One-button start-stop and interlock protection control method of jet pump in condenser vacuum system

A vacuum system and interlock protection technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the lack of automatic control methods and interlock protection of software, affecting the stability of the vacuum system of large machines, and auxiliary steam pressure disturbances, etc. problem, to achieve the effect of simplifying operation, ensuring safety and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

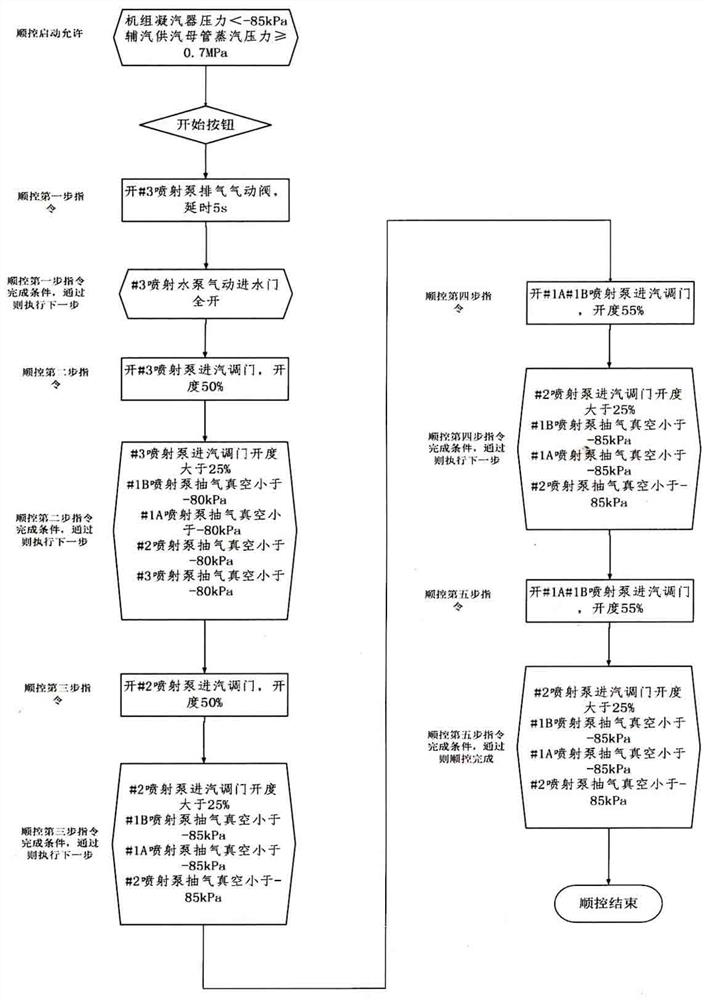

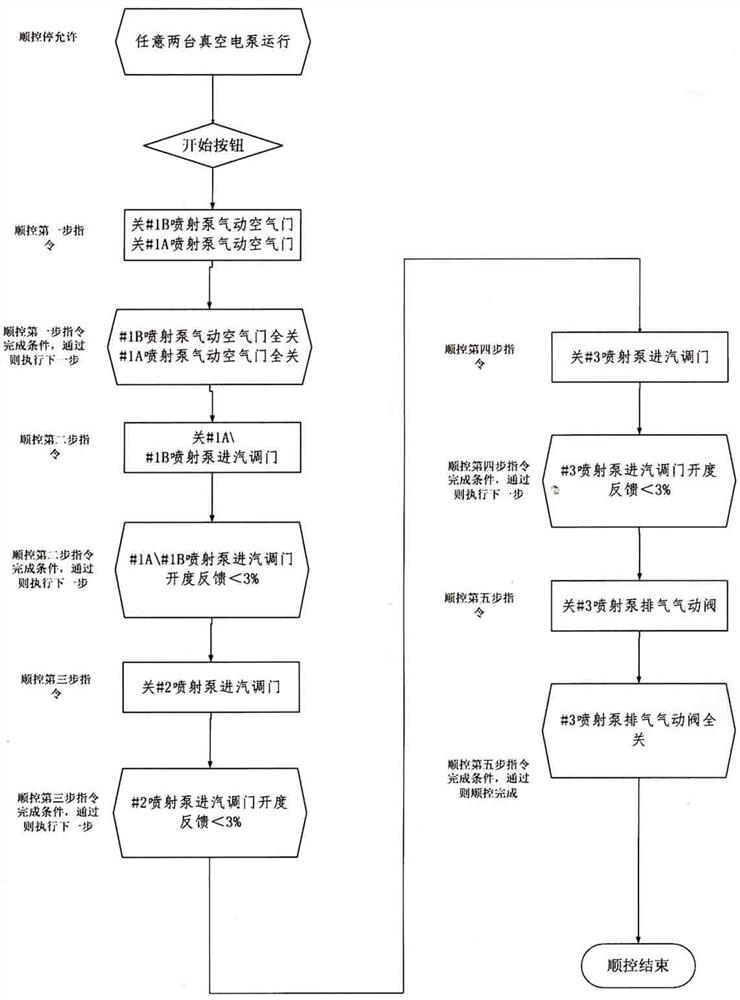

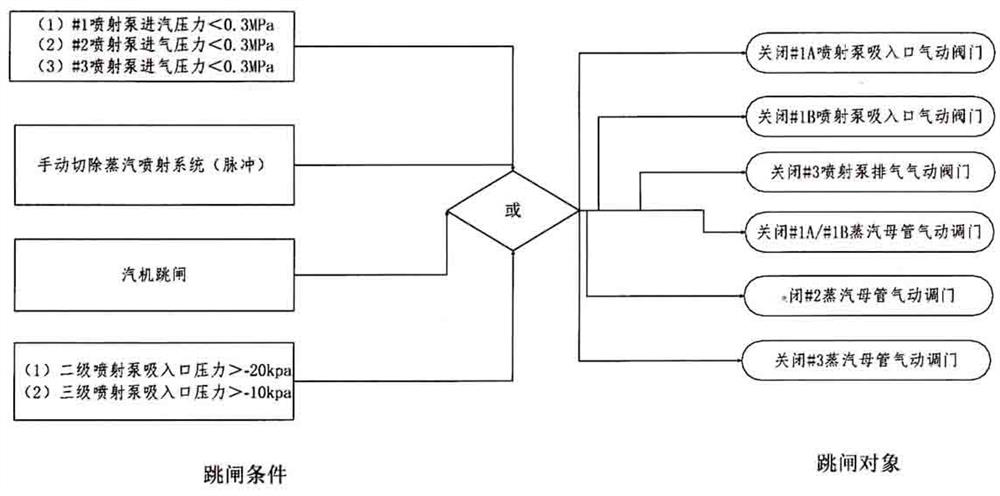

Embodiment Construction

[0052] One-button start stop and interlocking protection method of a condenser vacuum system jet pump, which includes a pump portion and a steam ejection portion, and three electric pumps in the electric pump portion, and two steam spray portions are disposed. Taiwan first-stage jet pump A, B, one secondary jet pump, a three-stage jet pump and one-stage heat exchanger, secondary heat exchanger, three-stage heat exchanger; four injection pump power steam sources Compappose mother tube, the suction port of the primary jet pump A, B is connected to the inhale port of the three electric pumps in the condenser vacuum female, the power steam after the spray pump is moving into the first-stage heat exchanger, steam in one After the grade heat exchanger is condensed, it is then inhaled to the secondary heat exchanger after the secondary spray pump, and then the three-stage jet pump is inhaled to the three-stage heat exchanger, and finally hydrophobic to condensed water heating well;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com