Multi-directional drying equipment for soaked wood boards during high-end equipment manufacturing

A drying equipment, multi-directional technology, applied in the direction of humidity control wood, manufacturing tools, drying solid materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

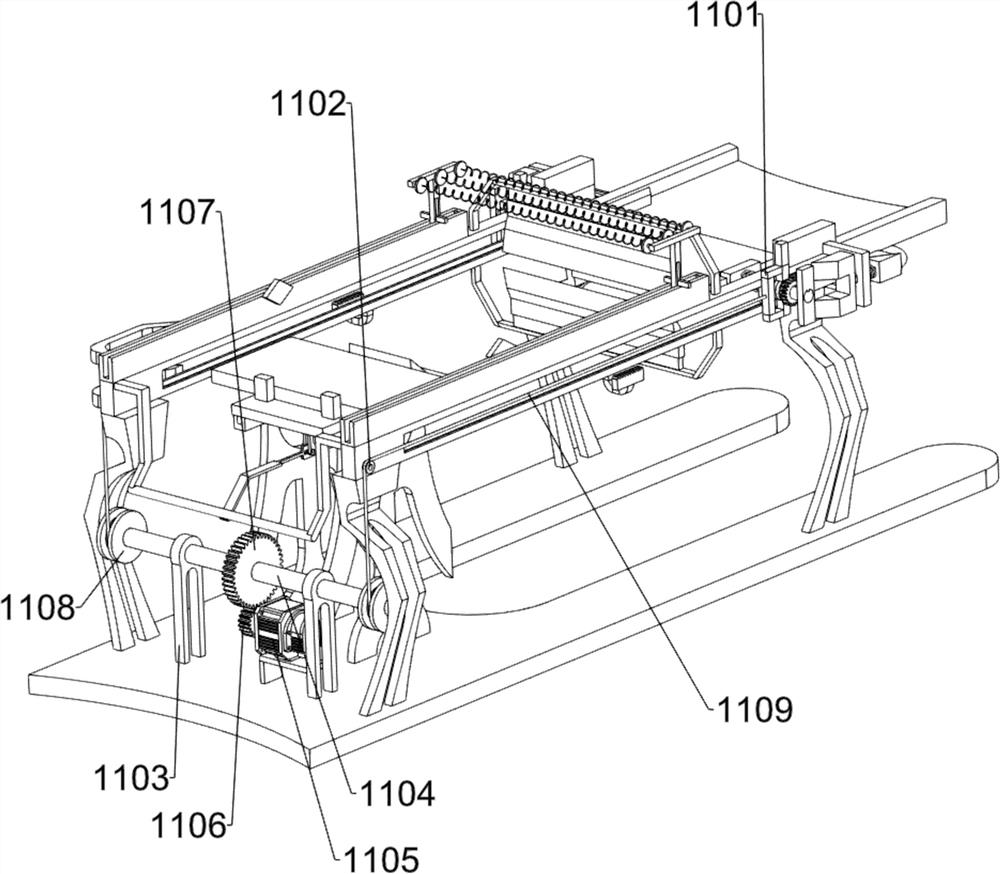

[0032] A multi-directional drying equipment for soaking wood boards during the manufacture of high-end equipment, such as figure 1 , figure 2 and image 3 As shown, it includes a bottom plate 1, a bracket 2, a chute 3, a surface dewatering mechanism 4 and a drying mechanism 5. There are brackets 2 on the four sides of the top of the bottom plate 1, and there are slides between the two brackets 2 on the same side. A surface dewatering mechanism 4 is arranged between the groove 3 and the chute 3, and a drying mechanism 5 is arranged on the chute 3.

[0033] First, people use tools to move the soaked wooden board between the surface dewatering mechanism 4, and then move the wooden board to the right, so that the surface dewatering mechanism 4 scrapes off the water on the surface of the wooden board, and then people start the drying mechanism 5 to make the drying The drying mechanism 5 dries the wooden boards moved below it, and people can take away the wooden boards after the ...

