Aromatherapy cup with extinguishing module

An aromatherapy cup and aromatherapy technology, which is applied in the parts of lighting devices, dispersed particle filtration, lighting and heating equipment, etc., can solve the problems of choking and difficult to clean.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

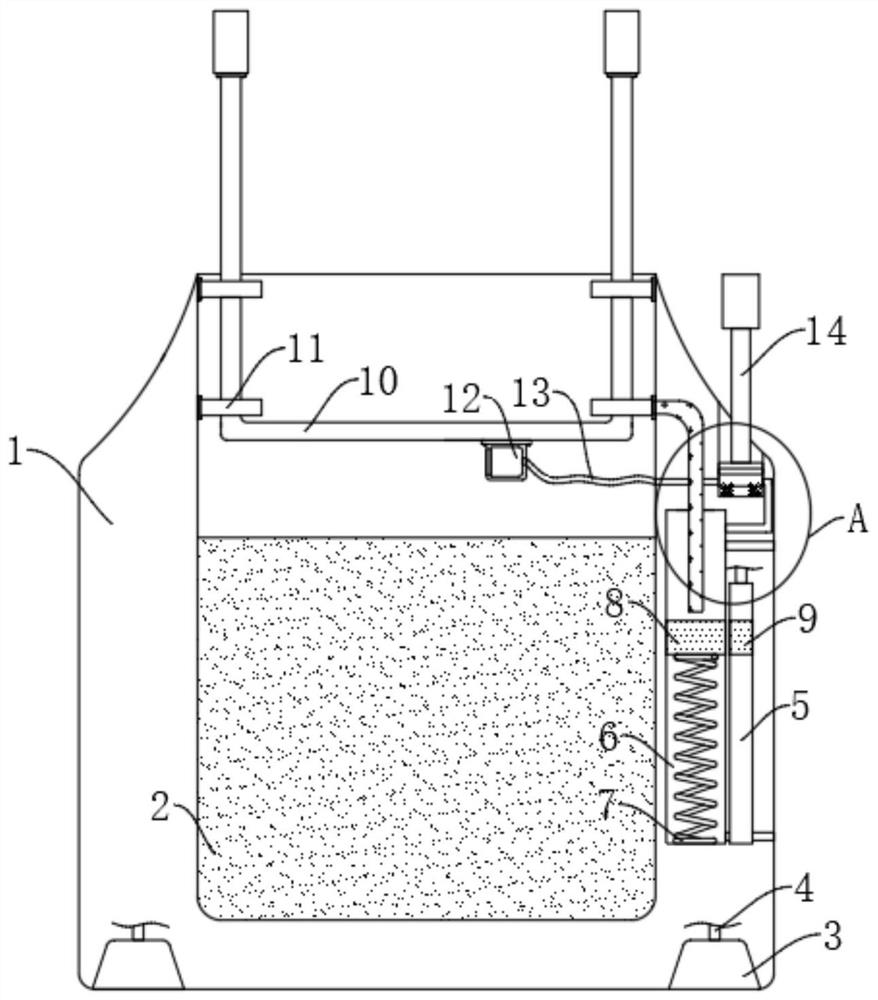

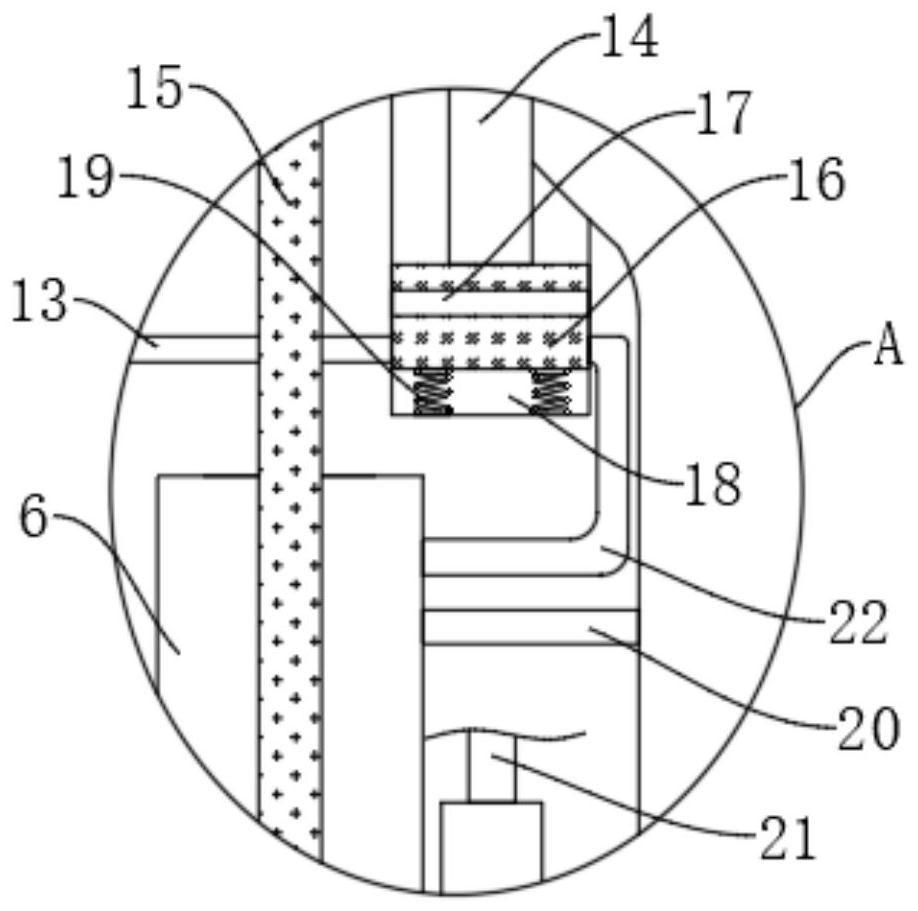

[0026] refer to Figure 1-2 , an aromatherapy cup with an extinguishing module, including a cup body 1, the upper end of the cup body 1 is provided with an installation groove 2, and the cup body 1 is provided with a pressurized chamber 6 and a negative pressure chamber 5, and the pressurized chamber 6 is located in the installation groove 2 The right side of the negative pressure chamber 5 is located on the right side of the booster chamber 6, and the upper end of the cup body 1 is provided with a pressing groove 18;

[0027] The pressurization chamber 6 and the installation groove 2 are jointly provided with a thermal contact module, and the thermal contact module includes a plurality of installation