Four-axis synchronous lifting mechanism with protection function

A technology with synchronous lifting and protection functions, applied in the direction of lifting frame, lifting device, etc., can solve the problems of no safety protection measures, low lifting displacement accuracy, small load weight, etc., to reduce safety hazards, avoid safety hazards, and improve Ability-boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

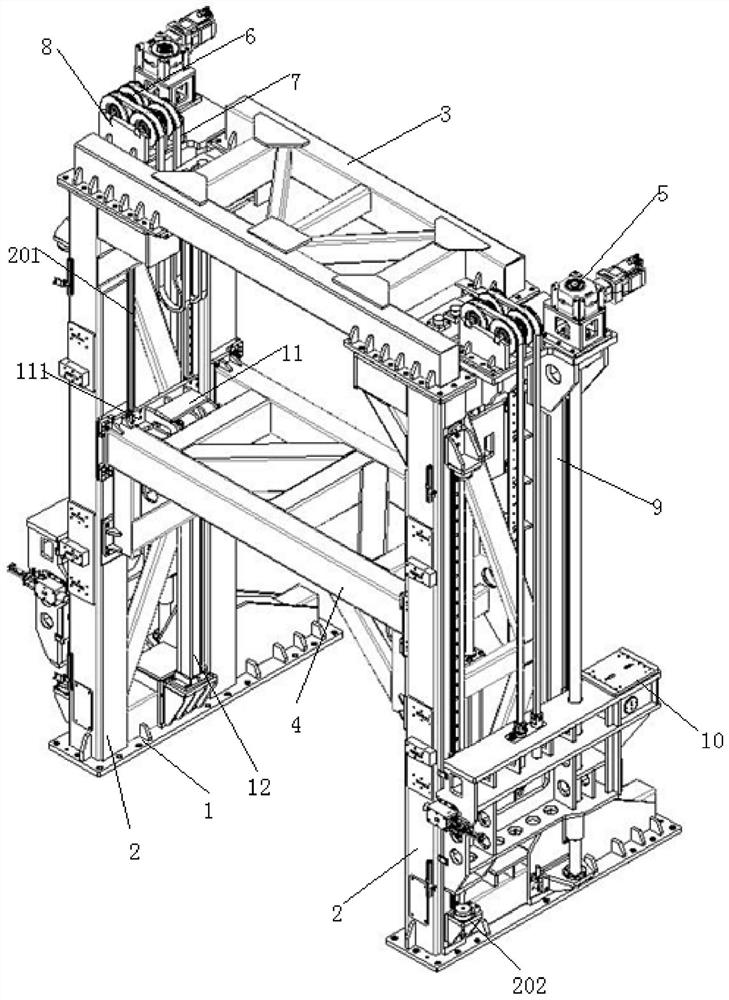

[0022]The present invention will be further described below with reference to the accompanying drawings.

