Novel centrifugal nozzle of combustion chamber of gas turbine

A gas turbine, centrifugal nozzle technology, applied in the combustion chamber, continuous combustion chamber, combustion method, etc., to achieve the effect of enhancing the scope and breadth of application, reducing emissions, and increasing combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing:

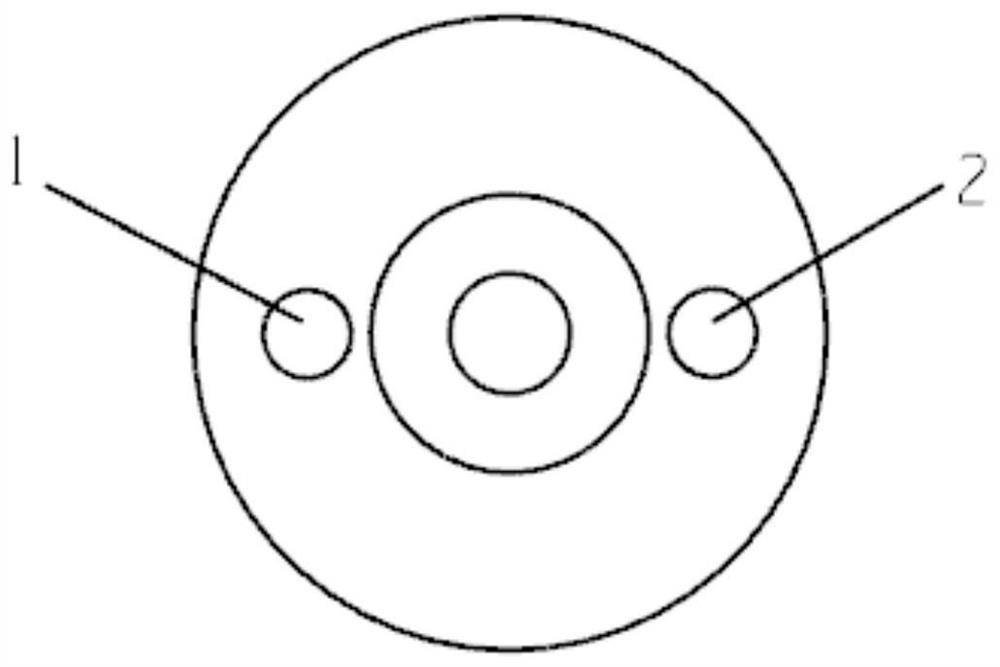

[0021] combine figure 1 The overall appearance of the centrifugal nozzle of a new type of gas turbine combustor, figure 2 Global cross-sectional view of a novel centrifugal nozzle for a gas turbine combustor, image 3 Fuel inlet / nozzle tail diagram of a new type of centrifugal nozzle for gas turbine combustor A new type of centrifugal nozzle for gas turbine combustor is realized, the invention can strengthen the atomization effect, achieve high combustion efficiency and low emission.

[0022] Specific process: the fuel enters the main oil passage under a certain pressure ( figure 2 1) in the auxiliary oil passage (2 in Figure 2), passing through the cyclone at the end of the straight passage of the oil passage ( figure 2 6) realizes the high-speed rotation of the fuel, passes through the outlet of the contraction section of the fuel road, and the swirl blades of the swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com