blocks 11 installed on the inner walls of both sides of the installation groove 2, and the adjustment rods 10 are installed on the plurality of installation blocks 11, increasing The pressure chamber 6 is provided with a first magnetic block 8 for sliding up and down. The lower ...

Embodiment 2

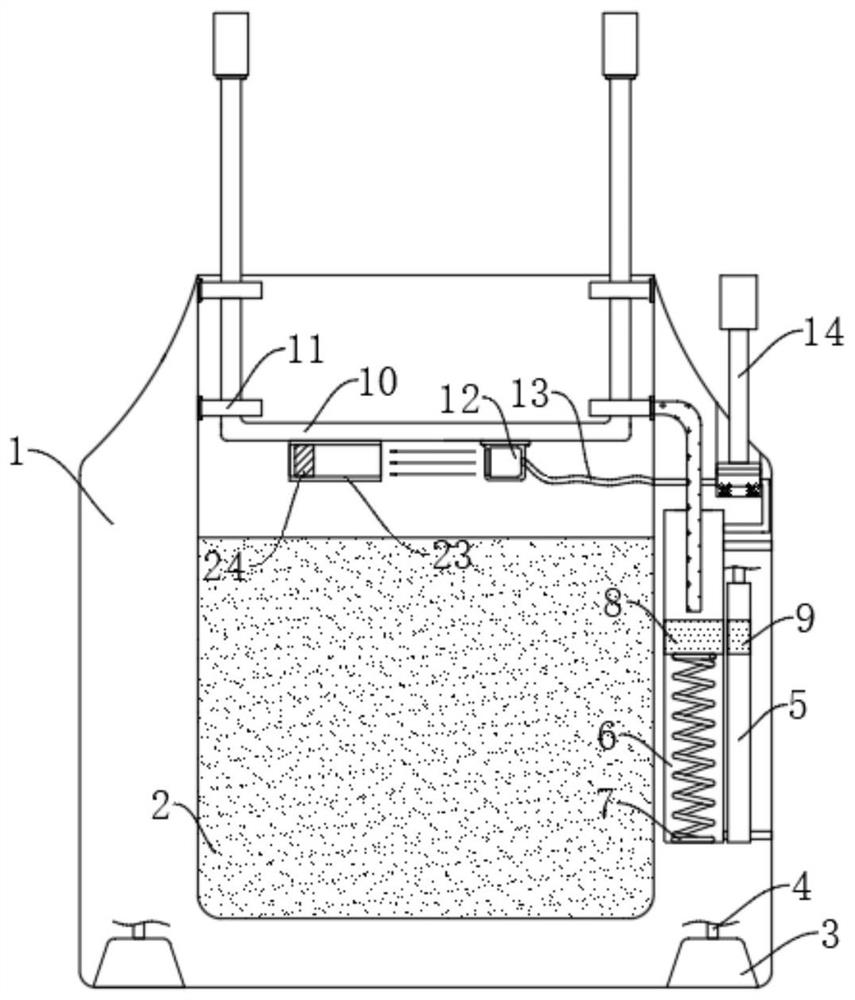

[0038] refer to image 3 , The difference between this embodiment and Embodiment 1 is that a filter box 23 is installed at the lower end of the crossbar, and a through hole 24 is horizontally penetrated in the filter box 23, and a filter element is installed in the through hole 24.

[0039] In this embodiment, after the high-pressure airflow discharged from the air outlet extinguishes the candle, it will continue for a period of time (the user's hand is always pressed on the pressing rod 14). The white smoke is adsorbed to the high-pressure airflow, and then filtered through the filter element in the filter box 23, and then discharged from the left side of the port 24 to completely filter the white smoke.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com