Wide cold glue wall cloth production line

A technology for producing assembly lines and wall coverings, which is applied in the field of wide-width cold-adhesive wall covering production lines, and can solve the problems of easy idling of equipment, waste of production time, and increased labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

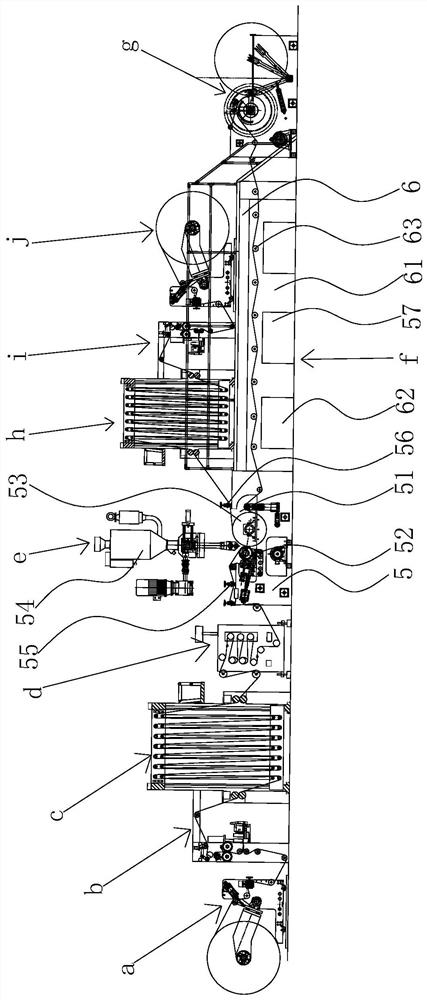

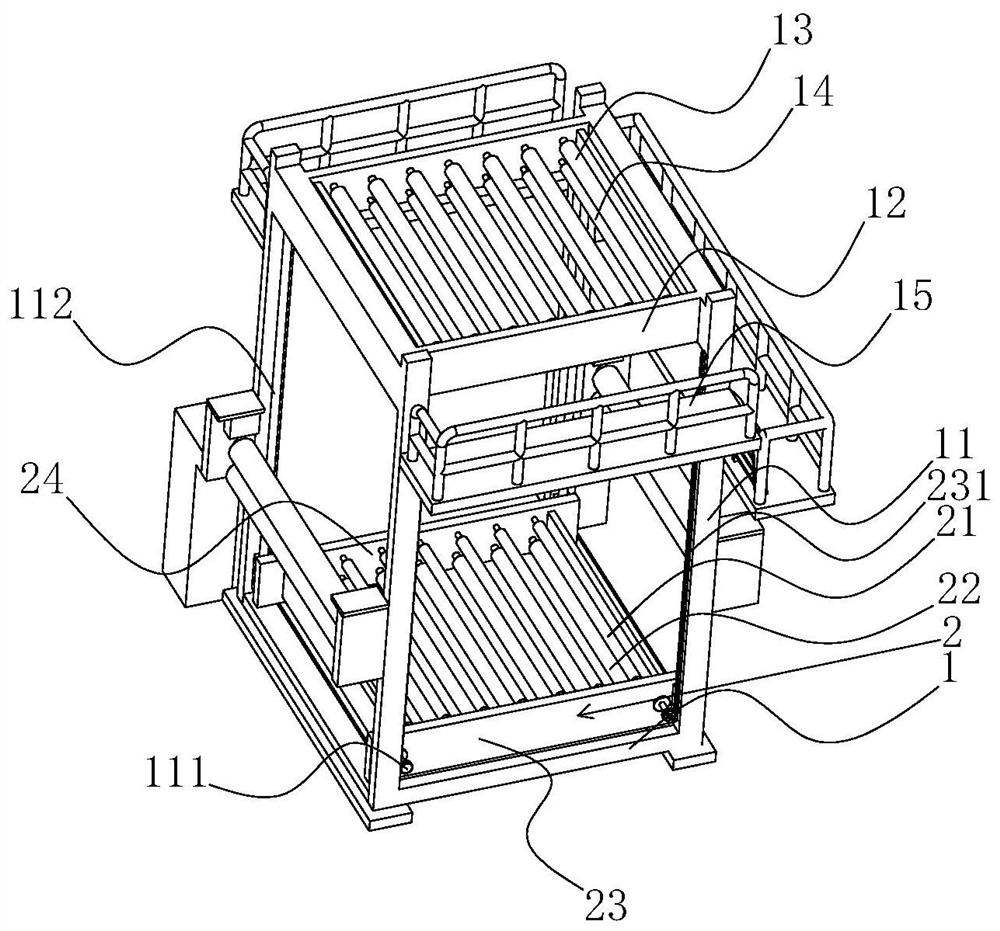

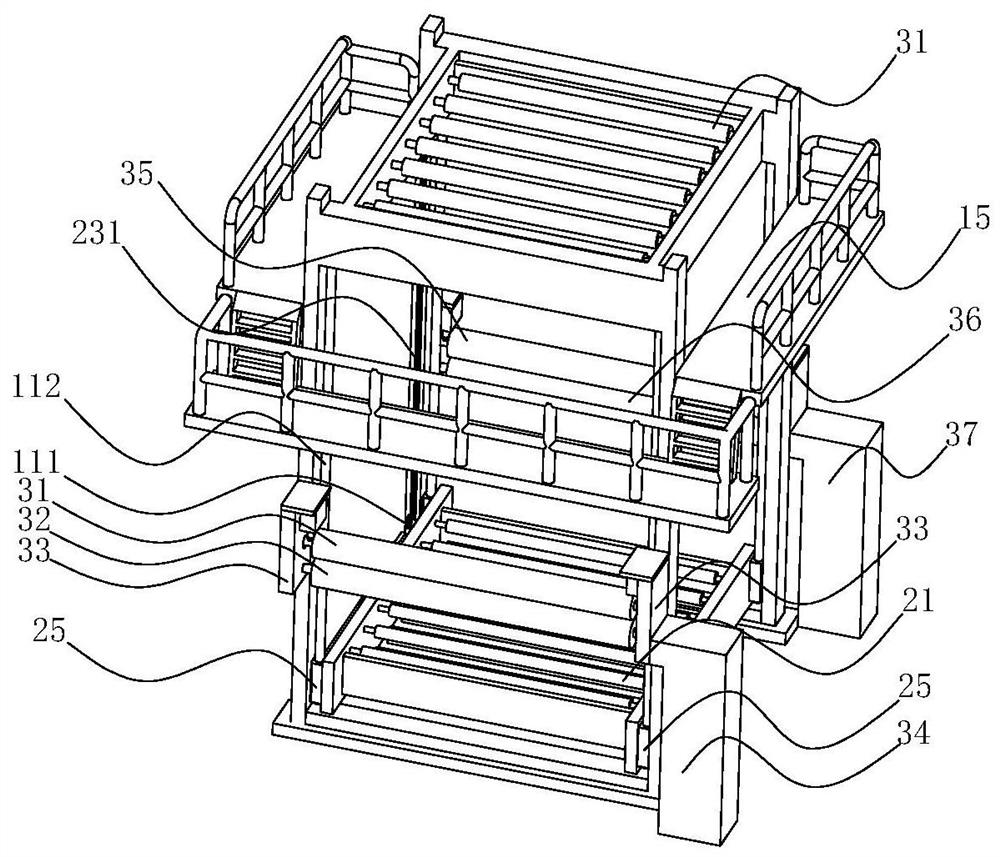

[0022] like Figure 1-7 As shown in the figure, a production line of wide-width cold glue wall coverings includes the wall covering automatic unwinding mechanism a, the first continuous sewing mechanism b, the first processing and storage mechanism c, the weft adjusting mechanism d, and the film forming Mechanism e, cooling mechanism f and automatic winding mechanism g, the top of the cooling mechanism f is successively provided with the second processing material storage mechanism h close to the side of the film forming mechanism e, the second continuous sewing mechanism i and the non-woven fabric automatic unwinding mechanism Roll mechanism j, the structures of the first continuous sewing mechanism b and the second continuous sewing mechanism i are equivalent, the structures of the first processing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com