A Longmen Machining Center with Resonant Noise Reduction

A machining center, resonant technology, used in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of weak connection stability, inconvenient connection, labor-consuming, etc., to reduce manual operations, facilitate connection, Anti-shake effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

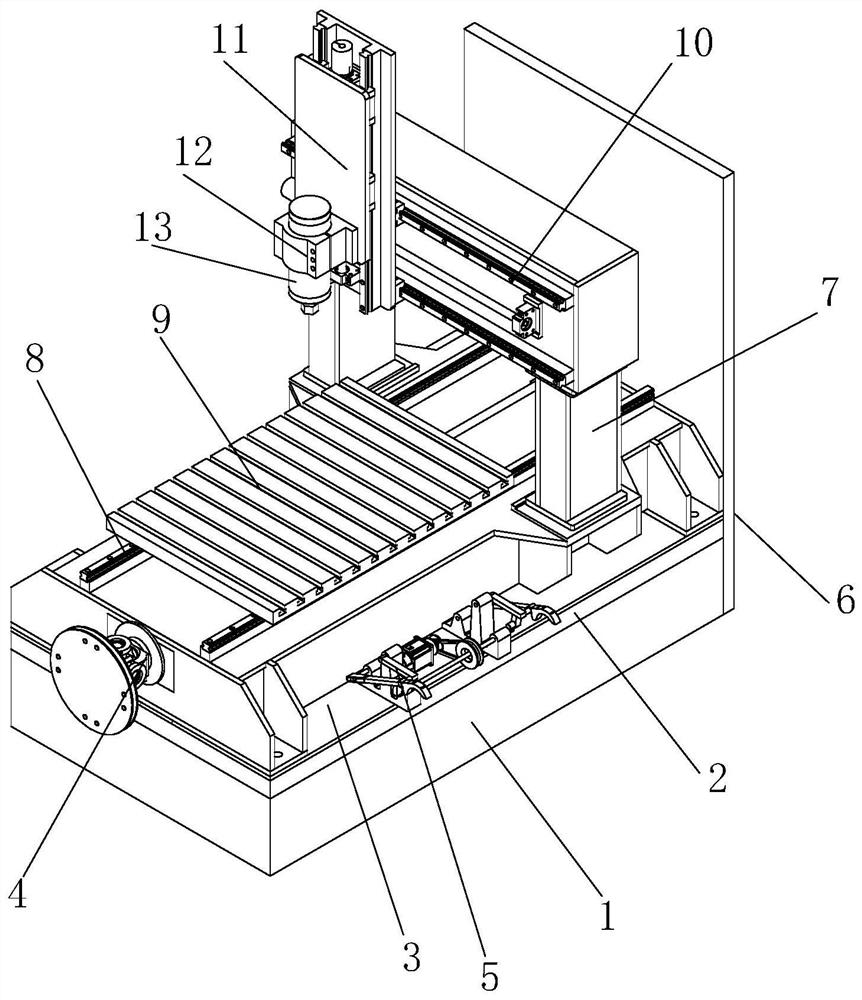

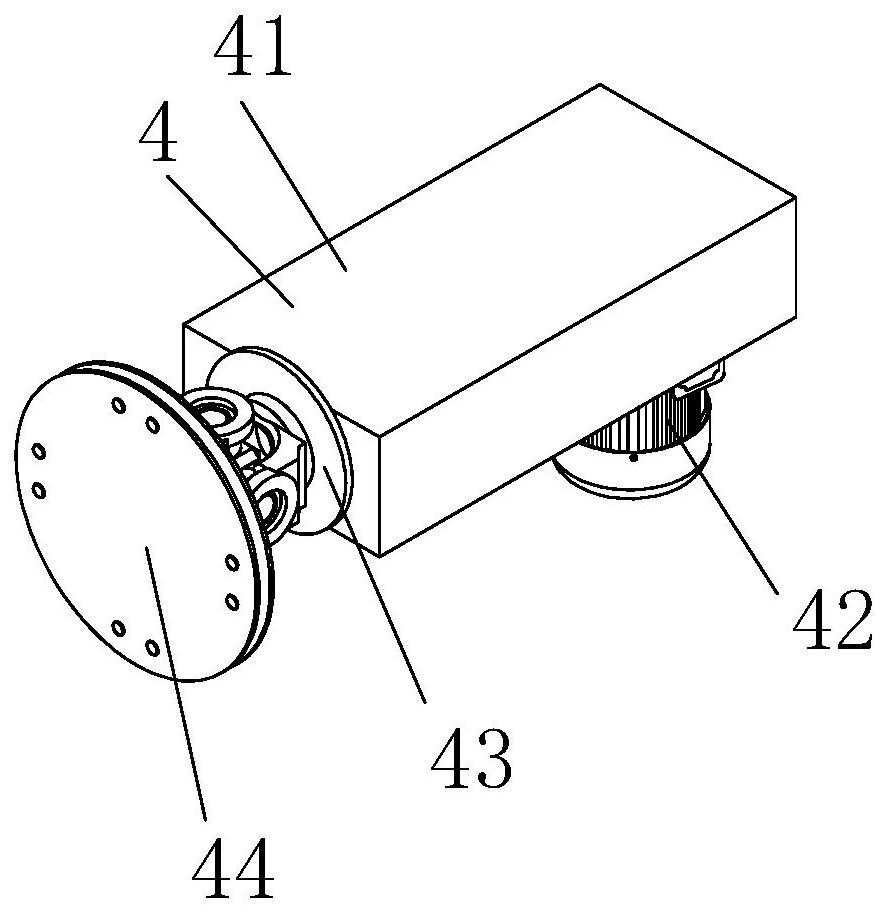

[0031] see figure 1 , the present invention provides a resonant noise reduction gantry machining center through improvement, including a base 1, a resonant noise reduction device main body 2 is fixed on the top of the base 1, a support 3 is installed on the top of the resonant noise reduction device main body 2, and the base 1 The back plate 6 is fixed on the back, the gantry frame 7 is vertically fixed on the top rear end of the support 3, the main body 8 of the Y-axis slide table is installed in the middle part of the top end of the support 3, and the middle part of the top end of the main body 8 of the Y-axis slide table connects with the workbench 9, and the gantry An X-axis sliding table main body 10 is arranged on the front end surface of the frame 7, and a Z-axis sliding table main body 11 is arranged on the left end of the front end surface of the X-axis sliding table main body 10. A tool 13 is embedded in the inner middle, an auxiliary device 4 is embedded in the fron...

Embodiment 2

[0039] The present invention provides a resonant noise-reducing gantry machining center through improvement. Guide sleeves are fixed at the left and right ends of the front end of the box body 411, and the guide rod 417 runs through the guide sleeve, which facilitates stable guidance for the movement of the guide rod 417; A layer of silica gel is bonded to the four ends of the linkage part 433 and the first steering part 432 and the second steering part 434, which has high friction, strong stability after adjustment, and is not easy to shift; the front end of the pressure plate 444 is bonded with a layer of rubber Layer, convenient to provide stable adhesion, good fixation; the left, middle and right positions of the upper end of the base 561 are convex, and the raised position in the middle of the base 561 is greater than the height of the raised ends at both ends, so that the swinging member 564 can be stabilized transmission.

[0040] In this patent: the main body 8 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com