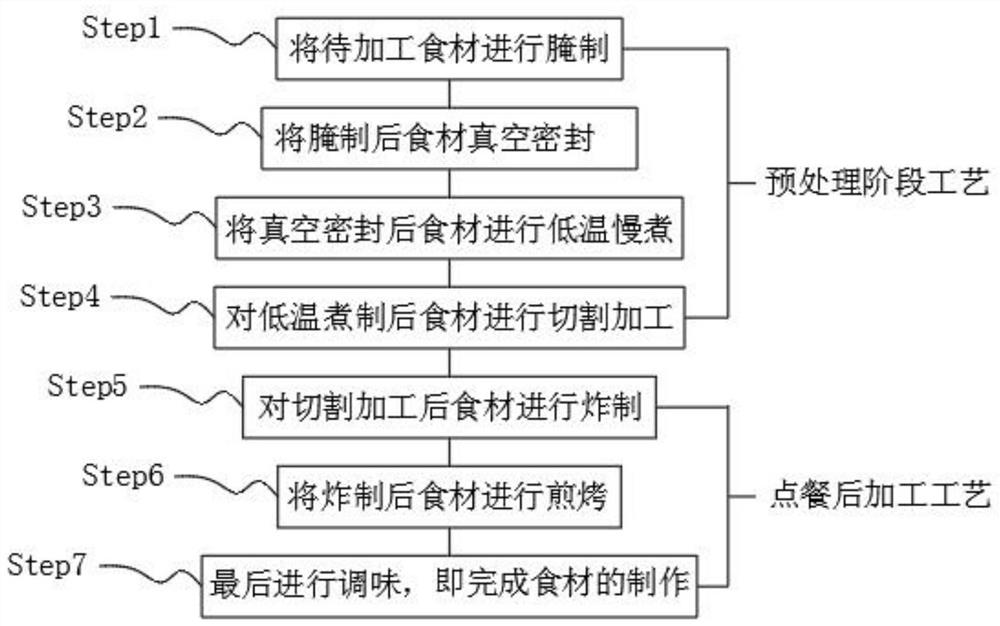

Barbecue process adopting low-temperature slow cooking technology

A process and low-temperature technology, which is applied in the field of low-temperature and slow-cooking barbecue technology, can solve the problems of uneven baked products, affecting the taste of food, and long baking time, so as to reduce oil fume emission pollution, shorten production time, and shorten the cooking time. Effect of Cooking Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Omit processing steps;

[0046] A: If marinating is omitted, it can be made by sealing, slow cooking at low temperature, cutting, frying, frying and seasoning. This can also achieve the production effect, but the moisture of the ingredients will be lost, and the taste will be different to a certain extent;

[0047] B: If frying is omitted, make it through Step1, Step2, Step3, Step4, Step6, and Step7. Step6 can make the food produce a charred layer, but the heat conduction is uneven, and the food is easy to be heat-proof. The degree of charring on each side is different, and the thickness is different. The place where the thin part is zoomed becomes hot, the outer layer of the thick part is burnt, and the inner part is cool;

[0048] C: If you omit frying and grilling, and make it through Step1, Step2, Step3, Step4, Step5, and Step7, you can also get close to the production effect, but only frying but not frying, the taste is greasy, and the taste of the outer burnt and ...

Embodiment 2

[0051] Alternate processing steps;

[0052] A: For example, replace pickling with water soaking to achieve the effect of sufficient moisture in the food;

[0053] B: For example, replace the vacuum seal with a non-vacuum seal, and then heat it with water, or steam it after sealing to achieve the effect of heating the food while retaining the moisture in the food (but more moisture will be lost);

[0054] C: For example, replace the water used in low-temperature slow cooking with heat-conducting liquids such as oil and salt water to achieve the effect of evenly heating food in a heating environment;

[0055] D: For frying or frying, or both, replace it with electric grill, charcoal grill or gas grill to achieve rapid heating effect (need to cook at low temperature and slow in advance), but the heating speed is slower than frying;

[0056] E: Such as replacing cutting processing with semi-finished products (such as threaded string products).

Embodiment 3

[0058] change the production order;

[0059]A: For example, the three steps of pickling, vacuum sealing and low-temperature slow cooking are combined into two or one step;

[0060] ① Put the marinade into a vacuum bag, marinate in a vacuum environment, and then cook slowly at low temperature;

[0061] ②. After vacuum-sealing the marinade and the food, start low-temperature and slow cooking, so that the food will gradually taste during the heating process and have a marinating effect.

[0062] B: If it is pre-cut and processed, pickling, vacuum sealing and low-temperature slow cooking can also be carried out after the completion of the process, which can also achieve the effect of the food after it is made;

[0063] C: If frying and frying are interchanged, the effect after the food is made can also be achieved.

[0064] The present invention uses low-temperature slow cooking, frying, frying or teppanyaki instead of traditional open fire barbecue, which greatly shortens the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com