Mortar pretreatment system and method

A pretreatment and mortar technology, applied in construction, building structure, etc., can solve the problems of cracking, building wall durability and impact resistance loss, cracked wall, etc., to improve the filling firmness and ensure the safety of connection sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

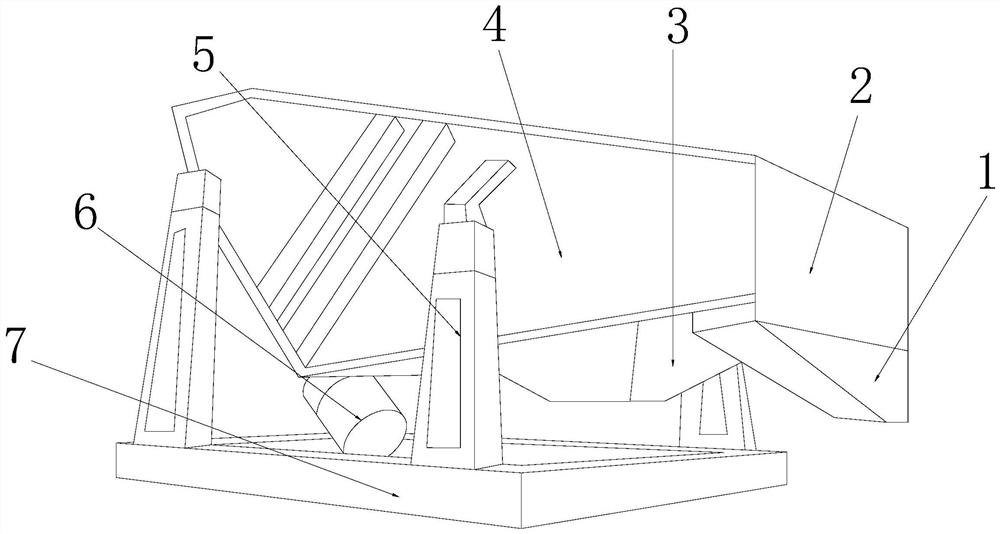

[0034] see Figure 1-Figure 7 , The present invention provides a mortar pretreatment system and method, the structure of which includes: a discharge chute 1, a collection box 2, a mortar lining ladder groove 3, a long bucket groove 4, a support column plate 5, a motor 6, and a base plate 7. The mortar lining ladder groove 3 is nested in the lower right corner of the tipping bucket long groove 4 and communicates with each other, the collection box 2 is inserted in the right side of the tipping bucket long groove 4, and the discharge chute 1 is nested in the Under the bottom of the collection box 2 and on the same vertical plane, the long bucket slot 4 is fastened with the support column plate 5, the motor 6 is inserted in the lower left corner of the long slot 4 of the dump bucket, and the support column plate 5 are provided with four and are vertically welded on the four corners of the base bottom plate 7, the motor 6 is installed on the upper left corner of the base bottom pl...

Embodiment 2

[0041] see Figure 1-Figure 7 , the present invention provides a kind of mortar pretreatment system and method, other respects are identical with embodiment 1, and difference is:

