A rear cross member structure, body frame assembly and automobile

A technology of rear beam and automobile, applied in the directions of superstructure sub-assembly, connection between superstructure sub-assemblies, superstructure, etc., can solve the problem of difficulty in realizing interior decoration and generalization of electrical appliances, inconvenience in design and production, and design cost. and production costs increase, to achieve the effect of low processing costs, saving design and production costs, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

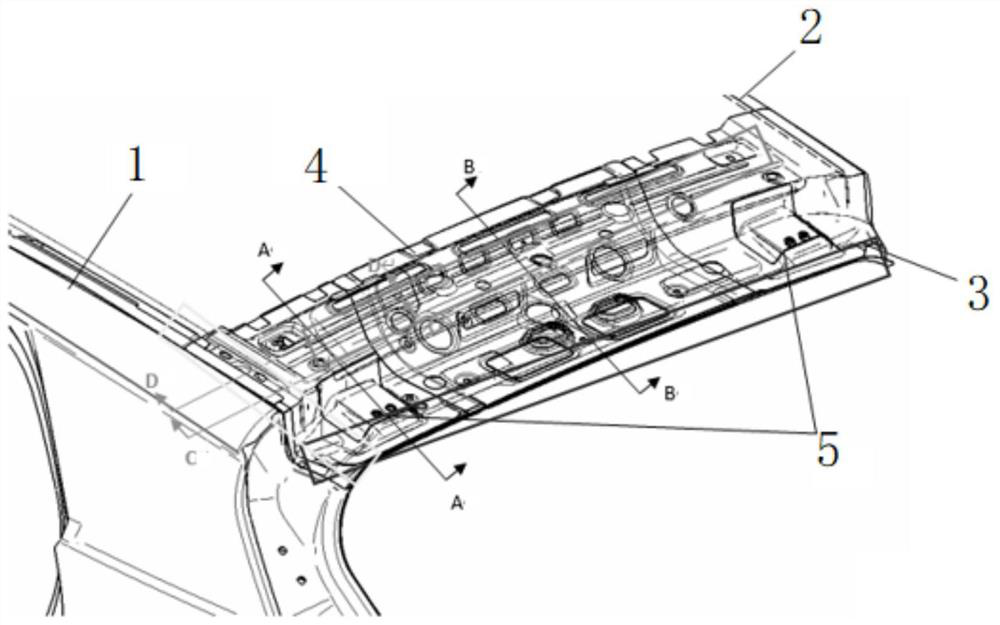

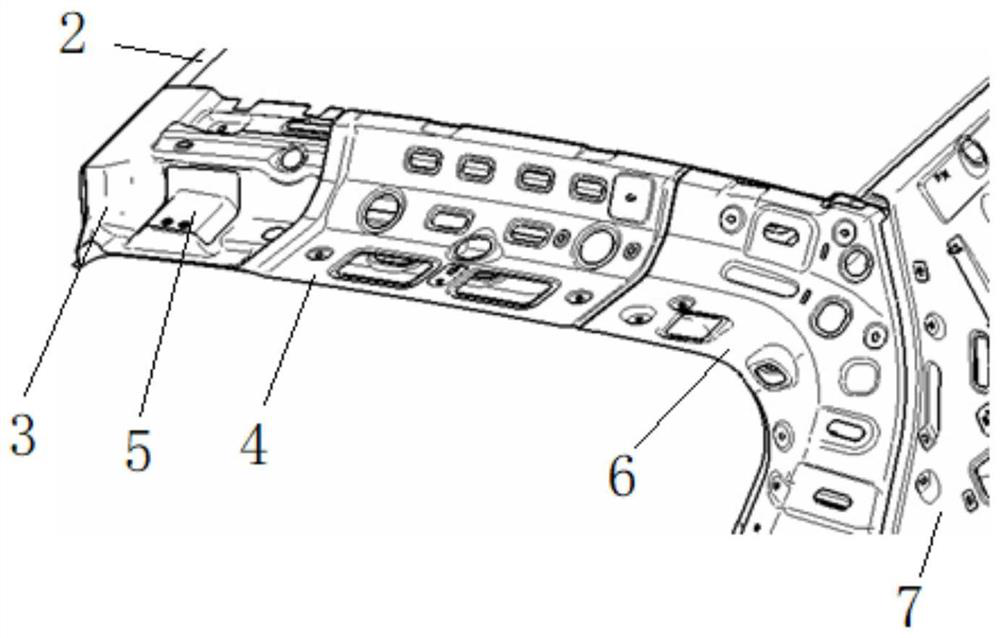

[0079] like Figure 1 to Figure 11 As shown, the present invention provides a rear beam structure, comprising:

[0080] The first rear cross member upper plate 3 and the second rear cross member upper plate 9;

[0081] The rear cross beam lower plate 4, the rear cross beam lower plate 4 is connected with the first rear cross beam upper plate 3 or the second rear cross beam upper plate 9;

[0082] The rear cross member outer plate 10 is connected with the second rear cross member upper plate 9;

[0083] The first rear cross beam upper plate 3 and the rear cross beam lower plate 4 form the first rear cross beam structure, and the first rear cross beam structure is used for the sheet metal roof vehicle;

