Quantitative cutting device for aluminum sectional materials

A technology for cutting devices and aluminum profiles, applied in the direction of shearing devices, shearing machine accessories, shearing machine equipment, etc., can solve the problem of inconvenient adjustment of cutting angles, and achieve saving adjustment time, precise angle adjustment, and precise quantitative cutting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

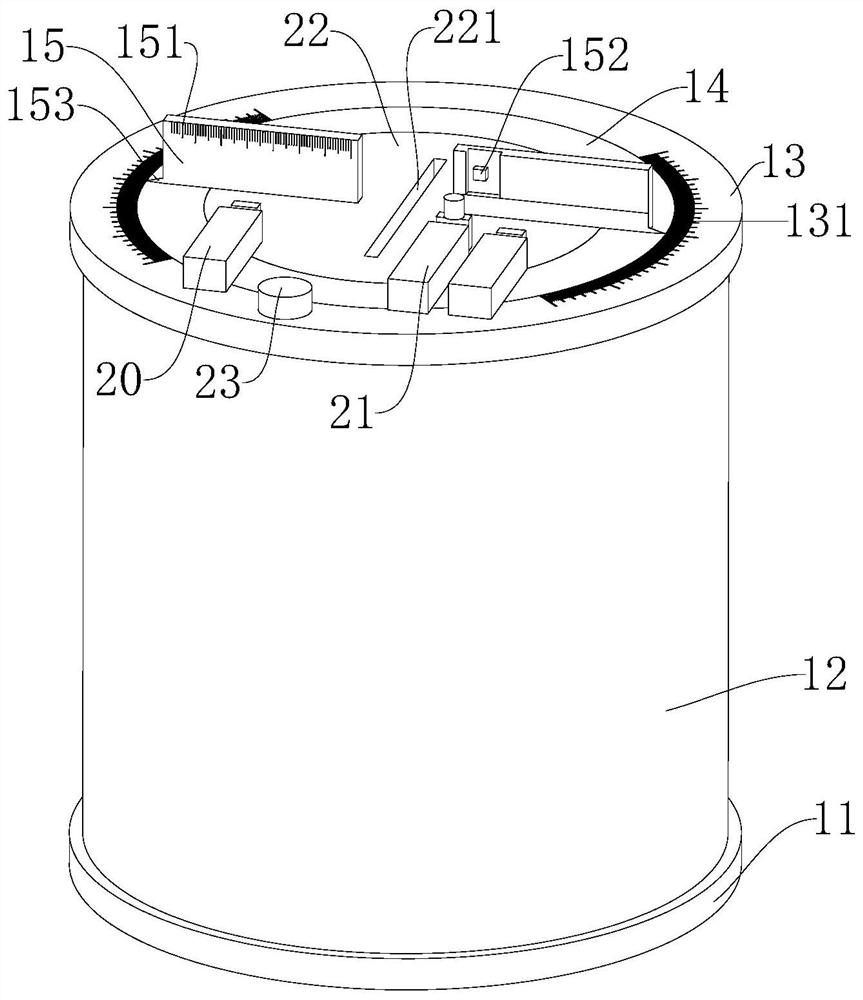

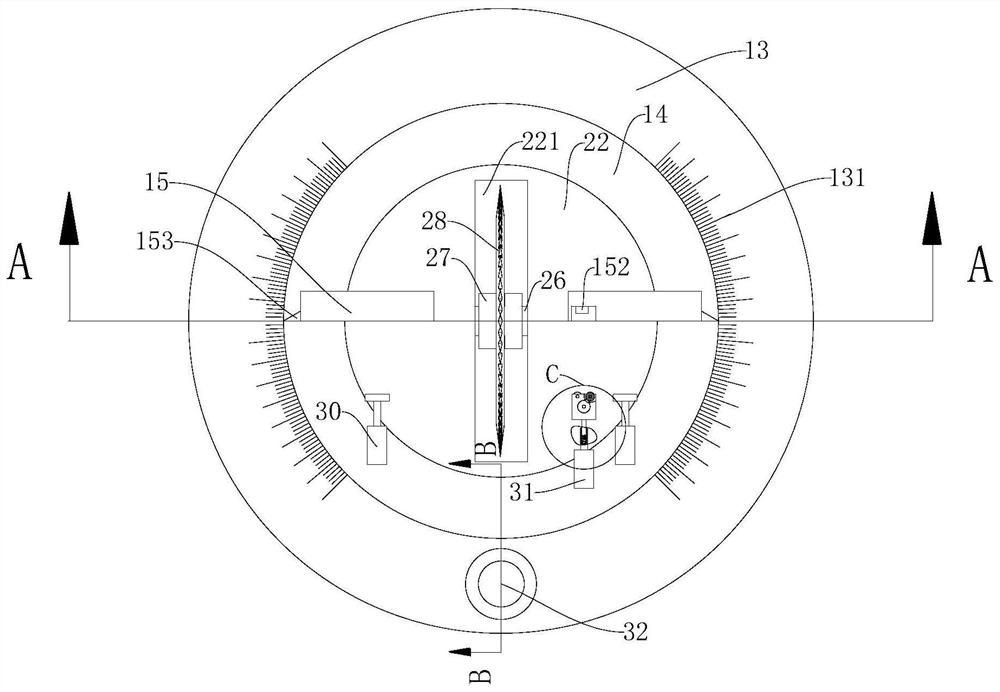

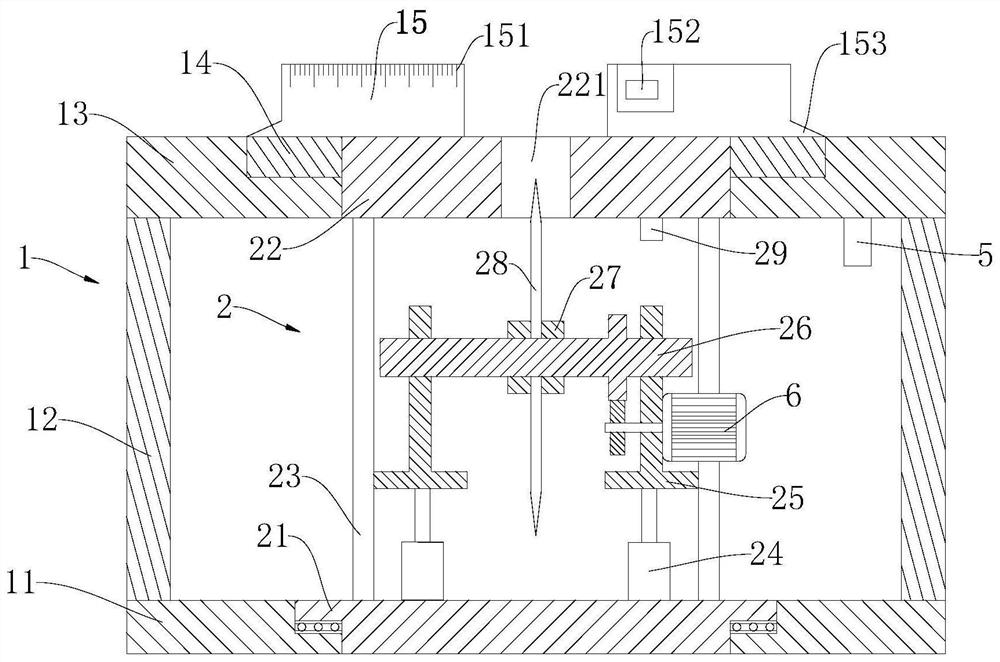

[0025] like Figure 1 to Figure 4 As shown, an aluminum profile quantitative cutting device provided by the embodiment of the present invention includes a body 1, a cutting device 2 and an adjusting device 32, wherein:

[0026] The body 1 comprises a base 11, a side wall 12, an upper support plate 13, a sliding ring plate 14 and a positioning plate 15, the upper end of the base 11 is fixedly connected with a side wall 12, and the upper end of the side wall 12 is fixedly connected with an upper support plate 13, and the upper support An annular chute is opened on the plate 13, and the sliding ring plate 14 is slidably arranged on the annular chute, the upper surface of the sliding ring plate 14 is flush with the upper surface of the upper supporting plate 13, and the two positioning plates 15 are respectively fixedly connected to the The different positions of the sliding ring plate 14, and the two positioning plates 15 are arranged on the same line, and the ends of the two pos...

specific Embodiment 2

