Vibrating type textile material flushing device

A technology for textile materials and flushing devices, applied in the field of textiles, can solve problems such as poor cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

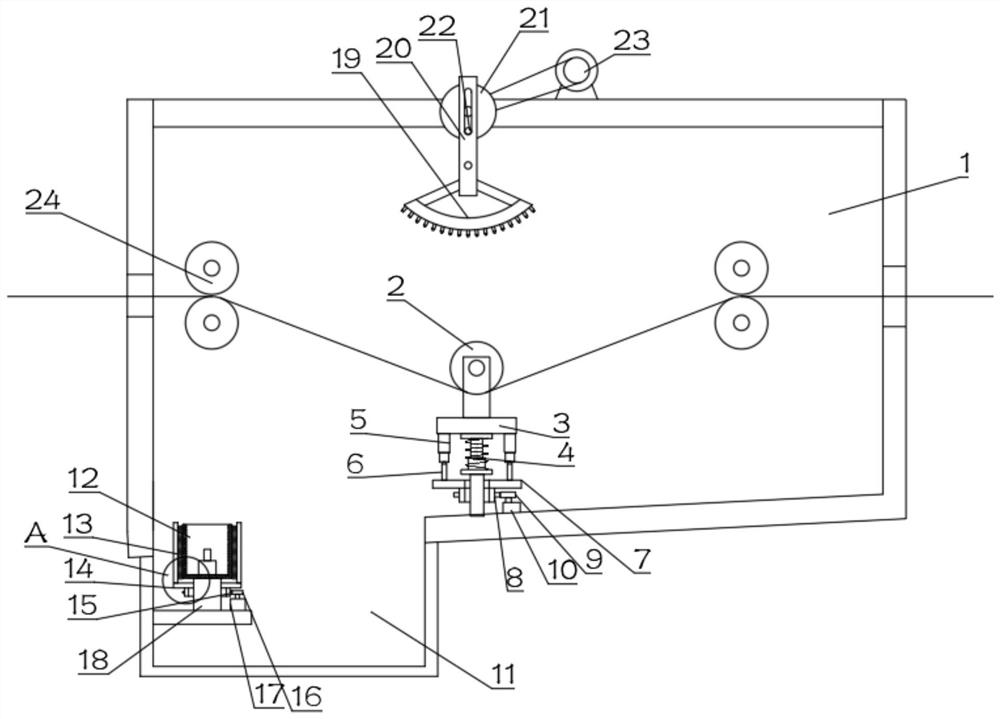

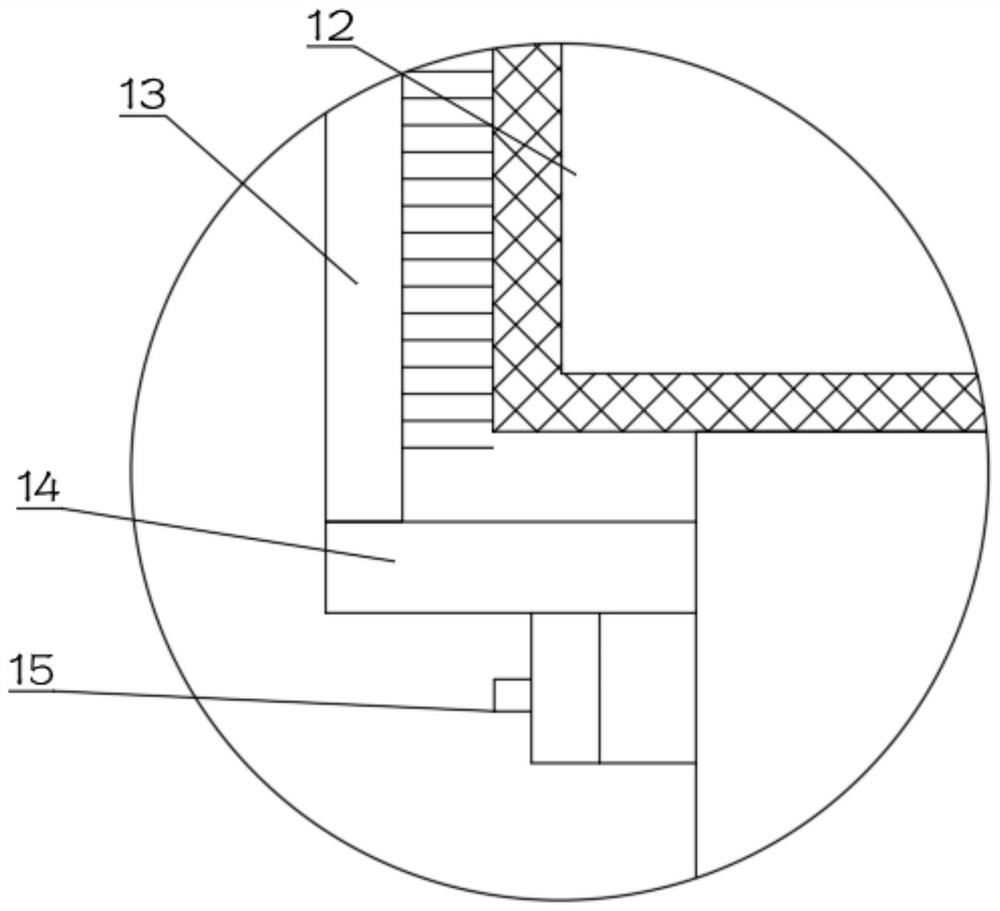

[0022] see Figure 1~3 , in Embodiment 1 of the present invention, it is a structural diagram of a vibrating textile material washing device provided by the embodiment of the present invention, including: a device main body 1, and there are feeding wheels 24 on both sides of the device main body 1, and the two sides are A pinch wheel 2 is arranged between the feed wheels 24, and the cloth passes through the feed wheels 24 and the pinch wheels 2 on both sides; the pinch wheels 2 are set up and down by jumping up and down; 3; the main body 1 of the device is provided with a jumping mechanism that drives the jumping of the supporting frame 3; the supporting frame 3 drives the pressing wheel 2 to jump up and down, and then drives the material passed on the pressing wheel 2 to jump up and down, thereby improving the cleaning effect;

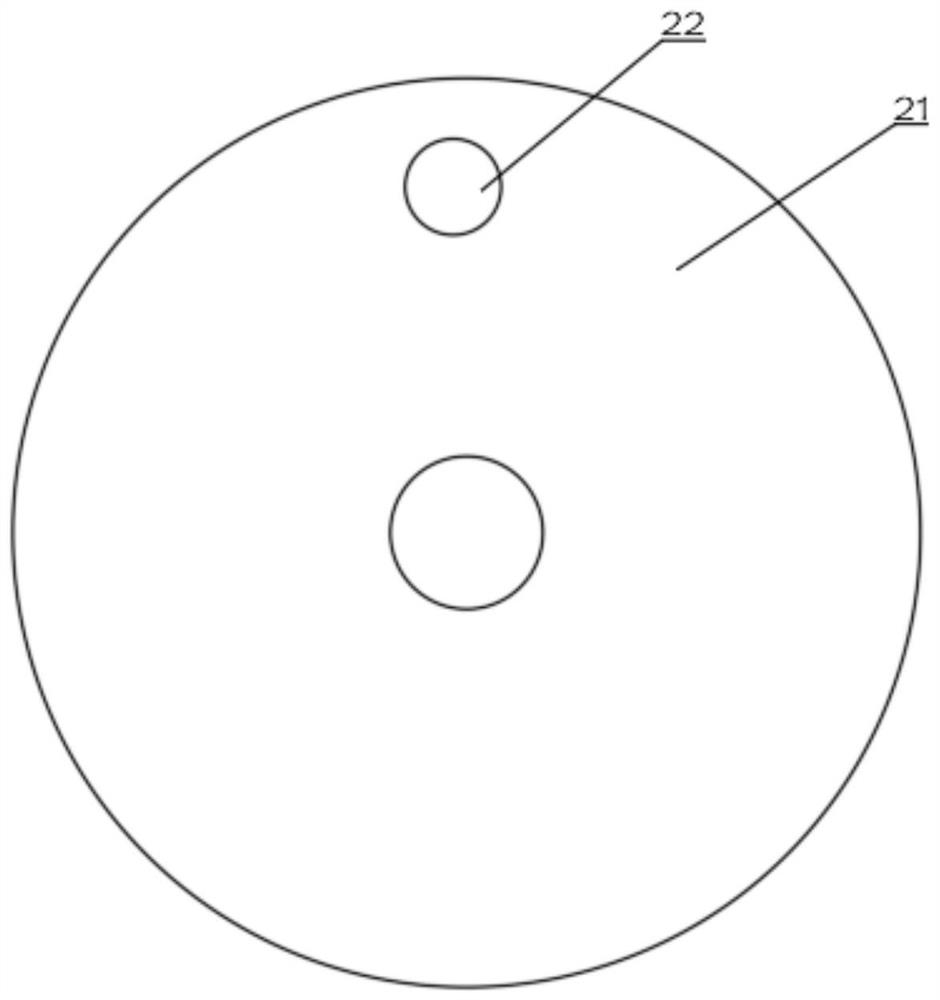

[0023] The device main body 1 is provided with a swinging arc-shaped plate 19, and the bottom of the arc-shaped plate 19 is provided with a plurality...

Embodiment 2

[0027] see Figure 1~3 The main difference between this embodiment 2 and embodiment 1 is that the jumping mechanism includes a drive ring 5 fixedly installed at the bottom of the support frame 3 and a drive rod 6 whose upper end touches the drive ring 5, and the drive rod 6 is fixedly mounted on On the self-rotating support 7, the drive rod 6 is two symmetrically arranged, and the drive ring 5 is symmetrically provided with arc grooves. Specifically, when the support 7 drives the drive rod 6 to rotate, the drive rod 6 Intermittently drawn into the arc groove, enter the drive ring 5 to drive the support frame 3 to reciprocate up and down, and then drive the support frame 3 to reciprocate up and down; drive the compression wheel 2 and the textile material on the compression wheel 2 to jump up and down, Realize the beating cleaning of raw materials. The arc-shaped groove is arranged on the rotation track of the driving rod 6 .

[0028] The lower end of the support frame 3 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com