Telescopic device capable of being rapidly installed

A telescopic device, a fast technology, applied in the erection/assembly of bridges, pavement details, buildings, etc., can solve the problems affecting the service life and maintenance cost of the telescopic device, the long construction period of the installation process, and the difficulty in controlling the welding quality. The effect of maintenance cost, improving service life and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

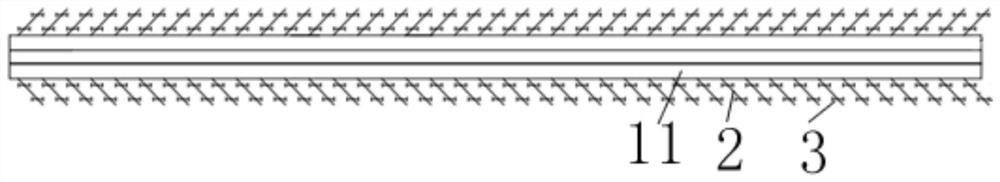

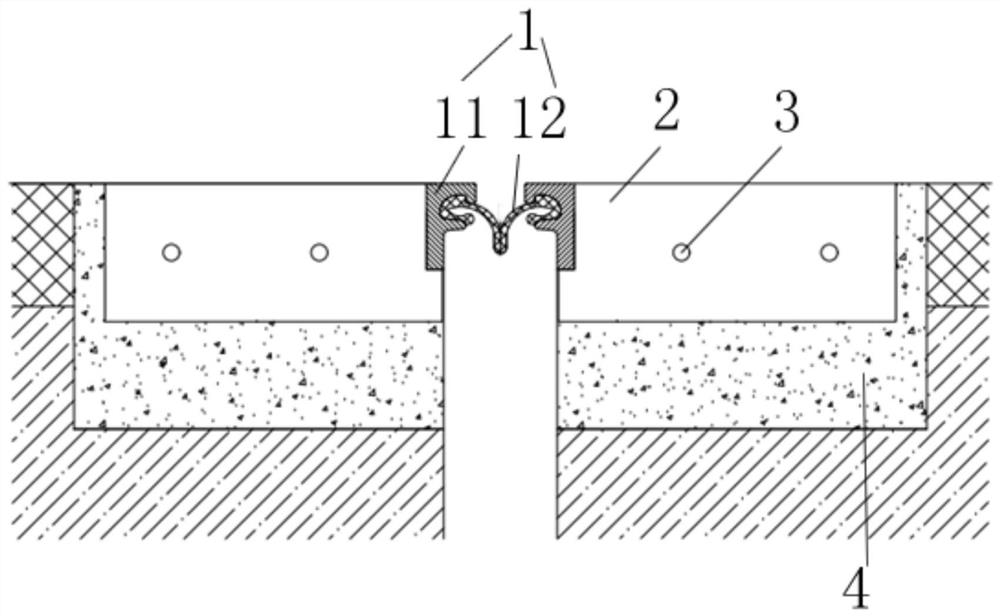

[0028] like Figure 1-2 As shown, a telescopic device that can be quickly installed includes a telescopic device body 1. The telescopic device body 1 includes two side beams 11 arranged symmetrically. The side beams 11 are made of F-shaped steel, and a sealing rubber is connected between the two side beams 11. The bar 12 and the opposite sides of the two side beams 11 are respectively provided with a plurality of long anchor plates 2 distributed side by side at equal distances along the length direction. The top surface of the side beam 11 is flush with the top surface of the long anchor plate 2 . The long anchor plate 2 is provided with several rivets 3 . Compared with the traditional telescopic device, the telescopic device of the present invention does not need welding steps, and can be poured after hoisting and fixing, saving a lot of construction time, manpower, material resources and financial resources.

[0029] Specifically, the long anchor plate 2 is arranged obliqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com