Rotary manual peeling machine for bamboo shoot processing

A rotary type, peeling machine technology, applied in the field of bamboo shoot processing, can solve the problems of cumbersome procedures, consuming human resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

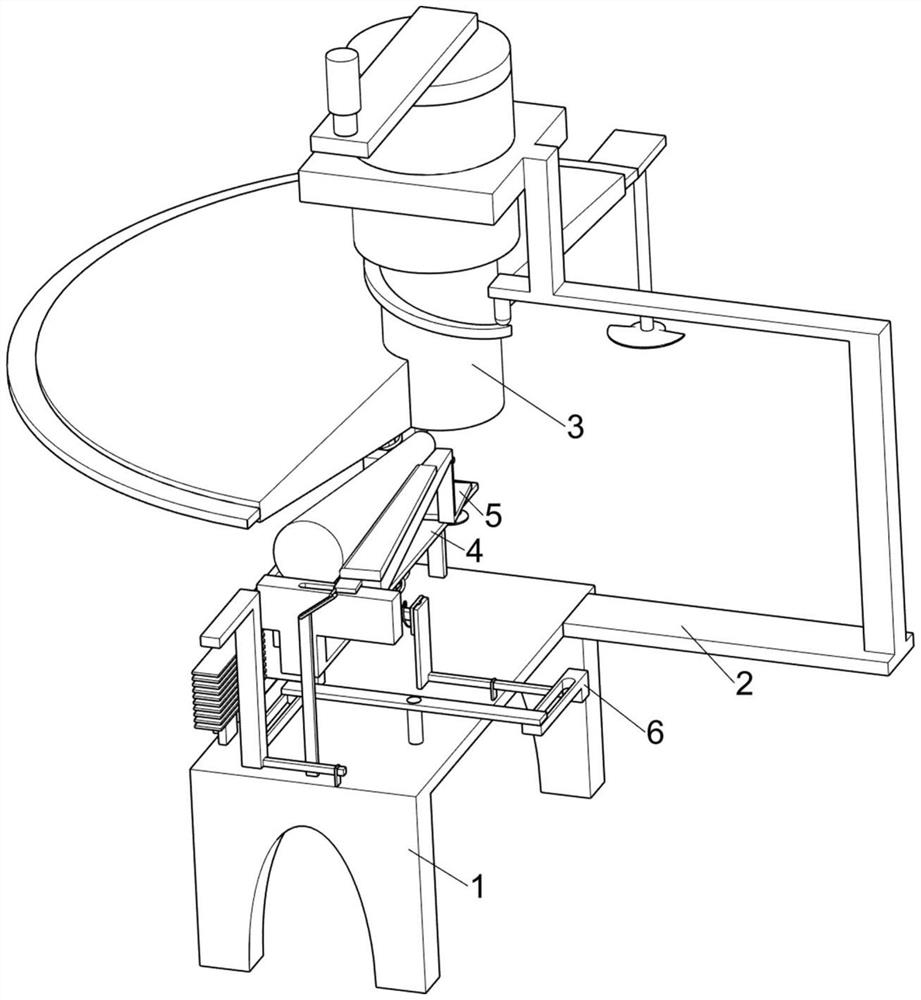

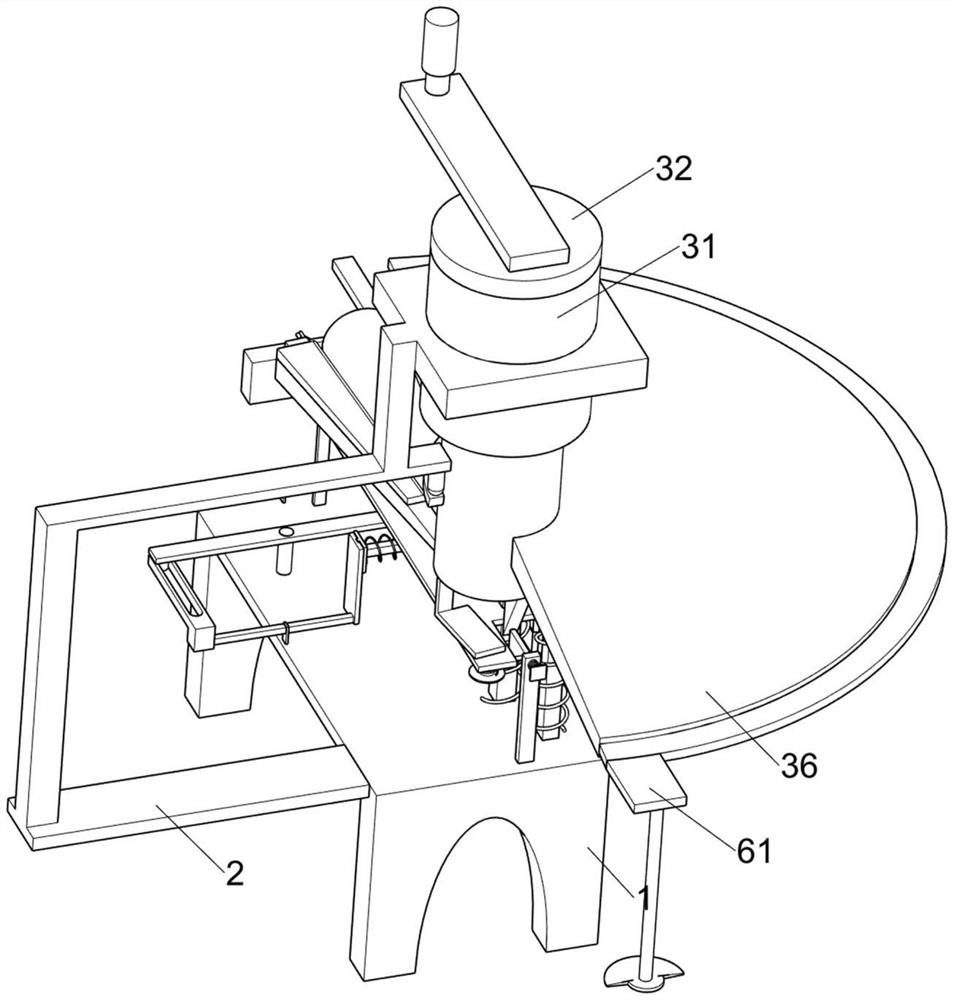

[0025] Embodiment: a kind of bamboo shoot processing is used rotary type manual peeling machine, as Figure 1-10 As shown, it includes an installation base 1, a first support frame 2, a rubbing assembly 3, a pressing assembly 4, a limit assembly 5 and a classification assembly 6. The installation base 1 is fixedly installed with a first support frame 2, and