Special-shaped structure type household tofu pressing and forming device

A pressing and structural technology, applied in the field of household tofu pressing and forming devices, can solve the problems of unfavorable household use, complex structure, time-consuming and labor-intensive, etc., and achieve the effect of improving the effect, good flexibility and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

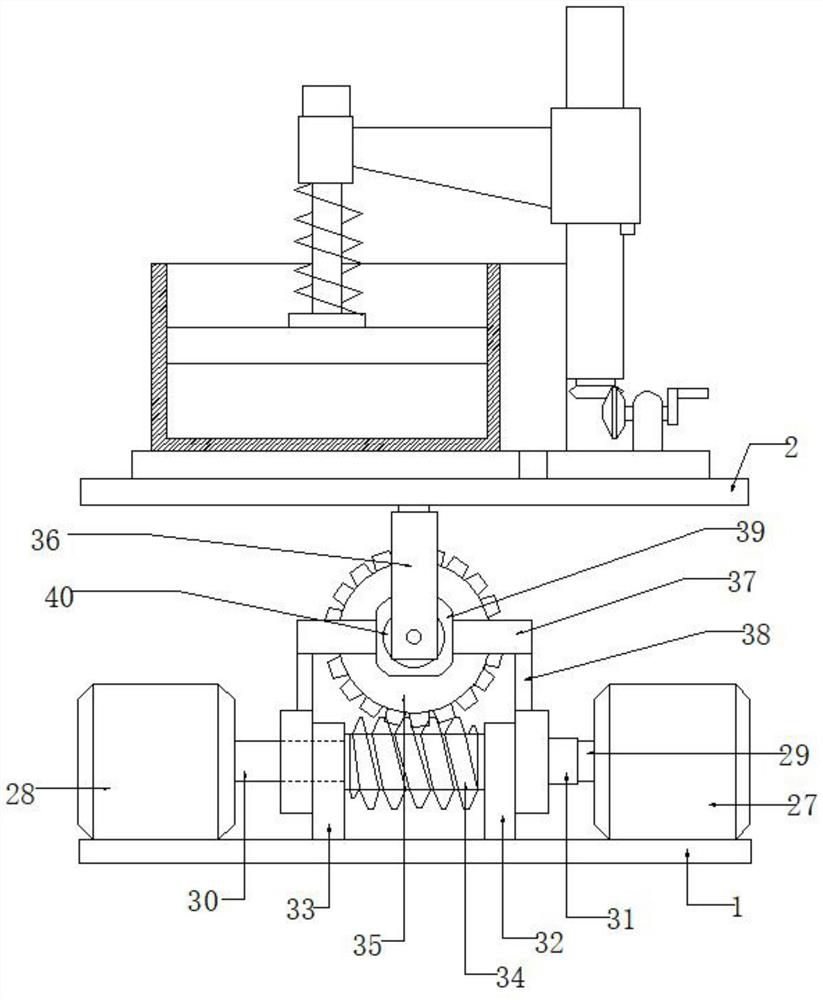

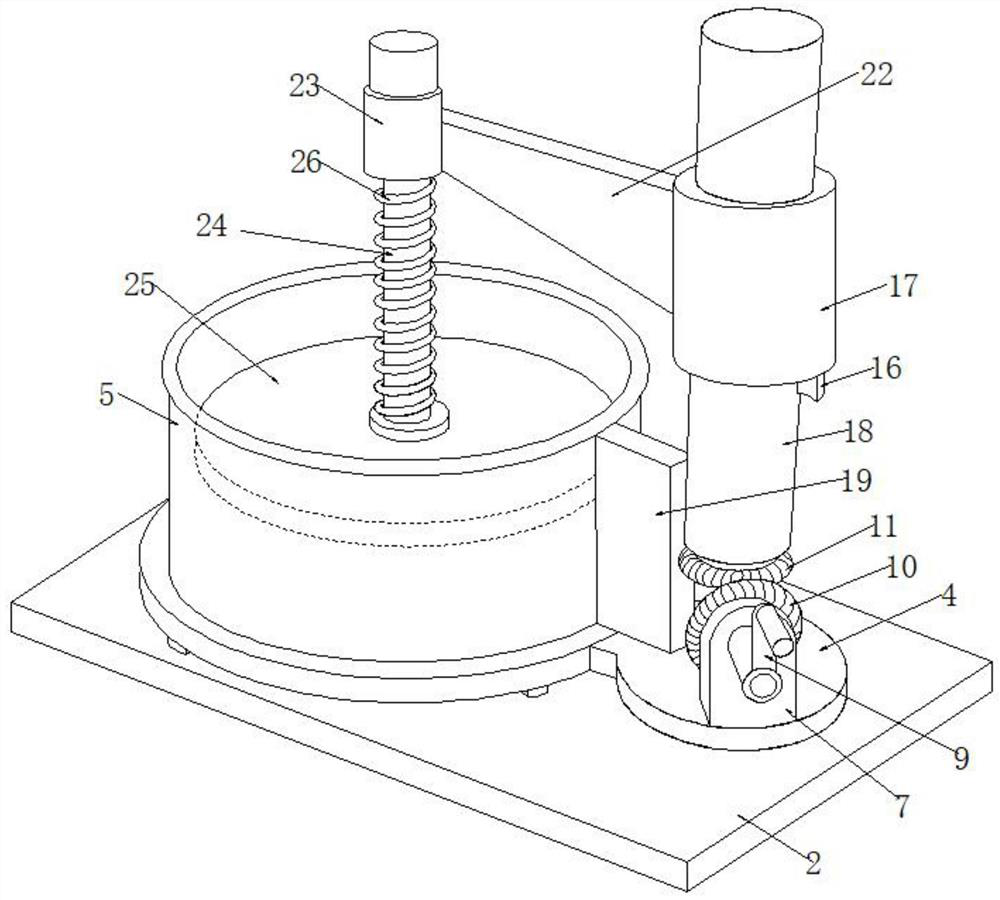

[0033] Such as Figure 1-7 displayed in:

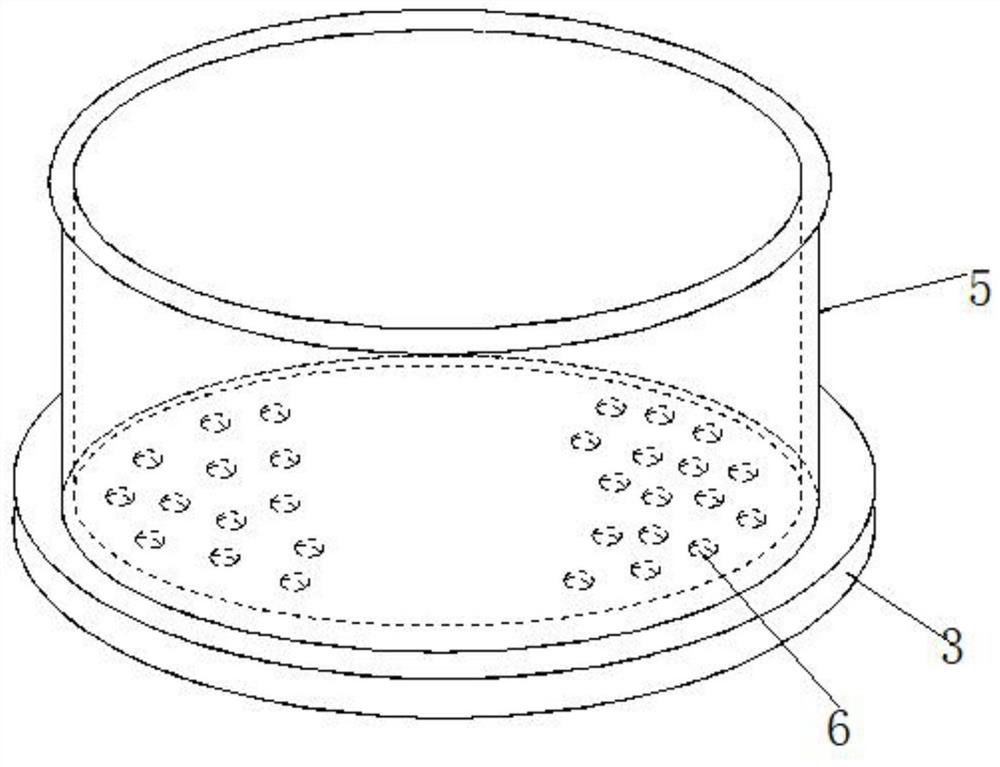

[0034] The present invention provides a special-shaped household bean curd press-forming device, which is suitable for use. Its structure includes a support base 1, a draining mechanism is provided on the top of the support base 1, and a support plate 2 is provided on the top of the draining mechanism. The top mold base 3 and the convex plate 4 of the plate 2, the top of the mold base 3 is provided with a mold body 5, and several drainage holes 6 are provided on both sides of the bottom of the mold body 5, and the drainage holes 6 are all The mold base 3 is penetrated, the bottom periphery of the mold base 3 is provided with several legs, and the legs are all fixed on the corresponding end of the top side of the support plate 2, wherein the convex plate The top of 4 is provided with pressing device.

[0035]In addition, the pressing device includes a support plate 7, the support plate 7 is fixed at the top outer end of the convex pl...

Embodiment 2

[0037] Such as figure 1 displayed in:

[0038] The present invention provides a special-shaped household bean curd press-forming device, which is suitable for use. Its structure includes a support base 1, a draining mechanism is provided on the top of the support base 1, and a support plate 2 is provided on the top of the draining mechanism. The top mold base 3 and the convex plate 4 of the plate 2, the top of the mold base 3 is provided with a mold body 5, and several drainage holes 6 are provided on both sides of the bottom of the mold body 5, and the drainage holes 6 are all The mold base 3 is penetrated, the bottom periphery of the mold base 3 is provided with several legs, and the legs are all fixed on the corresponding end of the top side of the support plate 2, wherein the convex plate The top of 4 is provided with pressing device.

[0039] In addition, the draining mechanism includes motor one 27, motor two 28, rotating shaft one 29, rotating shaft two 30, rotating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com