Press with flexible supporting platform

A technology of flexible support and hydraulic support platform, applied in the direction of presses, stamping machines, metal processing, etc., can solve the problems of workpiece pressure damage and achieve the effect of overcoming workpiece damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

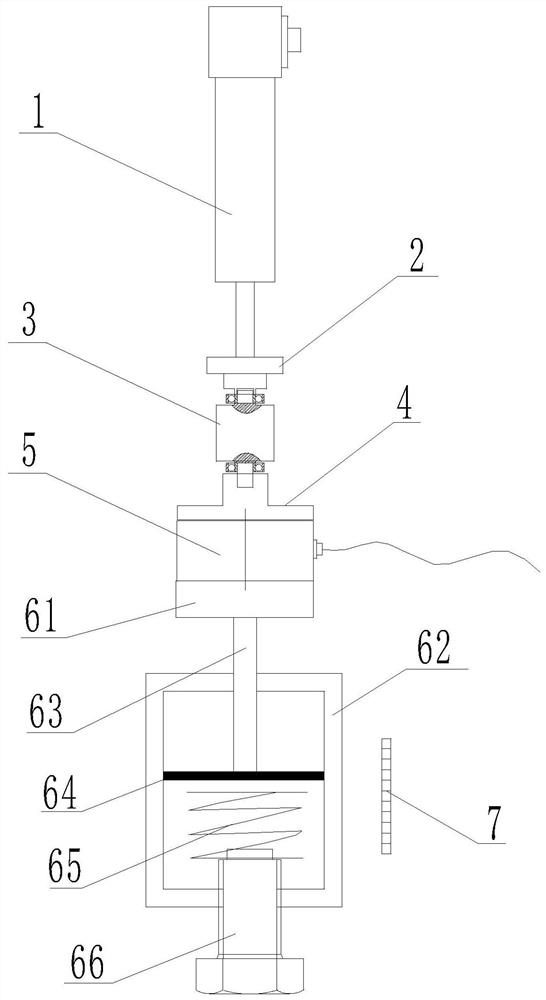

[0026] Such as figure 2 As shown, the flexible support platform 6 is a spring support platform, and the spring support platform includes a first piston cylinder 62, a first piston 64 is slidably connected in the first piston cylinder 62, and a first piston rod 63 is fixedly installed on the upper end of the first piston 64. , the upper end of the first piston rod 63 passes through the first piston cylinder 62 and is slidably connected with the first piston cylinder 62, the upper end of the first piston rod 63 is fixedly connected with a first support plate 61, and the first support plate 61 is located at the pressure sensor 61, when the driving device 1 presses the workpiece 3, the first piston 64 moves downward;

[0027] The lower end of the first piston cylinder 62 is threadedly connected with an adjusting bolt 66, and the upper end of the adjusting bolt 66 passes through the lower end of the first piston cylinder 62, and is connected with a first spring 65 at the end, one ...

Embodiment 2

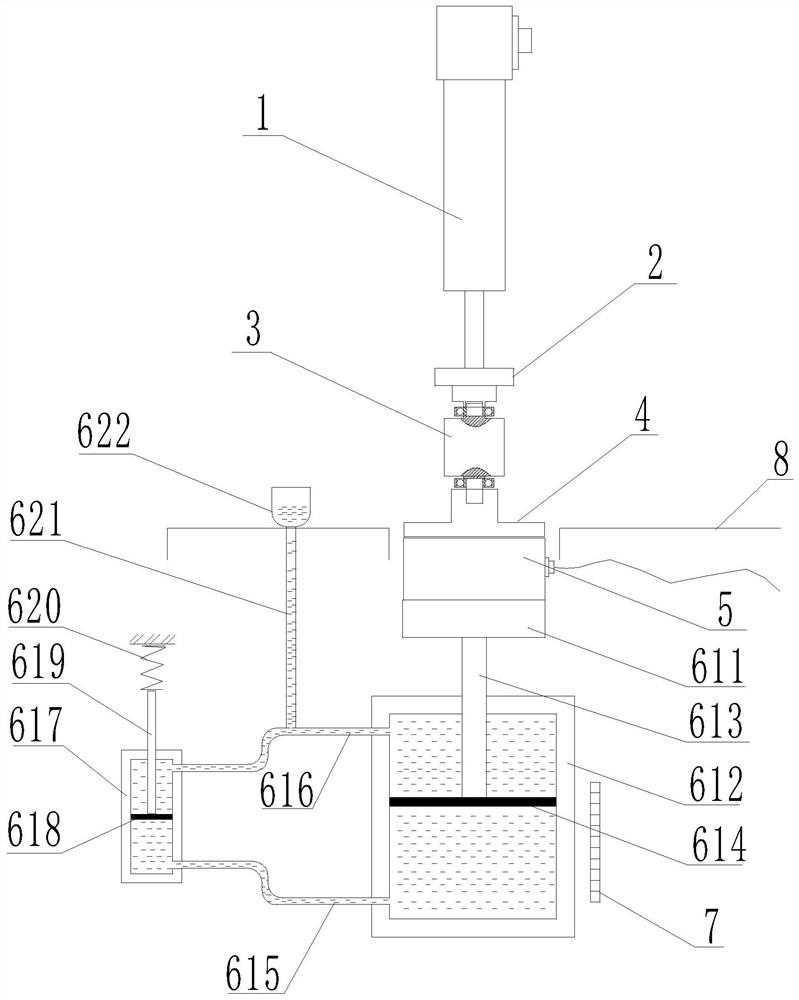

[0030] Such as image 3 As shown, the flexible support platform 6 is a hydraulic support platform; the hydraulic support platform includes a second piston cylinder 612, which is filled with oil, and is slidably connected to a second piston 614 in the second piston cylinder 612, and the second piston 614 Cooperate with the second piston cylinder 612; the upper end of the second piston 614 is fixedly installed with the second piston rod 613, the second piston rod 613 is slidingly connected with the second piston cylinder 612, and the upper end of the second piston rod 613 is fixedly installed with the second piston rod 613 Two supporting plates 611, the second supporting plate 611 is located at the lower end of the pressure sensor 5; when the driving device 1 presses the workpiece 3, the second piston 614 moves downward;

[0031] One side of the second piston cylinder 612 is equipped with a third piston cylinder 617, a first oil pipe 615 and a second oil pipe 616 are connected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com