[0031] In Embodiment 1, since the actual structure of the cutting device 2 usually affects the adjustment of the cutting angle of the aluminum profile, in order to achieve better multi-angle cutting, on the basis of Embodiment 2, as Figure 1 to Figure 4 As shown, the end face bearing 4 is also included in this embodiment, and the cutting device 2 includes a lower pallet 21, an upper pallet 22, a support column 23, a first electric push rod 24, a support plate 25, a support shaft 26, a pressing block 27, Cutting sheet 28 and motor 6, lower supporting plate 21 is rotatably connected to base 11, and upper supporting plate 22 is rotatably connected in the give way groove, and the upper surface of upper supporting plate 22 is flush with the upper surface of upper support plate 13 , the outer circumference of the upper supporting plate 22 is provided with a fourth gear, the lower supporting plate 21 is fixedly connected with a number of supporting columns 23, the upper ends of the s...

specific Embodiment 3

[0035] In embodiment 2, due to the fact that in actual use, large batches of processing are often required, the practicability of manually adjusting the cutting length is not strong, in order to realize automatic control of fixed-length feeding, so on the basis of embodiment 2, such as Figure 1 to Figure 5 As shown, this embodiment also includes a second electric push rod 30 and a feeding arm 31, the two second electric push rods 30 are fixedly connected to the sliding ring plate 14, and the two second electric push rods 30 correspond to two A positioning plate 15 is arranged, and the output shaft of the second electric push rod 30 points to the positioning plate 15, and the output shaft of the second electric push rod 30 is fixedly connected with a pressing plate, and the pressing plate is covered with rubber;

[0036] The feeding arm includes a third electric push rod 311, a push rod 312, a slide rod 313, a spring 314, a third button 315, a support shell 316, a servo motor 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com