Heat source shunting type waste heat power generation system and optimization control method thereof

A waste heat power generation and optimization control technology, applied in system integration technology, design optimization/simulation, information technology support system, etc., can solve problems such as large net output power, unorganic Rankine cycle simulation and optimization, and difficulty in obtaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention are described below so that those skilled in the art can understand the present invention, but it should be clear that the present invention is not limited to the scope of specific embodiments. For those of ordinary skill in the art, as long as various changes Within the spirit and scope of the present invention defined and determined by the appended claims, these changes are obvious, and all inventions and creations using the concept of the present invention are included in the protection list.

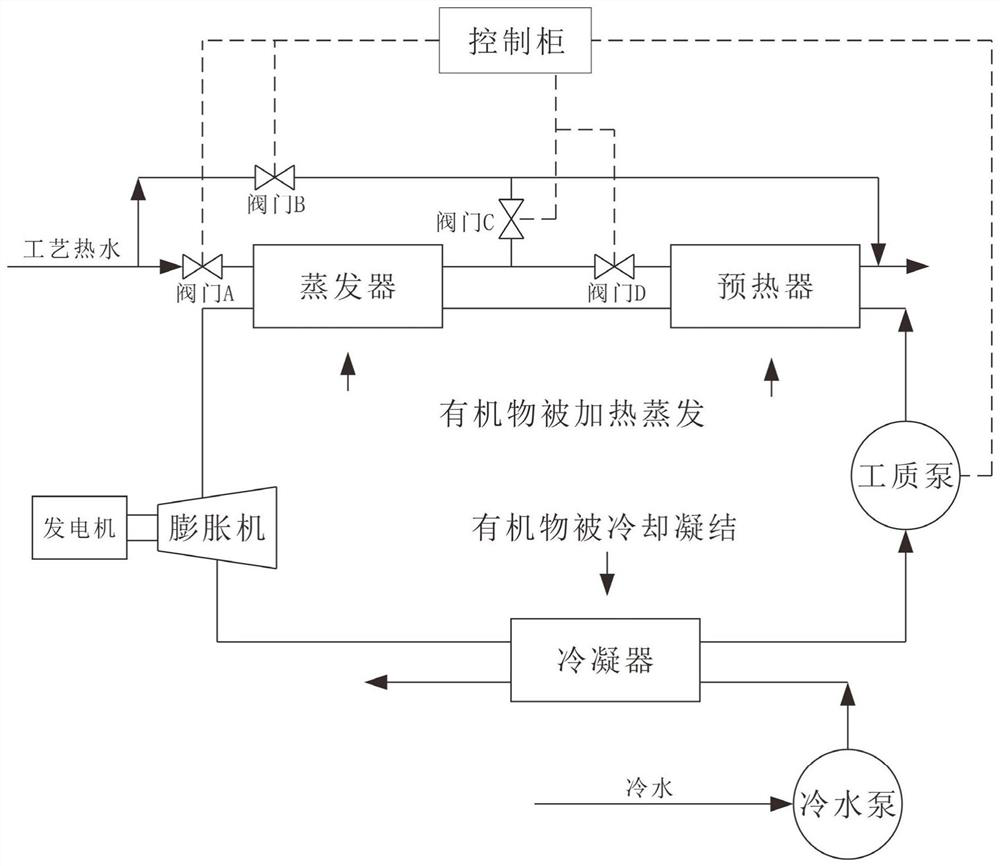

[0028] like figure 1 As shown, the heat source split waste heat power generation system of this scheme includes an evaporator and a preheater, the hot end inlet of the evaporator is connected to the process hot water inlet pipe, and the hot end outlet of the evaporator is connected to the hot end inlet of the preheater; The hot end outlet of the preheater is connected to the process hot water outlet pipe; the cold end inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com