Concrete vibrating, paving and leveling device

A leveling device and concrete technology, applied in shaft equipment, earthwork drilling, wellbore lining, etc., can solve the problems of high labor intensity, high labor cost, narrow space, etc., to improve the controllability of construction quality and improve operation. Efficiency and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

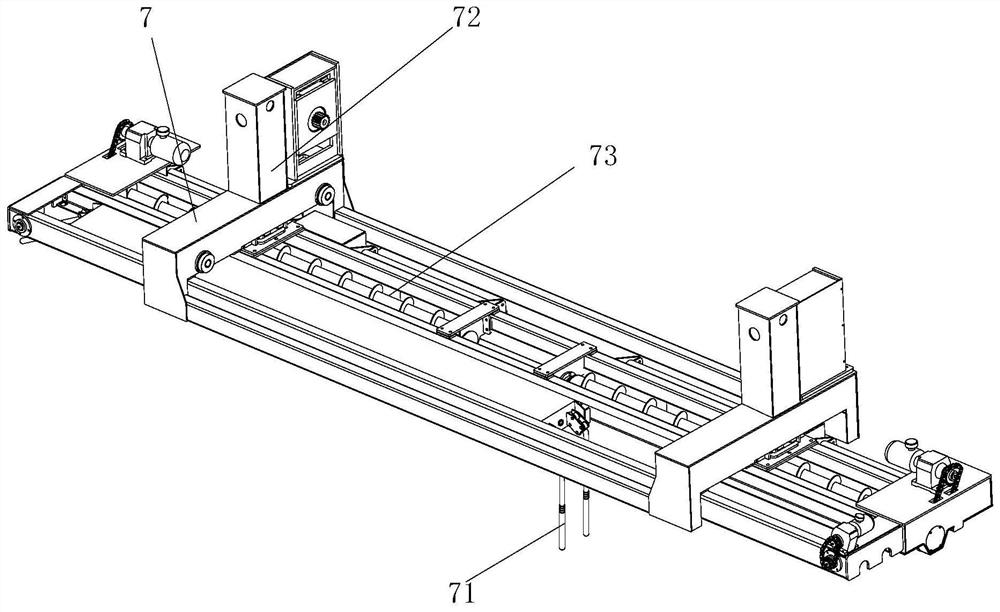

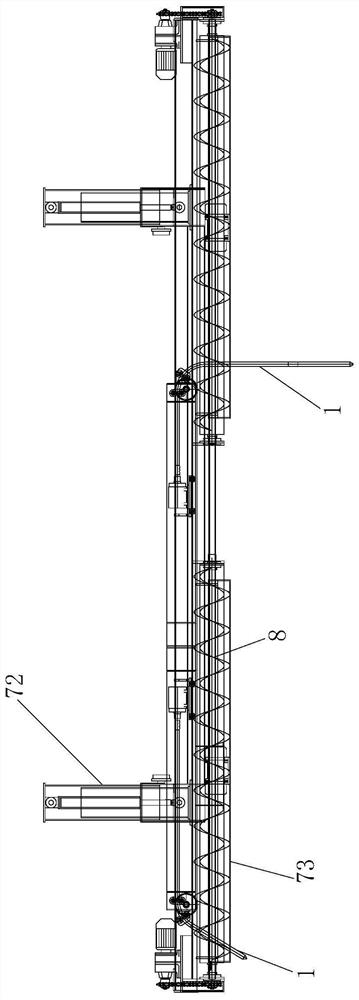

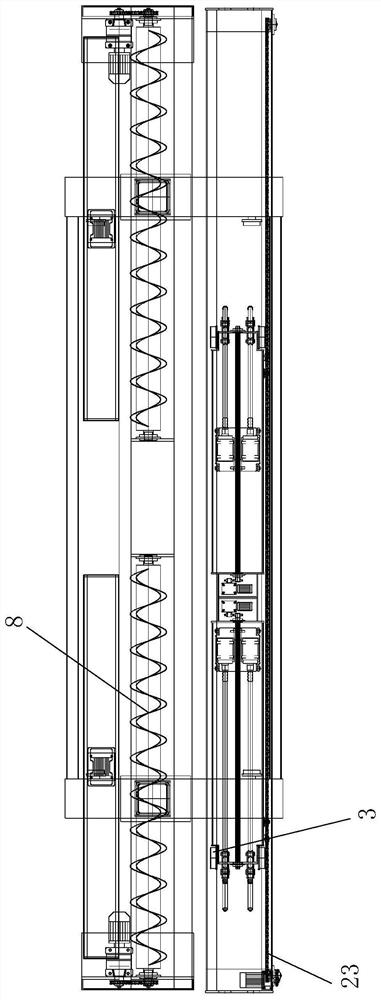

[0026] Figure 1 to Figure 7 An embodiment of the concrete vibrating paving and leveling device of the present invention is shown. The tunnel concrete vibrating paving and leveling device of this embodiment includes a frame 7, a vibrating mechanism 71 arranged on the frame 7 and The lifting adjustment mechanism 72 and the paving leveling structure 73 connected with the lifting adjustment mechanism 72, the vibrating mechanism 71 includes a vibrating rod 1, a track 2 arranged on the frame 7 and a mobile trolley 3 arranged on the track 2, The mobile trolley 3 is provided with a vibrating driver 4, a vibrating rod guide 5, and a vibrating trolley 6 for driving the vibrating driving part 4 to reciprocate, the vibrating rod 1 is connected with the vibrating driving part 4, and the vibrating The driver 4 is arranged on the vibrating trolley 6 . Wherein, the vibrator guide 5 can be, for example, a pair of guide wheels, and the vibrator 1 is sandwiched between the pair of guide wheels...

Embodiment 2

[0036] Figure 8 Another embodiment of the concrete vibrating paving and leveling device of the present invention is shown. The tunnel concrete vibrating paving and leveling device of this embodiment is basically the same as the first embodiment, the difference is: in this embodiment, The paving and leveling mechanism 73 includes a spiral paving drum 8 and a leveling drum 20. The spiral paving drum 8 is located between the vibrating mechanism 71 and the leveling drum 20. The surface is further smoothed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com