Embodiment 2

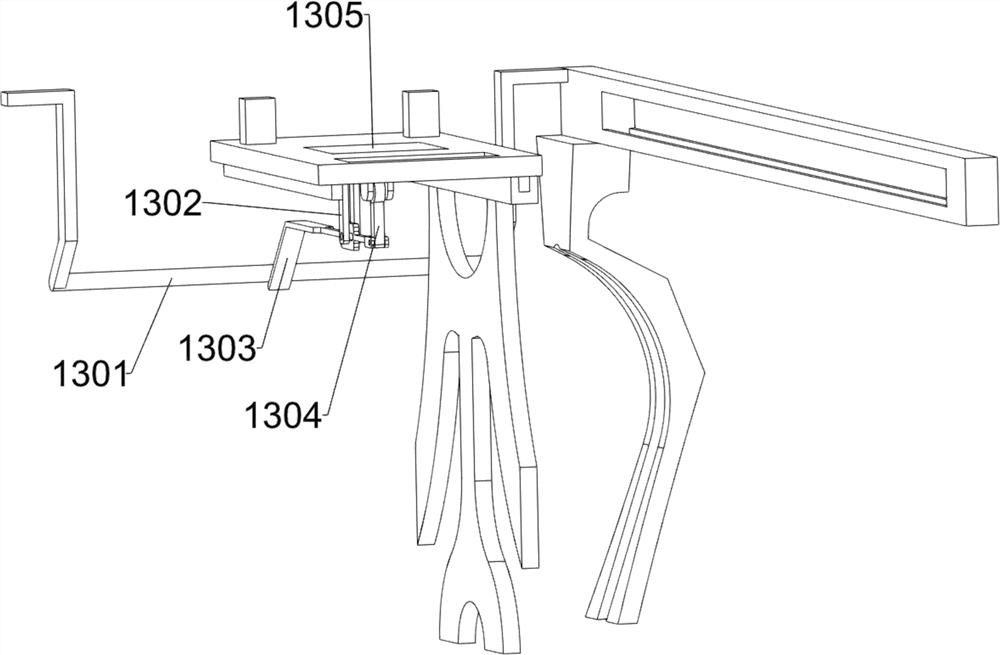

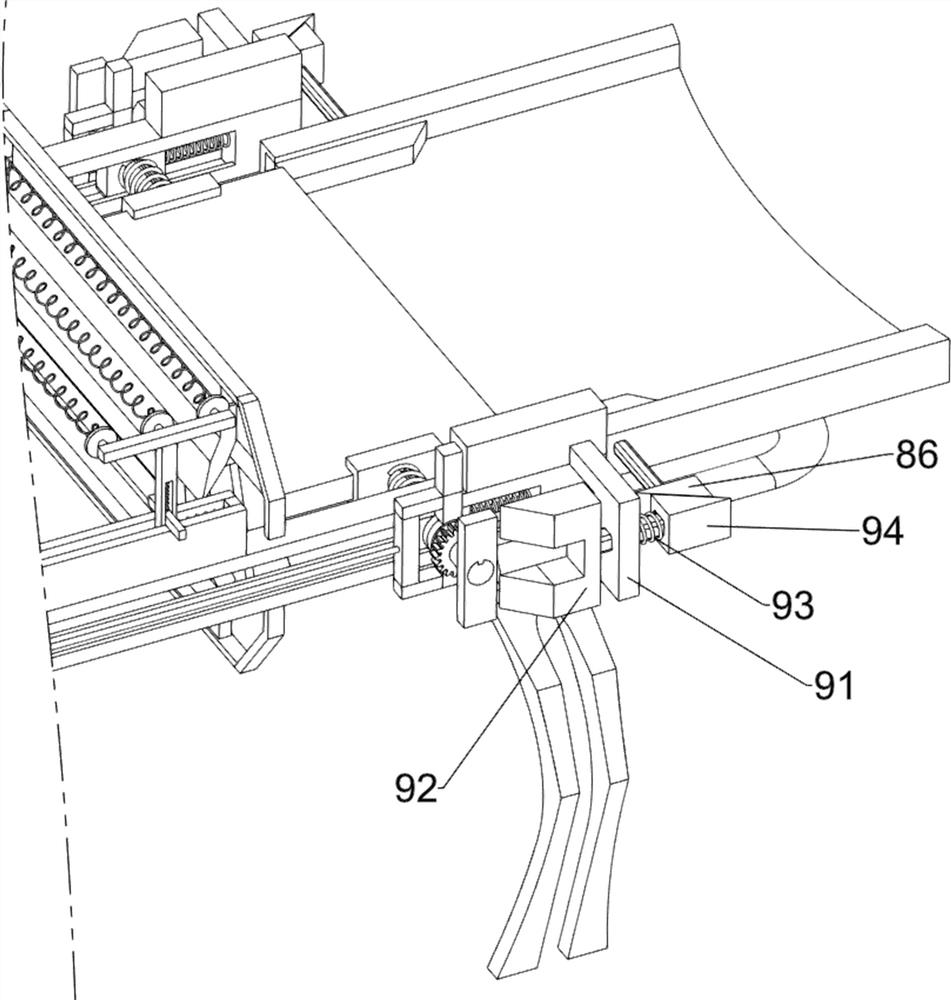

[0038] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes a feed guide mechanism 8, and the feed guide mechanism 8 includes a second connecting rod 81, a guide plate 82, a fourth spring 83, a trapezoidal block 84, a third connecting rod 85 and a first wedge block 86, left The two brackets 2 on the side are provided with a second connecting rod 81, and a guide plate 82 is arranged between the second connecting rods 81. The front and rear sides of the guide plate 82 are symmetrically provided with a fourth spring 83, and the guide plate 82 slides symmetrically. The formula is provided with a trapezoidal block 84, the trapezoidal block 84 is connected with the fourth spring 83, the third connecting rod 85 is provided on the trapezoidal block 84, the third connecting rod 85 slides on the guide plate 82, and the end of the third connecting rod 85 Each is provided with a first wedge b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com