Intelligent manufacturing device capable of guaranteeing slurry uniformity and discharging quality

A technology of intelligent manufacturing and uniformity, which is applied in the processing of textile materials, the configuration of equipment for processing textile materials, textiles and papermaking, etc. It can solve the problems of low stirring efficiency and discharging efficiency, and inability to intelligently control stirring speed and discharging speed. , to achieve the effect of improving mixing efficiency and preventing energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

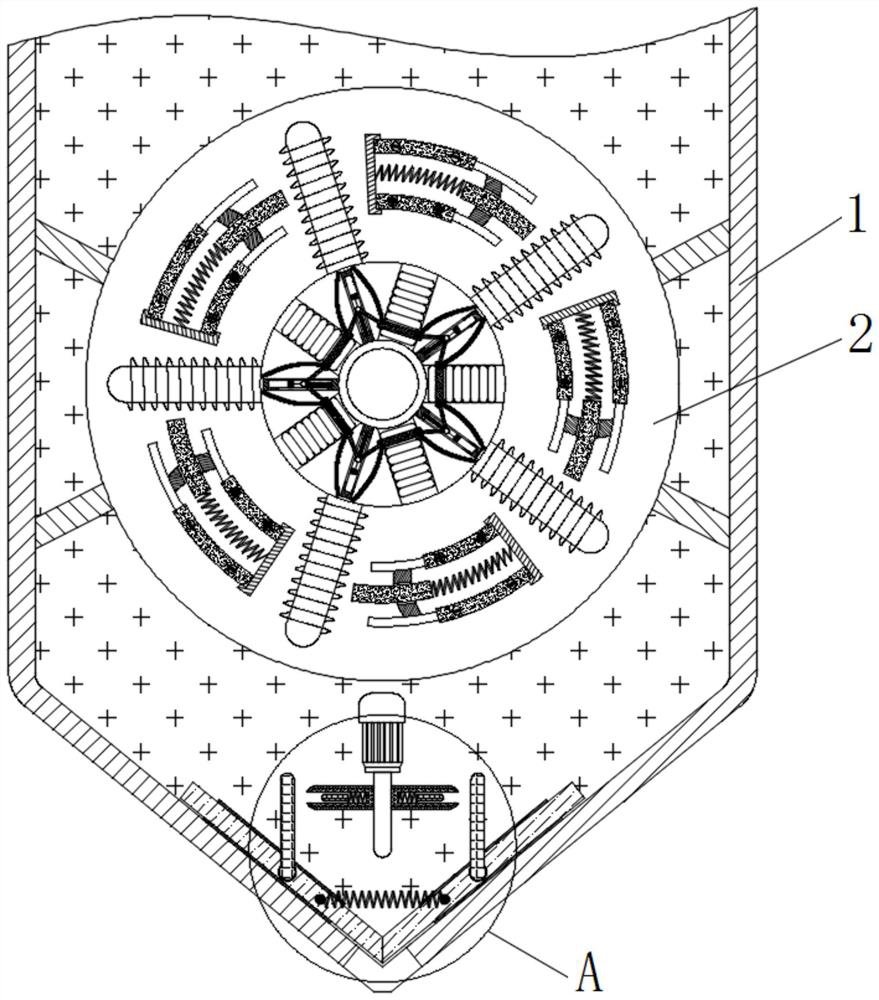

