Production process of soft cotton high-elasticity paper diaper

A production process and technology of diapers, applied in the field of hygiene products, can solve the problems of low production process efficiency and achieve the effects of promoting and using, improving absorption capacity, and improving production and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

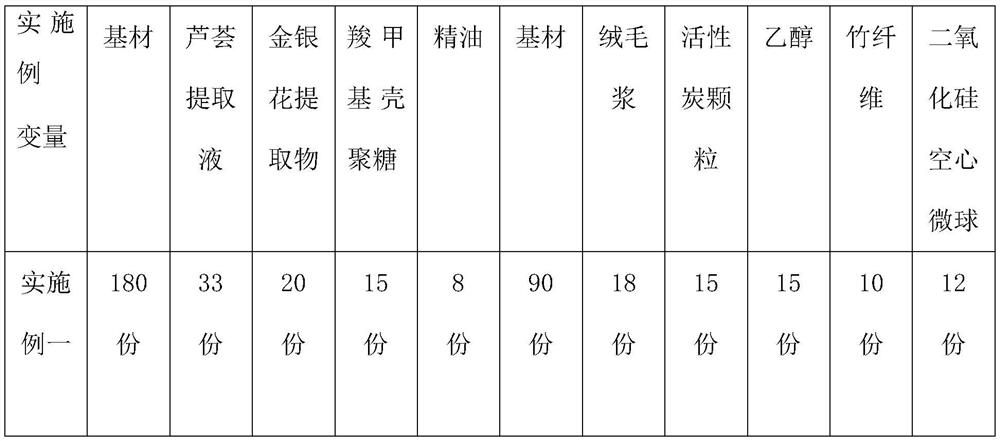

Embodiment 1

[0025] A production process of cotton soft high-elastic diapers, including a surface layer, an absorbent core layer and a leak-proof bottom layer. The leak-proof bottom layer is made of PE breathable microporous film and melt-blown cloth. The surface layer is made of the following raw materials in the weight ratio Composition: 180 parts of substrate, 33 parts of aloe extract, 20 parts of honeysuckle extract, 15 parts of carboxymethyl chitosan, 8 parts of essential oil, the base material of the surface layer is chitin fiber spunlace cloth; the absorbent core layer includes the following weight Proportioned raw materials: 90 parts of base material, 18 parts of fluff pulp, 15 parts of activated carbon particles, 15 parts of ethanol, 10 parts of bamboo fiber, 12 parts of silica hollow microspheres, and the base material of the absorbent core layer is polypropylene, polyester or Any one of nylon non-woven fabrics; the essential oil is oregano essential oil, and the ethanol is absolu...

Embodiment 2

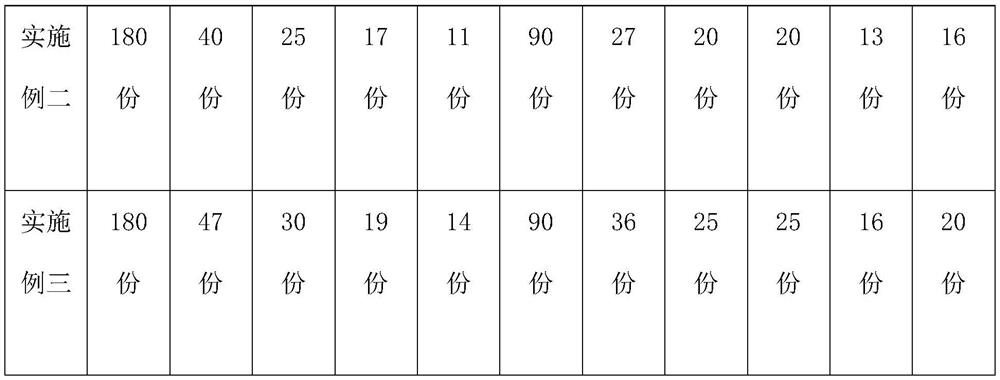

[0032] A production process of cotton soft high-elastic diapers, including a surface layer, an absorbent core layer and a leak-proof bottom layer. The leak-proof bottom layer is made of PE breathable microporous film and melt-blown cloth. The surface layer is made of the following raw materials in the weight ratio Composition: 180 parts of substrate, 40 parts of aloe extract, 25 parts of honeysuckle extract, 17 parts of carboxymethyl chitosan, 11 parts of essential oil, the base material of the surface layer is chitin fiber spunlace cloth; the absorbent core layer includes the following weight Proportioned raw materials: 90 parts of base material, 27 parts of fluff pulp, 20 parts of activated carbon particles, 20 parts of ethanol, 13 parts of bamboo fiber, 16 parts of silica hollow microspheres, and the base material of the absorbent core layer is polypropylene, polyester or Any one of nylon non-woven fabrics; the essential oil is cinnamon essential oil, and the ethanol is abso...

Embodiment 3

[0039] A production process of cotton soft high-elastic diapers, including a surface layer, an absorbent core layer and a leak-proof bottom layer. The leak-proof bottom layer is made of PE breathable microporous film and melt-blown cloth. The surface layer is made of the following raw materials in the weight ratio Composition: 180 parts of base material, 47 parts of aloe extract, 30 parts of honeysuckle extract, 19 parts of carboxymethyl chitosan, 14 parts of essential oil, the base material of the surface layer is chitin fiber spunlace cloth; the absorbent core layer includes the following weight Proportioned raw materials: 90 parts of base material, 36 parts of fluff pulp, 25 parts of activated carbon particles, 25 parts of ethanol, 16 parts of bamboo fiber, 20 parts of silica hollow microspheres, and the base material of the absorbent core layer is polypropylene, polyester or Any one of nylon non-woven fabrics; the essential oil is tea tree essential oil, and the ethanol is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com