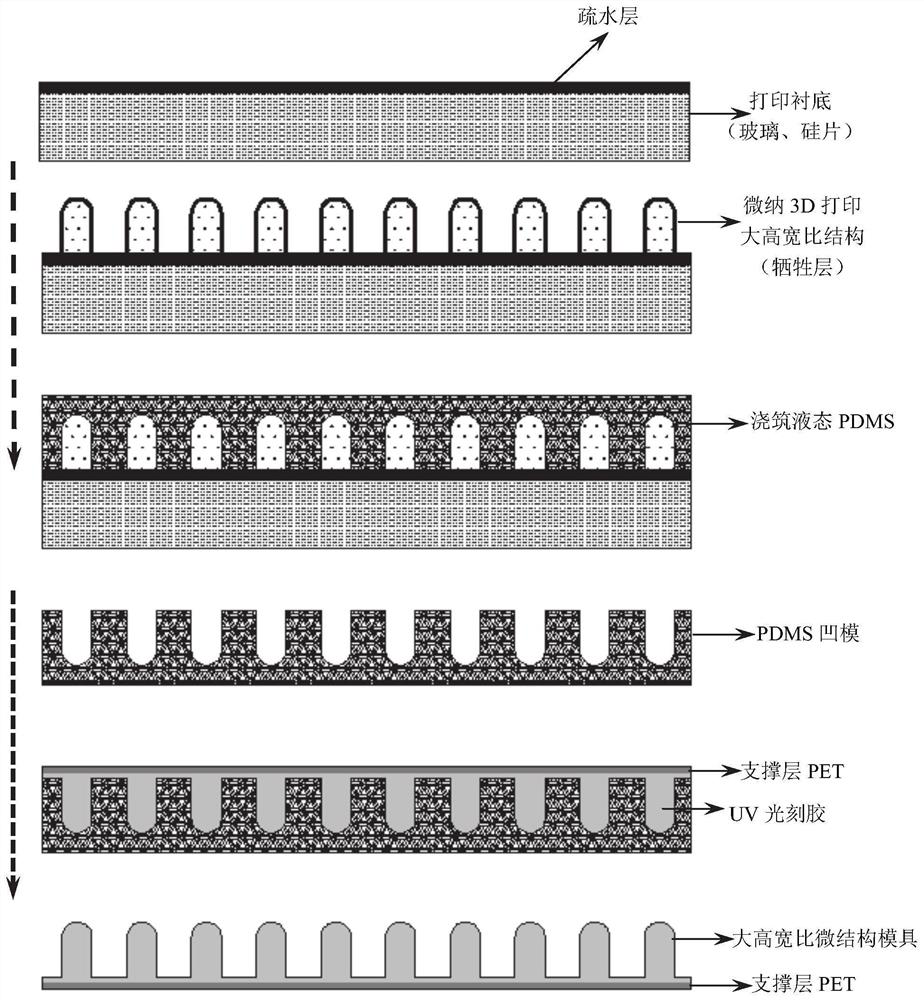

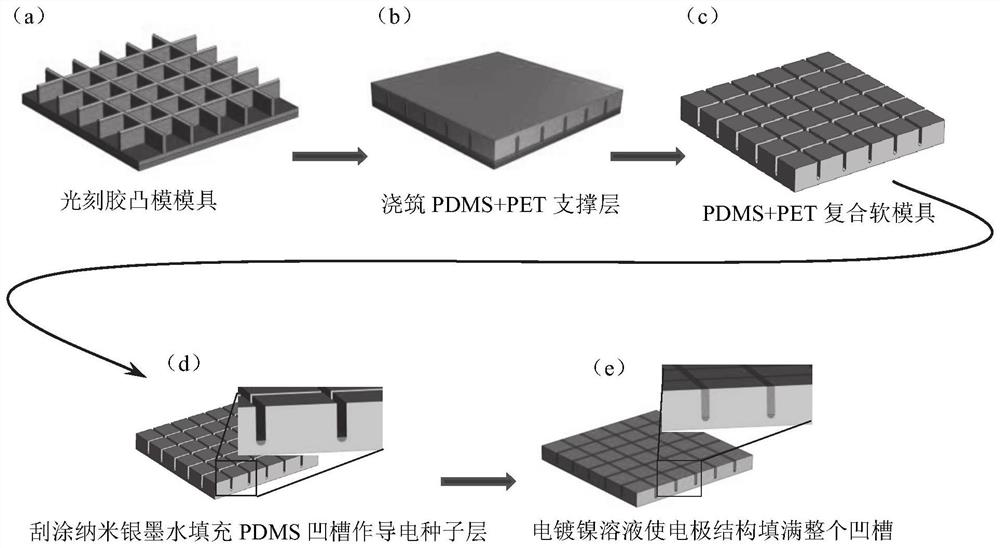

[0057] In this example, nano-conductive silver paste (NT-ST20E) is used as the printing material. First, the electric field-driven jet micro-nano 3D printing technology is used to print an ultra-fine, high-aspect-ratio wire grid structure as a sacrifice by multi-layer printing. Then, the corresponding PDMS concave mold structure is transferred on the sacrificial layer structure; then, using UV photoresist as the transfer material, the corresponding convex mold structure is transferred as the master mold , and transfer the structure on the master mold to the PDMS-PET composite mold to form a soft mold with ultra-fine and large aspect ratio; finally, the electrode structure is filled with the entire groove by electroplating process, and further conductive treatment is performed. An embedded, high-performance flexible transparent conductive film is obtained.

[0058] The process steps of manufacturing an ultra-fine, large-aspect-ratio embedded flexible transparent conductive film...

Embodiment 2

[0079] In this example, nano-conductive silver paste (NT-ST20E) is used as the printing material. First, the electric field-driven jet micro-nano 3D printing technology is used to print an ultra-fine, high-aspect-ratio grid structure as a sacrifice by multi-layer printing. Then, the corresponding PDMS concave mold structure is transferred on the sacrificial layer structure; then, using UV photoresist as the transfer material, the corresponding convex mold structure is transferred as the master mold , and transfer the structure on the master mold to the PDMS-PET composite mold to form a soft mold with ultra-fine and large aspect ratio; finally, the electrode structure is filled with the entire groove by electroplating process, and further conductive treatment is performed. An embedded, high-performance flexible transparent conductive film is obtained.

[0080] The process steps of manufacturing an ultra-fine, large-aspect-ratio embedded flexible transparent conductive film in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com