[0084] The second rear cross beam upper plate 9, the rear cross beam lower plate 4 and the rear cross beam outer plate 10 form the second rear cross beam structure, and the second rear cross beam structure is used for the canopy roof vehicle.

[0085] Optionally, it also incl...

Embodiment 2

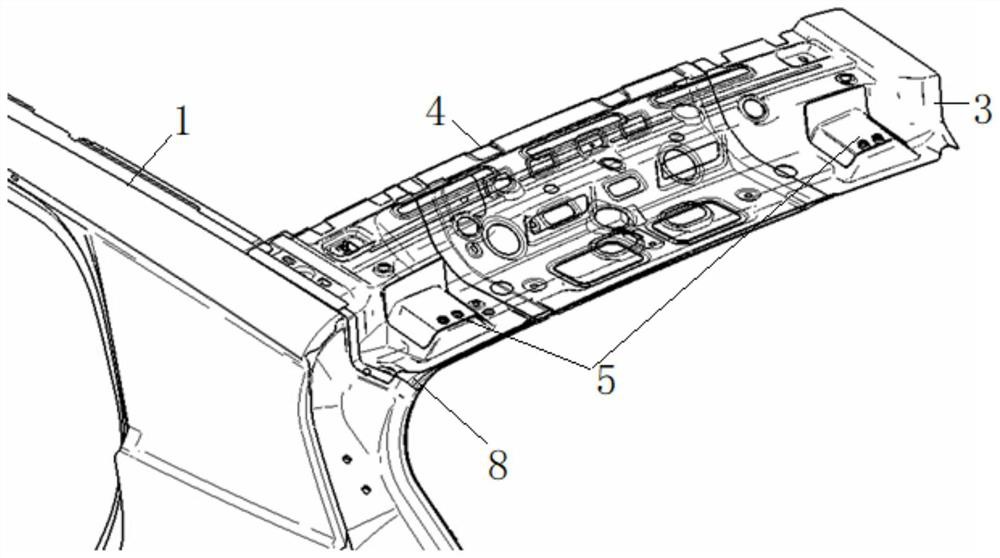

[0110] like Figure 12 to Figure 18 As shown, based on the rear cross member structure, the body frame assembly and the vehicle in the first embodiment, the difference between this embodiment and the first embodiment is that the vehicle in this embodiment is a canopy car, which adopts the second rear cross member structure. ; see Figure 12 , the canopy top cover assembly is only composed of a single piece of the rear beam outer plate 10, the second rear beam structure includes the second rear beam upper plate 9, the rear beam lower plate 4 and the left and right hinge reinforcement plates 5. The welding level is composed of a single piece. Consistent with the welding level of the sheet metal top in the first embodiment, that is, the D-pillar upper reinforcing plate 8 and the D-pillar upper inner plate 6 in the side wall assembly and the second rear cross member structure are connected together by structural glue and welding points to form the body. The frame sub-assembly, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com