High-voltage wiring harness system for new energy automobile

A technology for new energy vehicles and high-voltage wiring harnesses, applied in vehicle parts, electrical components, circuits or fluid pipelines, etc., can solve problems such as trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

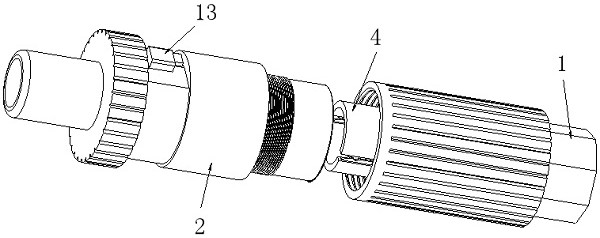

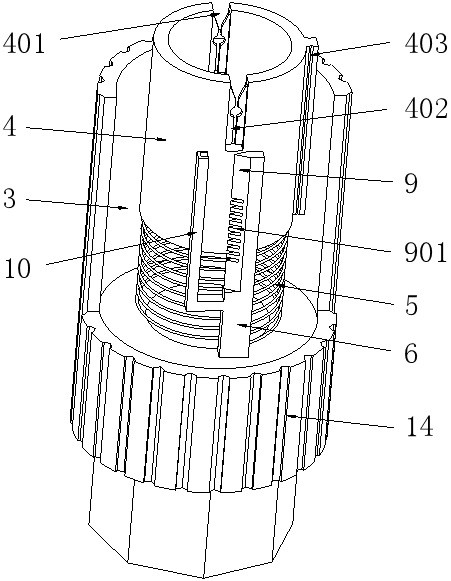

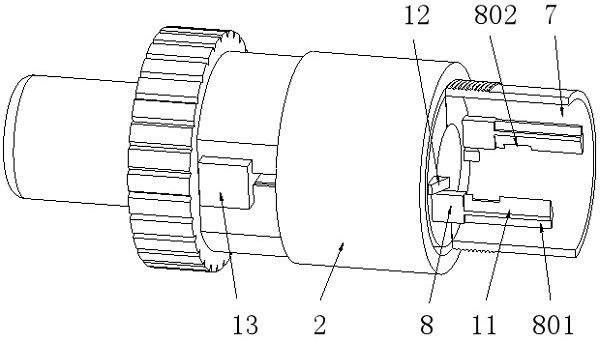

[0025] see Figure 1-3 , a high-voltage wire harness system for new energy vehicles, including a first joint 1 and a second joint 2, both of which are hollow structures, and one end of the first joint 1 is provided with a first fixing groove 3, And the first fixing groove 3 is provided with a wire harness fixing seat 4, and the wire harness fixing seat 4 is elastically connected with the first fixing groove 3 through an elastic connector 5, and the outside of the wire harness fixing seat 4 is provided with a first knife rod 6, and a second joint One end of 2 is provided with a second fixing groove 7, and a second knife rod 8 is arranged in the second fixing groove 7. The wire harness holder 4 is cylindrical, and one end of the wire harness holder 4 is provided with a plurality of notches 401 , and two splints 402 are arranged symmetrically inside the notch 401 , and the outer side of the splint 402 is provided with an arc-shaped limiting groove.

[0026] The push-in connector...

Embodiment 2

[0029] Please further combine on the basis of Example 1 Figure 4 , the difference between embodiment 2 and embodiment 1 is that: the wire harness holder 4 is cylindrical, and one end of the wire harness holder 4 is provided with several notches 401, and two splints 402 are symmetrically provided in the notches 401, and The outer side of the splint 402 is provided with several conical protrusions. In Embodiment 1, only one arc-shaped limiting groove is provided on the outer side of the splint 402, which makes the fixing position of the wire harness fixed when the wire harness is fixed. Yes, in this technical solution, several tapered protrusions are arranged on the splint 402, and the wire harness can be clamped between any two tapered protrusions when it is fixed, which is more flexible.

Embodiment 3

[0031] Please further combine on the basis of Example 1 figure 2 and image 3, this embodiment is a further improvement on Embodiment 1, the bottom end of the first knife bar 6 is fixedly connected with the first joint 1, and the position and number of the first knife bar 6 correspond to the notch 401 one by one, the first knife bar The front end of the rod 6 is provided with a first cutter 9 , and one side of the first cutter rod 6 is provided with a limiting rod 10 . The limiting rod 10 is L-shaped, and one end of the limiting rod 10 is fixedly connected with the first knife rod 6 , and the other end of the limiting rod 10 is provided with a slot. One end of the second knife bar 8 is fixedly connected with the second joint 2, and the other end of the second knife bar 8 is provided with a second cutting knife 11, and the back of the second knife bar 8 is provided with a limiting rib 801, and the second cutting knife The tail of the knife 11 is provided with a limit groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com