the first support The rack 2 is rotatably connected with a rubbing assembly 3, the rubbing assembly 3 is used to fully peel off the bamboo shoots, and the pressing assembly 4 is arranged on the installation base 1, and the limiting assembly 5 for limiting the bamboo shoots is rotatable. Connected to the pressing component 4, the installation base 1 is provided with a sorting component 6 for sorting the bamboo shoots.

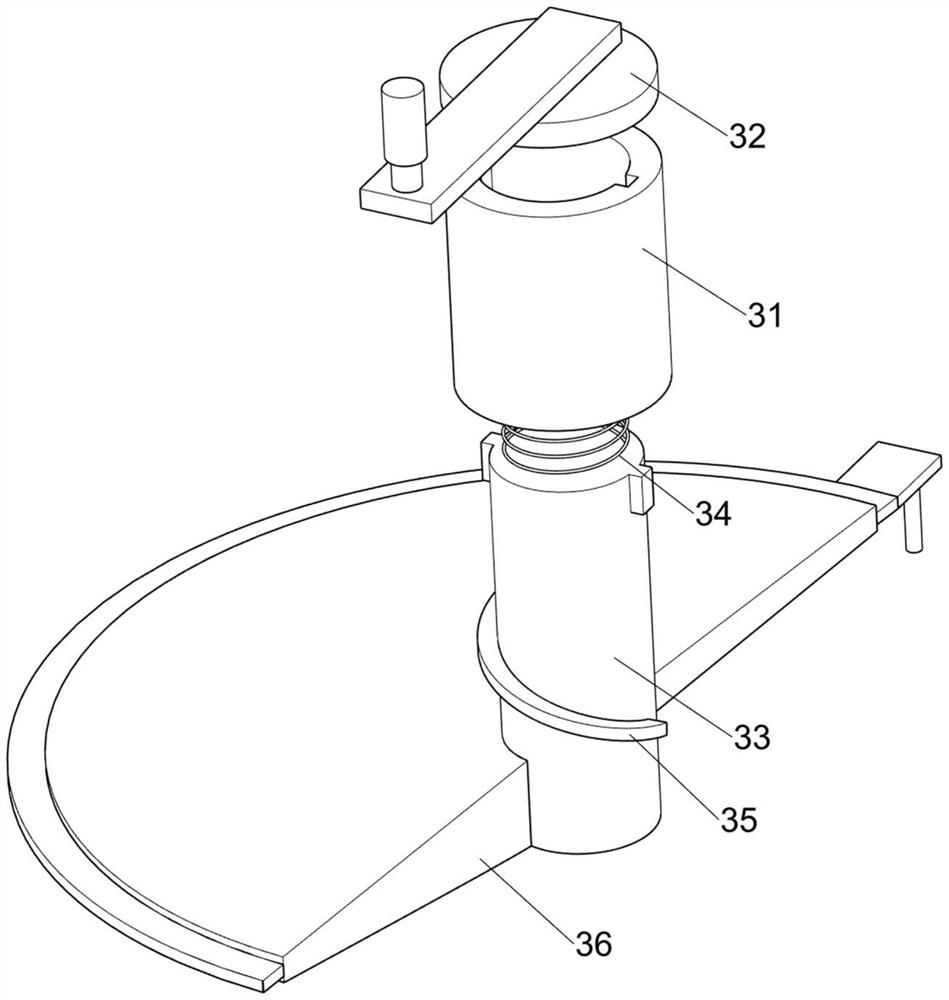

[0026] Rubbing assembly 3 includes sliding sleeve 31, turret 32, support shaft 33, the first spring 34, guide bar 35, rubbing disc 36, support column 37 and cutting knife 38, and the rotation type is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com