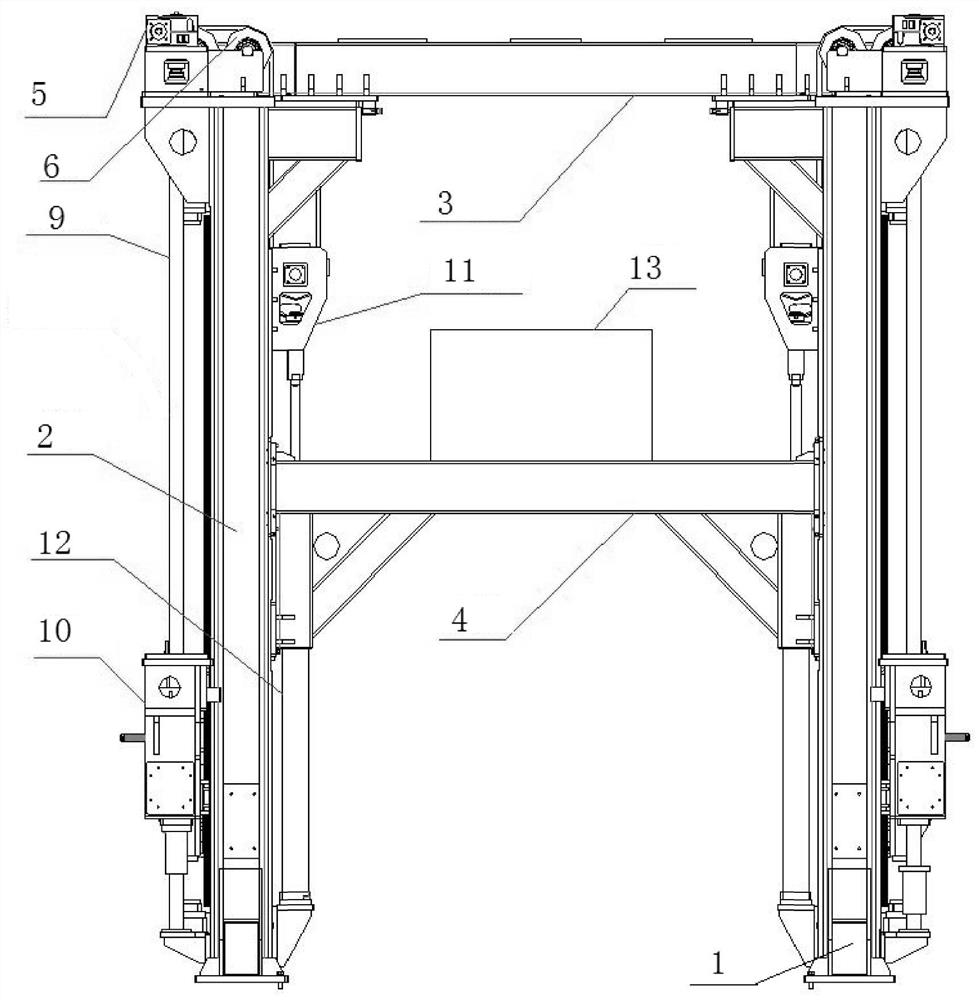

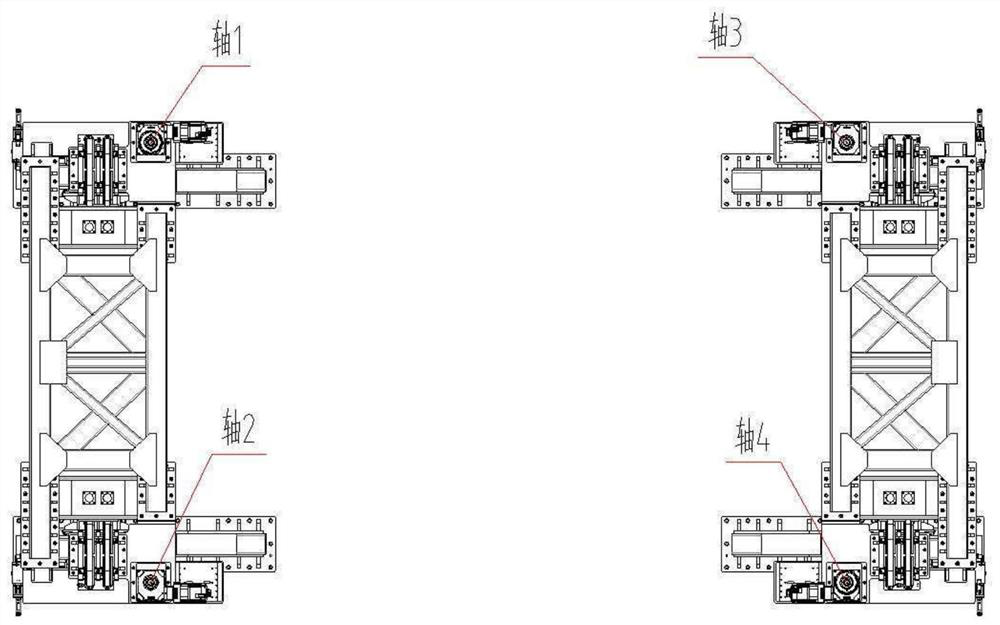

[0023]Such asfigure 1 ,figure 2 withimage 3As shown, the four-axis synchronous lifting mechanism having the protection function of the present application includes a 2 set of synchronous lifting mechanisms, the synchronous lifting mechanism includes a support structure, a power device, a boosting device, and a hydraulic fitting device including a base 1, a support post 2, The connecting beam 3 and the connecting band 4, the support structure is provided with two base 1, and the base 1 is provided with a bolt hole, and the user can fix the base 1 on the bottom surface or to improve the support and stability. Moreover, the upper end of the base 1 is provided with the top end of the support column 2, and the intermediate setting of the connecting beam is 2, the two support column 2 is provided with a connecting rib 4. The connecting beam 2 and the connecting band 4 provide sufficient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com