Detection module and detection method for intelligent production line system for pipette tip

A pipette head and production line technology, applied in the field of pipette head detection, can solve the problems of low detection efficiency of pipette head, and achieve the effects of avoiding tilt, high detection efficiency, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

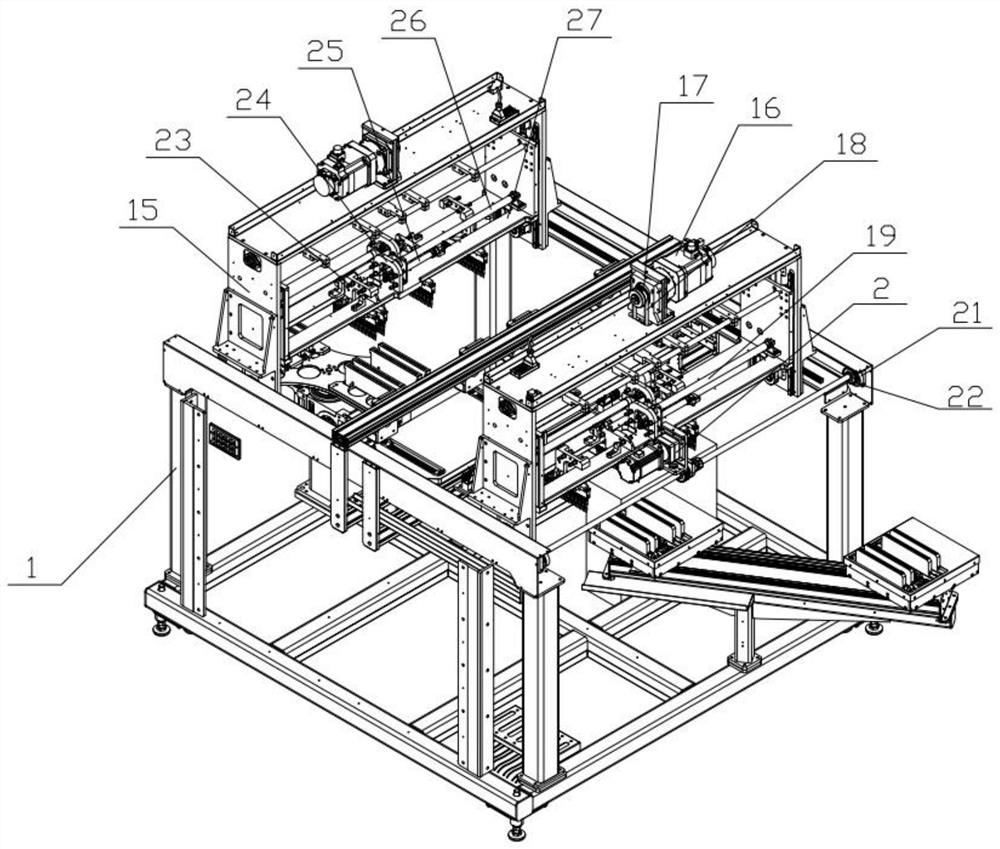

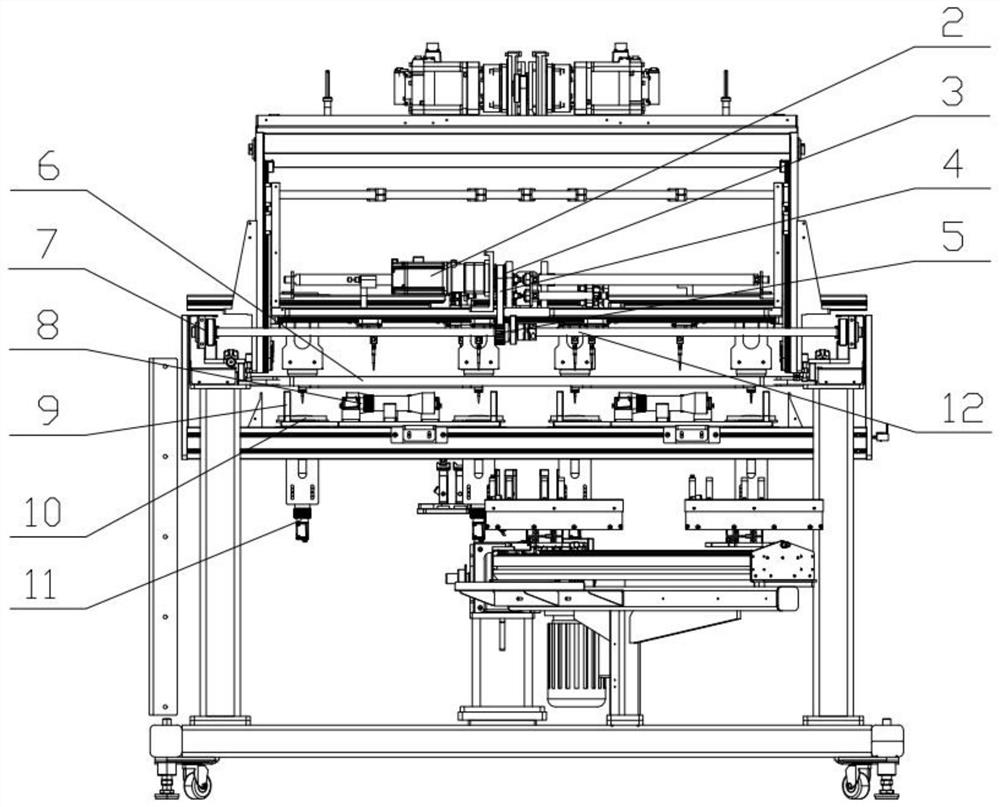

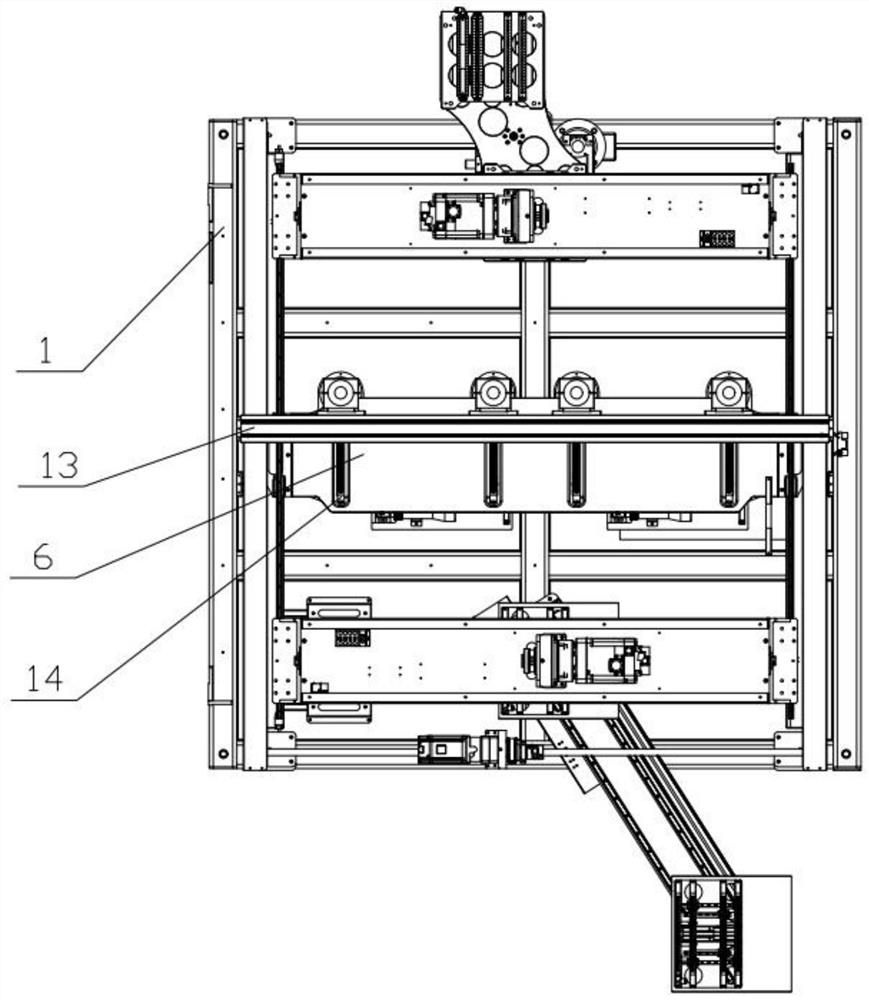

[0031] A detection module of a liquid pipetting head intelligent production line system, including a frame 1, a handling unit and a detection unit; the number of carrying units is 2, which are respectively arranged at both ends of the frame 1; the detection unit includes a detection slide carrying a pipetting head platform and a visual detection device for checking the defects of the liquid pipetting head, the visual detection device is fixedly connected to the frame 1 through the fixed frame 13; the detection sliding table is slidably arranged on the frame 1; the detection sliding table drives the liquid pipetting head to detection device.

[0032] Wherein, the two conveying units are respectively used for conveying the pipette head to be detected from the previous process to the detection unit, and conveying the pipette head which has been detected by the detection unit to the next process.

[0033] In this embodiment, the detection slide includes a first driving device, a p...

Embodiment 2

[0061] A detection method for a liquid pipetting head intelligent production line system, using the detection module of the liquid pipetting head intelligent production line system provided in Embodiment 1, the detection method comprising the following steps:

[0062] In the feeding step, the material enters the feeding station through the handling device;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com