One-key start-stop and interlock protection control method for jet pump of condenser vacuum system

A vacuum system and interlock protection technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the lack of automatic control methods and interlock protection of software, affecting the stability of the vacuum system of large machines, and auxiliary steam pressure disturbances, etc. problem, to achieve the effect of simplifying operation, ensuring safety and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

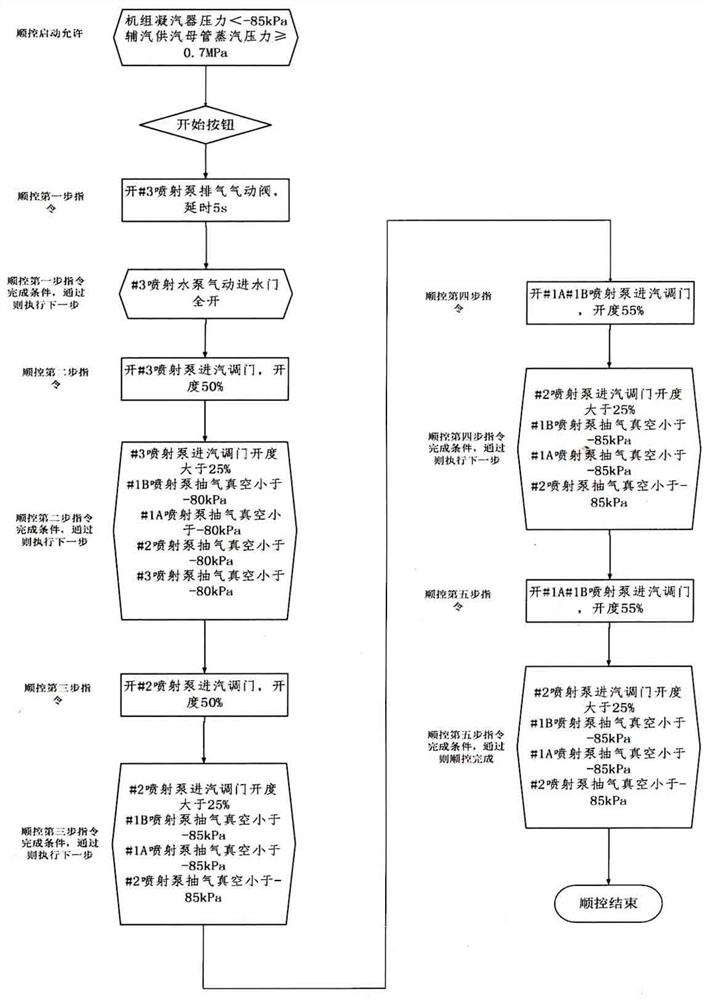

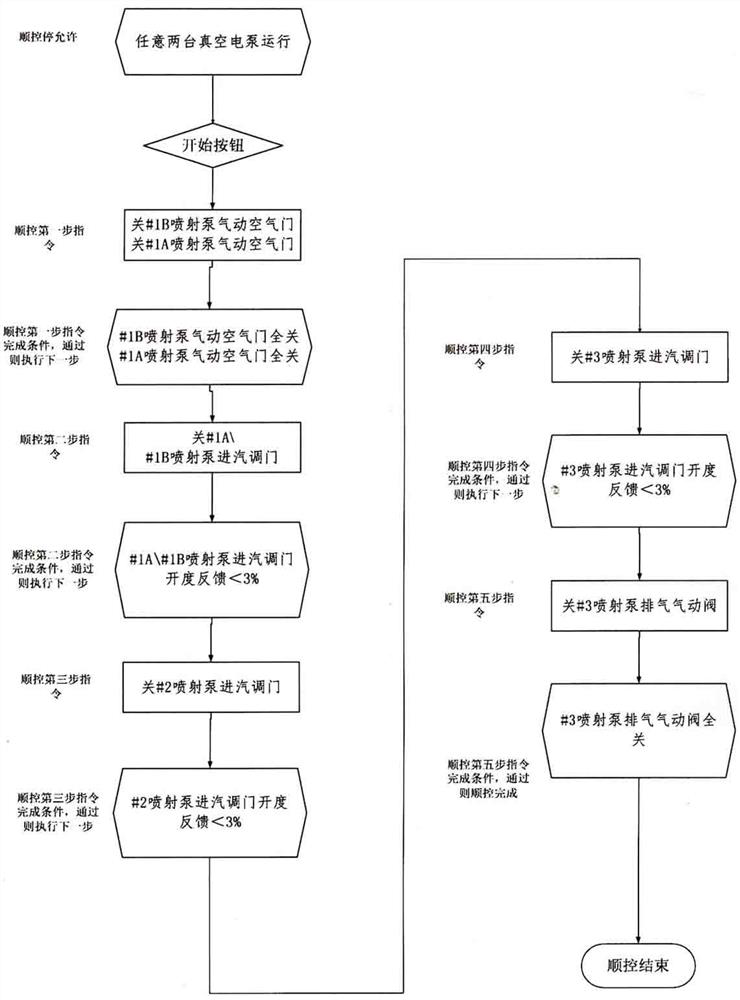

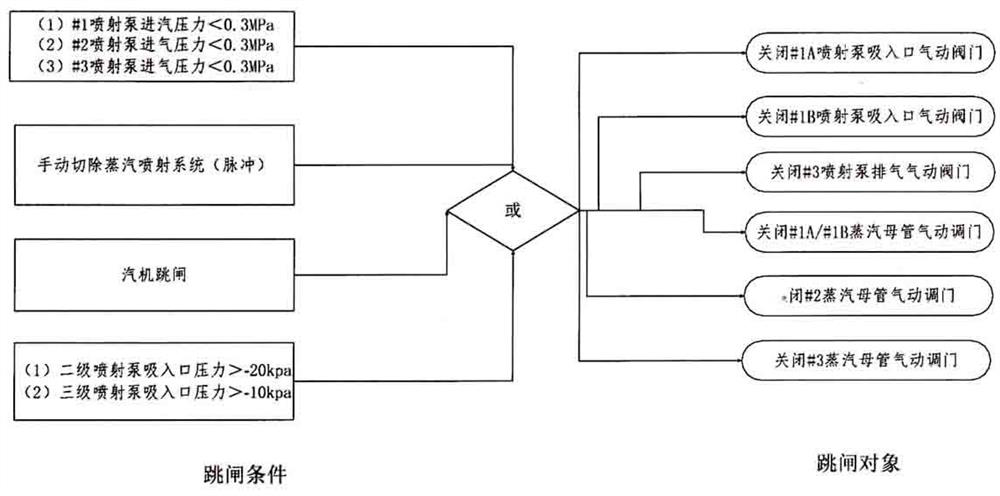

[0052] A one-button start-stop and interlock protection control method for a jet pump in a condenser vacuum system, the condenser vacuum system includes an electric pump part and a steam injection part, the electric pump part has three electric pumps, and the steam injection part is equipped with two One first-stage jet pump A, B, one second-stage jet pump, one third-stage jet pump, first-stage heat exchanger, second-stage heat exchanger, and third-stage heat exchanger; the power steam source of the four jet pumps is The auxiliary steam main pipe, the suction ports of the primary jet pumps A and B and the suction ports of the three electric pumps are all connected to the vacuum main pipe of the condenser. After the first-stage heat exchanger is cooled by condensate, it is sucked by the second-stage jet pump and discharged to the second-stage heat exchanger. After cooling again, it is sucked by the third-stage jet pump and discharged to the third-stage heat exchanger, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com