Changeable combined patch pocket template capable of meeting different appearances

A variable, patch pocket technology, applied in the field of garment stitching, to achieve the effect of reducing operation steps, reducing board changing time, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

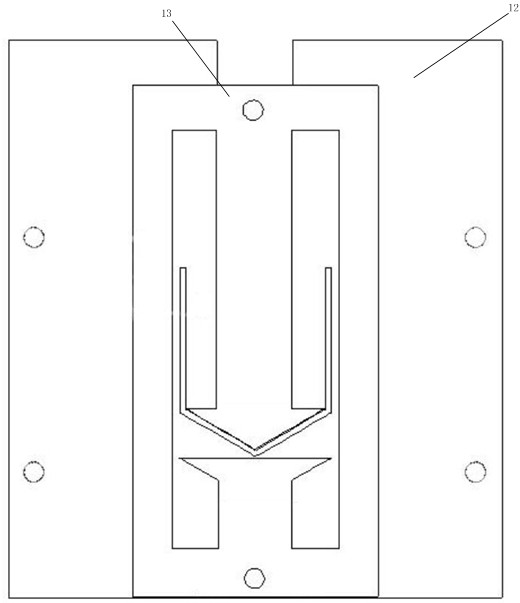

[0040] refer to Figure 1-Figure 6 As shown, a variable combination patch pocket template that satisfies different shapes, the variable combination patch pocket template includes a left upper layer 1, a right upper layer 2, a lower layer 3 and a pressing plate 4, and the left upper layer 1 and right upper Laminate 2 is respectively connected with described lower deck 3 through 22 and hinge 23, and described fastening member 22 is respectively arranged at the intersection of described left upper deck 1, right upper deck 2, lower deck 3, and described fastening member 22 Can be split.

[0041] The upper left board 1 and the upper right board 2 both include a first upper board 5 and a second upper board 6, and the lower parts of the first upper board 5 and the second upper board 6 are provided with an upper board sewing through groove 7, and the second upper board The top of an upper deck 5 is provided with a hollow mouth 8 having the same shape as the sewing groove 7 of the upp...

Embodiment 2

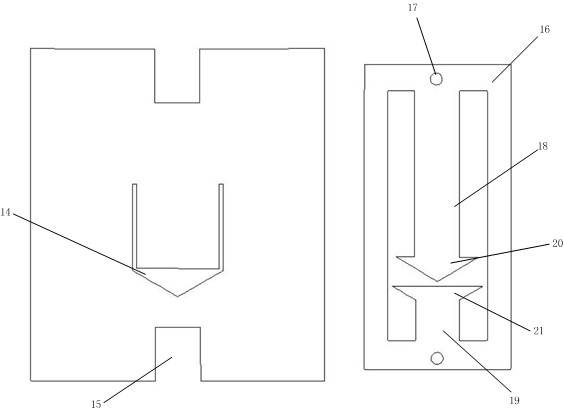

[0051] refer to Figure 1-Figure 6 As shown, a variable combination patch pocket template that satisfies different shapes, the variable combination patch pocket template includes a left upper layer 1, a right upper layer 2, a lower layer 3 and a pressing plate 4, and the left upper layer 1 and right upper Laminate 2 is respectively connected with described lower deck 3 through 22 and hinge 23, and described fastening member 22 is respectively arranged at the intersection of described left upper deck 1, right upper deck 2, lower deck 3, and described fastening member 22 Can be split.

[0052] The upper left board 1 and the upper right board 2 both include a first upper board 5 and a second upper board 6, and the lower parts of the first upper board 5 and the second upper board 6 are provided with an upper board sewing through groove 7, and the second upper board The top of an upper deck 5 is provided with a hollow mouth 8 having the same shape as the sewing groove 7 of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com