Camellia seed shelling device based on rotary extrusion

A technology of camellia seeds and extruding rods, which is applied in the fields of shelling, pod removal, fat oil/fat production, etc. It can solve the problems of easily damaged tea seeds and incomplete shelling of camellia seeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

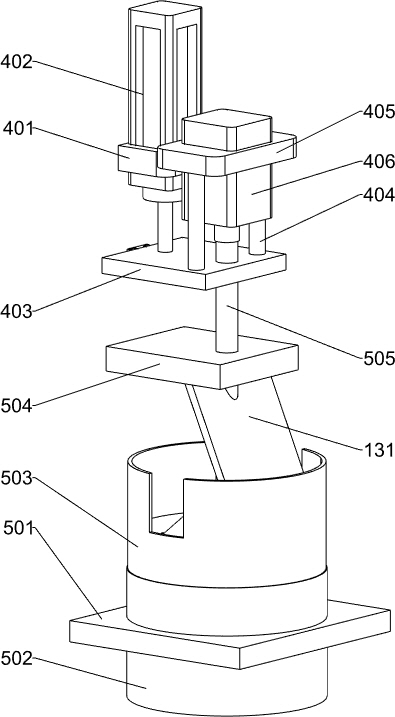

[0037] A kind of camellia seed shelling device based on rotary extrusion, such as figure 1 As shown, it includes a bottom frame 1, a support plate 2, a fixed frame 3, a driving mechanism 4 and a shell removal mechanism 5. The left part of the bottom frame 1 is equipped with a support plate 2, and the right side wall of the support plate 2 is connected with the bottom frame 1. Two fixed mounts 3 are fixedly connected between the right parts, and a driving mechanism 4 is installed on the right side wall of the support plate 2 between the front and rear two fixed mounts 3, and a drive mechanism 4 is installed on the right side wall of the support plate 2 on the lower side of the driving mechanism 4. The shell removal mechanism 5 is connected with the driving mechanism 4 .

[0038] When the camellia seeds need to be shelled, the user pours an appropriate amount of camellia seeds into the shelling mechanism 5, and then the user starts the driving mechanism 4 to make the shelling me...

Embodiment 2

[0040] On the basis of Example 1, such as figure 2 As shown, the driving mechanism 4 includes a first mounting frame 401, a telescopic cylinder 402, a sliding plate 403, a pole 404, a second mounting frame 405 and a reduction motor 406, and the first mounting frame 401 is fixed on the right side of the support plate 2 On the upper part of the wall, the telescopic cylinder 402 is arranged in the first mounting frame 401, and a sliding plate 403 is slidably arranged on the right side wall of the support plate 2 on the lower side of the first mounting frame 401, and the lower end of the telescopic cylinder 402 telescopic rod and the sliding plate 403 The top is fixedly connected, and the right side of the top of the sliding plate 403 is fixedly connected with two struts 404. The two struts 404 are front and rear symmetrical. A deceleration motor 406 is arranged inside the 405 .

[0041]When the camellia seeds need to be shelled, the user starts the deceleration motor 406 to wor...

Embodiment 3

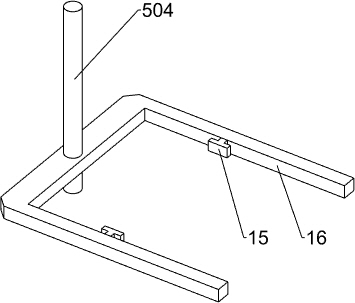

[0045] On the basis of Example 2, such as Figure 4-6 Shown, also comprise connecting plate 6, support 7, connecting frame 8, holding box 9, fixed block 10, the first rotating rod 11, the first spring 12, the first swing plate 13 and blanking plate 131, support plate 2 Connecting plates 6 are arranged on the front and rear side walls of the lower part, brackets 7 are fixed between the right parts of the two front and rear connecting plates 6, and four connecting frames 8 are fixedly connected to the top of the brackets 7, and the four connecting frames 8 Filling box 9 is installed between, and the top of support 7 of both sides of filling box 9 front and back all is equipped with fixed block 10, and the first rotary rod 11 is installed in the rotating type between front and rear two fixed blocks 10, and the first rotary rod 11 wears Over the material box 9, a first spring 12 is fixedly connected between the fixed block 10 and the material box 9, the first spring 12 is wound on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com