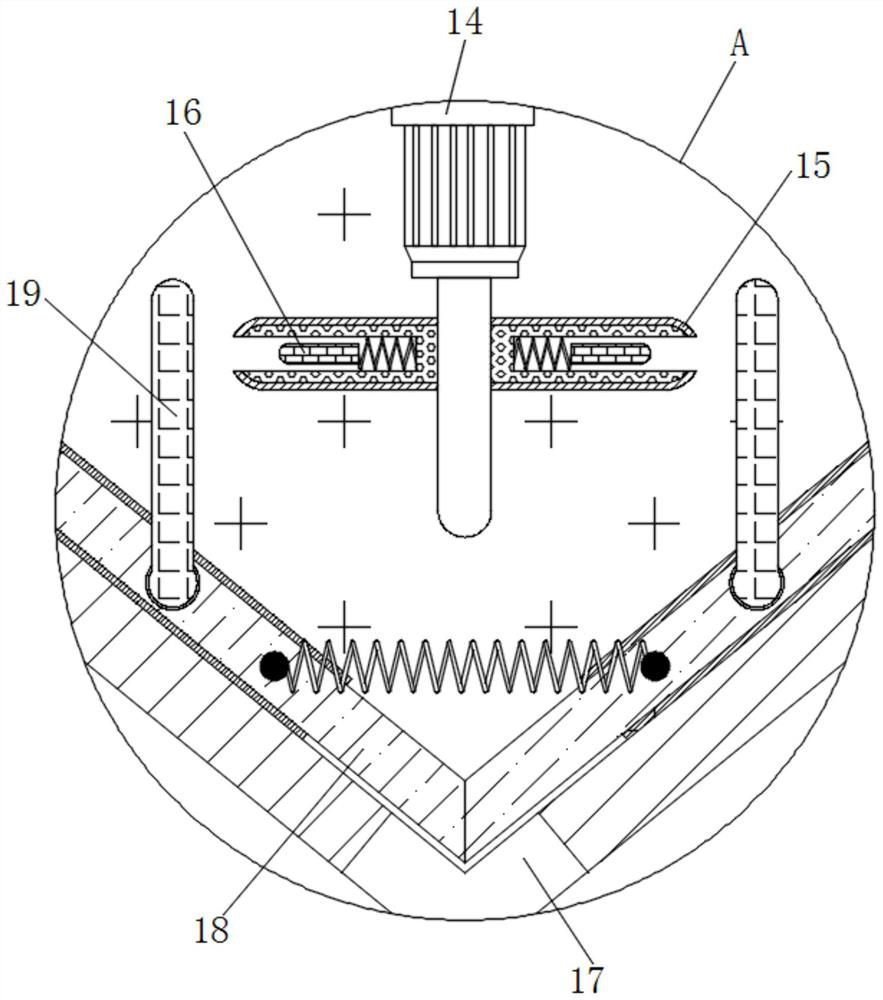

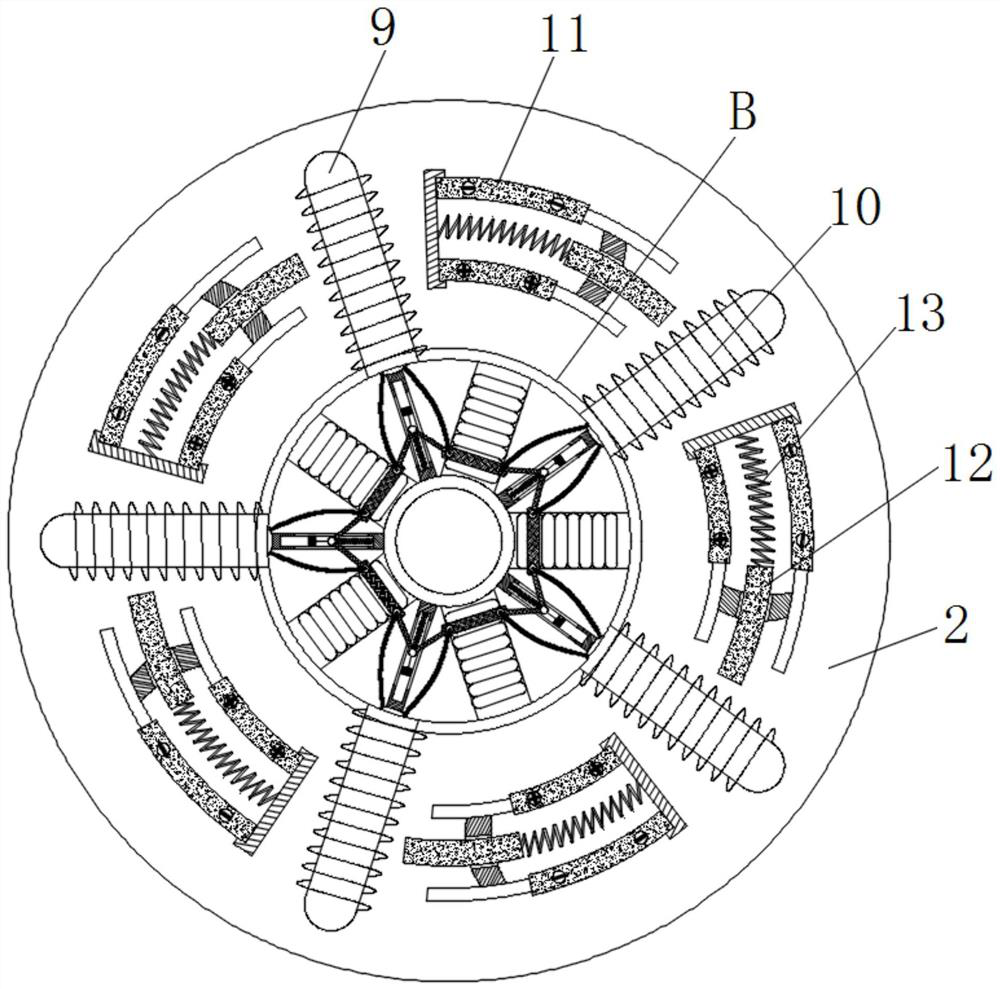

[0025]SeeFigure 1-5A device that intelligently manufactures ensures the uniformity of the slurry and the mass of the mass, including the housing 1, and the internal rotation of the housing 1 is rotated and mounted, and the left and right sides of the stirring pan 2 surface of the stirring plate is fixedly mounted. After the coil 10 is turned to the magnetic field, the center of the stirring pan 2 is fixedly mounted, the drive rod 3, the motor transmission connection, the outer fixed connection of the surface drive rod 3 of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com