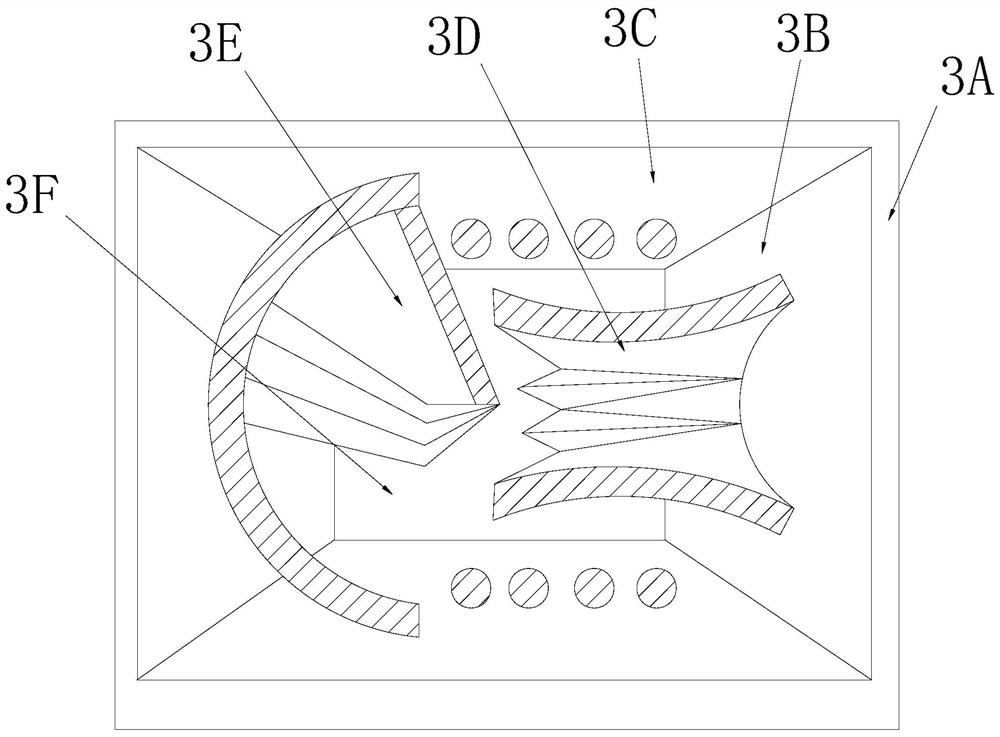

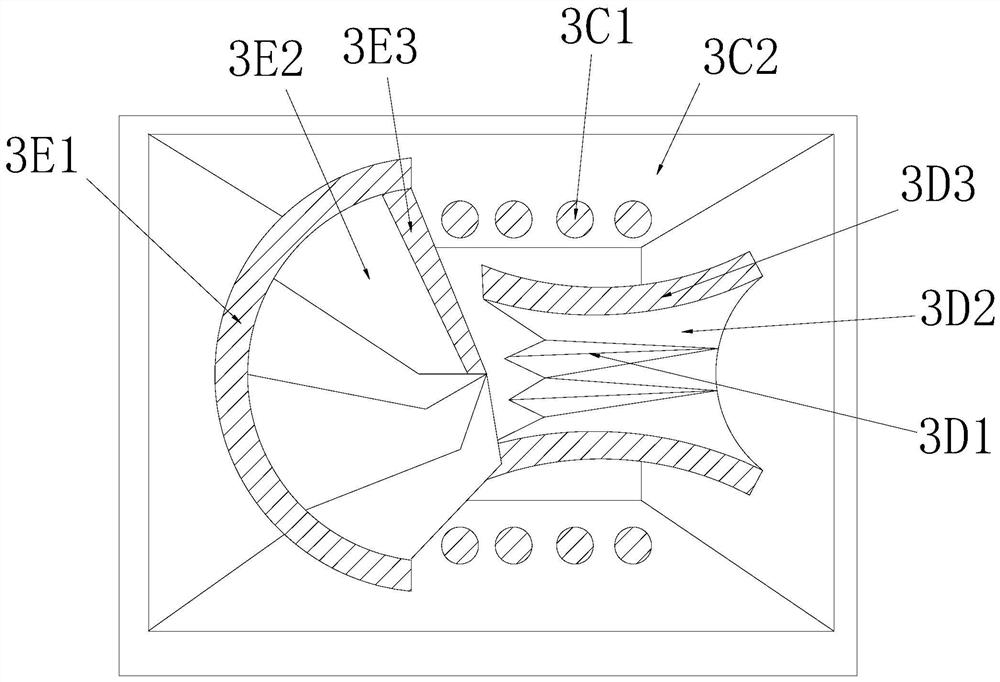

[0042] see image 3 , the narrow filter hole 3C is composed of a filter hole 3C1 and a narrow trapezoidal wing 3C2, the filter hole 3C1 is installed inside the narrow trapezoidal wing 3C2 and is on the same slope, the filter hole 3C1 and The narrow trapezoidal wing plate 3C2 adopts interference fit, and eight narrow trapezoidal wing plates 3C2 are arranged in a line on both sides through the slurry filter hole 3C1 to form the sedimentation and filtering operation effect of soaking the mortar at the bottom edge of the plate.

[0043] see Figure 4 The slurry filter hole 3C1 is composed of an inclined filter screen 3C11, a baffle frame plate 3C12, a sealing frame ring 3C13, and a slot sleeve 3C14, and the inclined filter screen 3C11 and the baffle frame plate 3C12 are inserted into the sealing frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com