DMP-based robot bolt screwing method and system

A robot and bolt technology, applied in the field of machine learning, can solve problems such as incomplete data, achieve strong coding ability and noise processing ability, and facilitate skill learning and reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

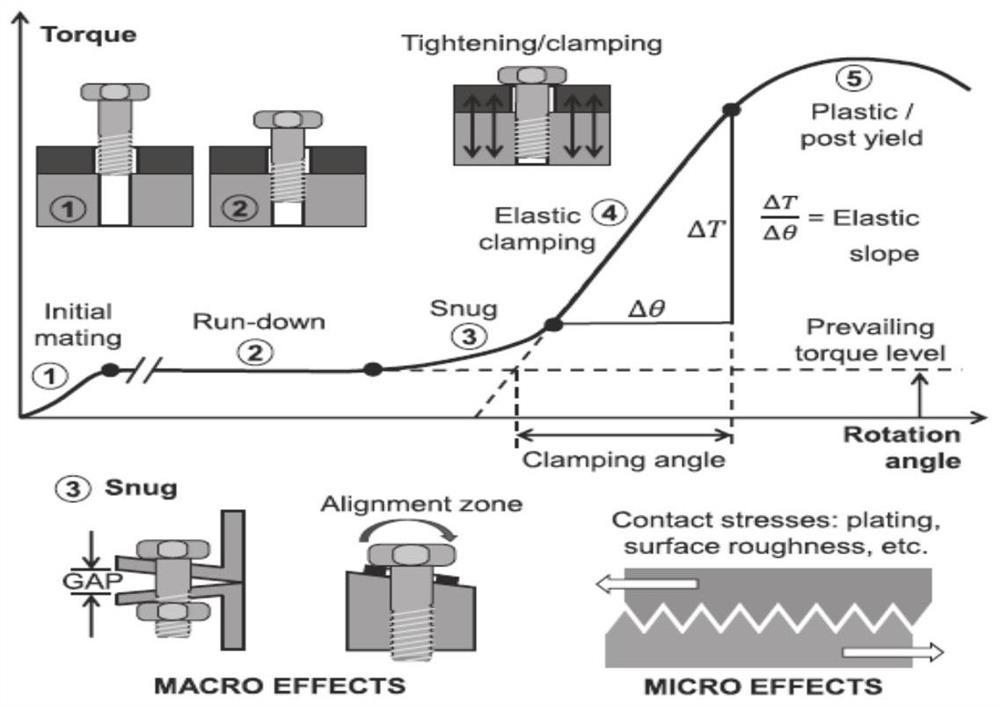

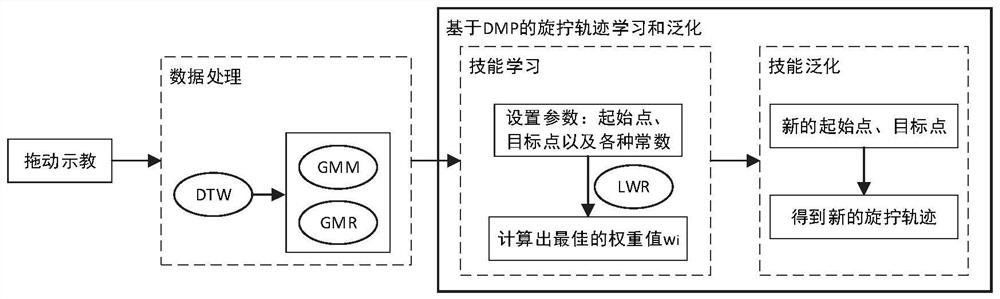

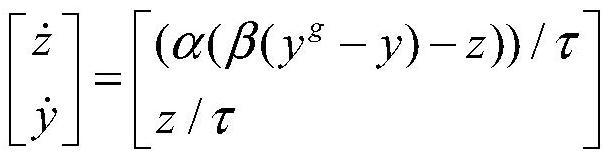

[0036] This embodiment discloses a DMP-based robot bolt screwing method. The DMP-based robot bolt screwing skill learning method is mainly to teach and code the robot's screwing path during the process of the robot screwing a bolt. and the process of generalization. Firstly, the long bolt locking process is segmented into five stages to understand the characteristics of the screwing force at different stages. Based on DMP, the screwing trajectory of the first four stages is taught and learned and Generalization, so that the robot can learn the skill of screwing bolts.

[0037] The process of bolt screwing can be mainly divided into five stages, one way to visualize this process is by plotting the applied torque against the total rotation angle to produce a torque angle curve, as figure 1 shown. The first stage is the first section of the curve, which is the initial contact stage of the bolt and nut. This process is mainly the process of the bolt and nut just contacting and th...

Embodiment 2

[0104] The purpose of this embodiment is to provide a computing device, including a memory, a processor, and a computer program stored in the memory and operable on the processor. When the processor executes the program, the method in the first embodiment above is implemented. specific steps.

Embodiment 3

[0106] The purpose of this embodiment is to provide a computer-readable storage medium.

[0107] A computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, specific steps for implementing the method in Example 1 are executed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com